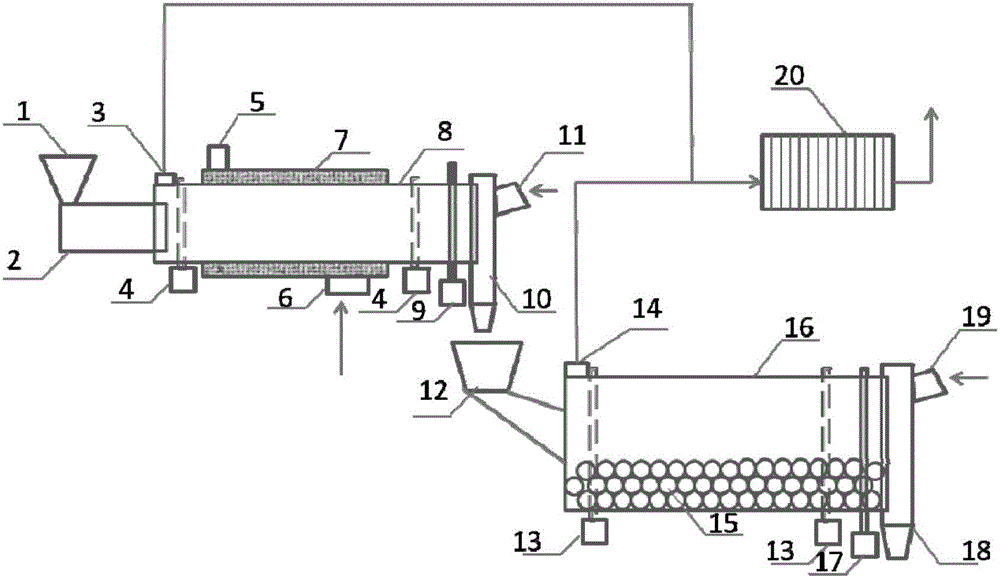

Contaminated soil repair system and method

A technology for polluting soil and repairing the system, applied in the field of environmental protection, can solve the problems of restricting the application of mechanical ball milling, high noise, etc., and achieve the effect of avoiding long and complicated process, no secondary pollution, and avoiding dioxins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] In a site polluted by heavy metal arsenic, the average concentration of arsenic in the contaminated soil was 122 mg / kg. After air-drying and sieving, polluted soil with a particle size of <5mm is obtained, which is sent to a low-temperature rotary kiln by a screw conveyor, dried at 105°C for 60 minutes, and then enters the drum of a ball mill. Control the soil feeding speed to keep the ball-to-soil mass ratio between 6:1 and 3:1, the rotating speed of the ball mill drum is 15r / min, and the soil ball milling time is 60min. Analyze the treated soil samples according to US EPA SW 846 Method The 1312 method carried out the leaching test on the soil before and after the ball milling treatment, and analyzed the concentration of arsenic in the leachate by ICP-OES. The arsenic concentrations in the leachate before and after the ball milling treatment were measured to be 3.3mg / L and 0.03mg / L respectively, which reached the groundwater quality standard (GB / T 14848-93) Class III ...

Embodiment 2

[0060] In a site polluted by heavy metal lead, the average concentration of lead in the polluted soil was 1120mg / kg. After air-drying and sieving, polluted soil with a particle size of <5mm is obtained, which is sent to a low-temperature rotary furnace through a screw conveyor, dried at 110°C for 30 minutes, and then enters the drum of a ball mill. Control the speed of soil entry so that the mass ratio of balls to soil is kept at 10:1~1:1, the rotating speed of the ball mill drum is 10~15r / min, and the soil ball milling time is 30min. The treated soil samples are analyzed according to US EPA SW The 846 Method 1312 method carried out the leaching test on the soil before and after the ball milling treatment. The lead concentration in the leachate was analyzed by ICP-OES, and the lead concentration in the leachate before and after the ball milling treatment was measured to be 42mg / L and 0.01mg / L respectively, which reached the groundwater quality standard (GB / T 14848-93) Class I...

Embodiment 3

[0062] In a PCBs (polychlorinated biphenyls) contaminated site, the total concentration of PCBs congeners in the contaminated soil was 830mg / kg. After air-drying and screening, the contaminated soil with a particle size of <2mm is mixed with a certain amount of additives, and then sent to a low-temperature rotary furnace through a screw conveyor, dried at 80°C for 5 hours, and then entered into the drum of a ball mill. Control the speed of soil entry so that the mass ratio of balls to soil is kept at 6:1-3:1, the rotating speed of the ball mill drum is 20-40r / min, and the soil ball milling time is 5h min. The treated soil is sampled and extracted with dichloromethane ultrasonically. Afterwards, the extract was purified according to the US EPA 1668A standard method, and finally quantitatively analyzed by GC-MS. It was measured that the concentration of PCBs in the soil after ball milling treatment was 9.1 mg / kg, and the removal rate of PCBs reached 98.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com