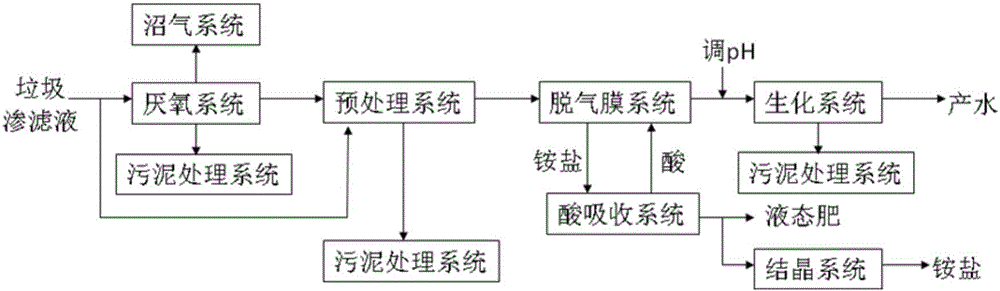

Landfill leachate treatment process and special equipment thereof

A landfill leachate and treatment process technology, which is applied in the field of wastewater treatment, can solve the problems of high investment, difficult discharge standards, and high energy consumption, and achieve the effects of improving ammonia nitrogen discharge standards, alleviating pollution problems, and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

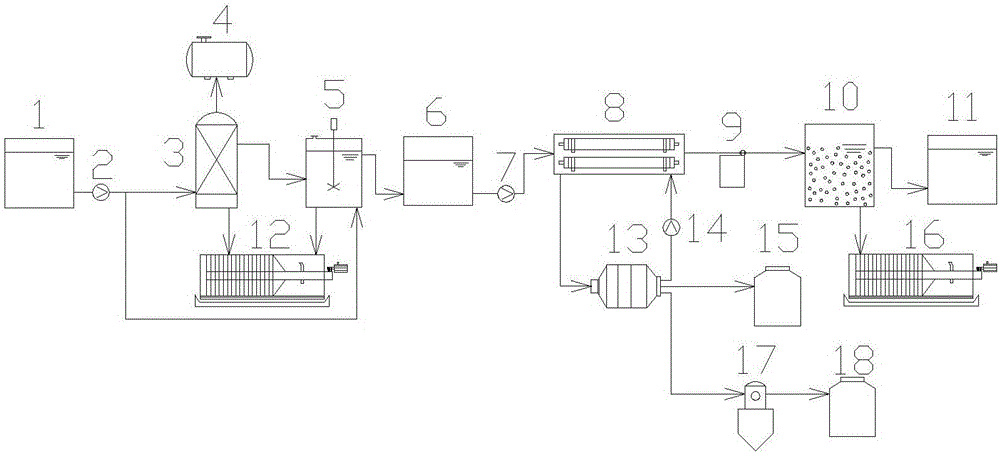

[0025] As attached figure 2 As shown, a special equipment for the treatment process of landfill leachate includes a raw water tank 1, a first inlet pump 2, an anaerobic reaction tank 3, a biogas collection system 4, a pretreatment reactor 5, an intermediate water tank 6, and a second inlet Water pump 7, membrane contactor unit 8, dosing pump 9, biochemical reaction tank 10, produced water tank 11, first sludge treatment system 12, acid absorption tank 13, acid absorption pump 14, first product tank 15, second sewage Sludge treatment system 16, crystallization device 17, and second product tank 18;

[0026] The raw water tank 1 is connected to the anaerobic reaction tank 3, the connecting pipeline is equipped with a first water inlet pump 2, the outlet end of the anaerobic reaction tank 3 is connected to the pretreatment reactor 5, and the sludge output end is connected to the first sludge treatment system 12. The biogas output end is connected to the biogas collection system 4,...

Embodiment 2

[0028] When the feed is landfill leachate, the raw water tank can also be directly connected to the pretreatment reactor 5.

[0029] The process of using the above-mentioned special equipment for landfill leachate treatment includes the following steps:

[0030] (1) The waste leachate of the incineration plant is anaerobic treated to obtain the anaerobic treated effluent. If it is landfill leachate, the anaerobic treatment will not be carried out and go directly to the next step; the COD content of the anaerobic treated effluent is 3000 -5000mg / L, NH 3 -N content is 1500-3000mg / L, hardness is 1000-2000mg / L, alkalinity is 6000-12000mg / L, and pH is in the range of 6.5-8.5.

[0031] (2) Pretreat the effluent obtained in step (1) to obtain chemical pretreatment effluent; the pretreatment is performed by adding lime CaOH 2 Or sodium hydroxide NaOH adjusts the pH to the range of 10-12 to perform a sufficient reaction to convert the ammonium ion in the wastewater into free ammonia, and remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com