Emulsified asphalt and preparation method thereof

A technology of emulsified asphalt and emulsifier, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of short service life, thin construction thickness and poor comprehensive performance of pavement, and achieve improved service life, strong bond strength, The effect of improving surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] According to a preferred mode of the present invention, the preparation method of the emulsified asphalt comprises:

[0042] (1) In the presence of a compatibilizer and a stabilizer, the base asphalt is mixed with a polymer modifier to prepare a polymer modified asphalt at 170-180°C;

[0043] (2) Mix the emulsifier, anti-stripping agent and water to obtain a soap solution at 55-65°C, and adjust the pH value of the obtained soap solution to 1.8-2.2;

[0044] (3) Mixing and emulsifying the polymer modified bitumen obtained in step (1) and the soap liquid obtained in step (2).

[0045] According to the method of the present invention, the types of the base asphalt, polymer modifier, emulsifier, anti-stripping agent, stabilizer and compatibilizer are the same as those described above, and will not be repeated here. The amount of base asphalt, polymer modifier, emulsifier, anti-stripping agent, stabilizer, water and compatibilizer is such that the content of each component ...

Embodiment 1

[0053] This example is used to illustrate the emulsified asphalt and its preparation method according to the present invention.

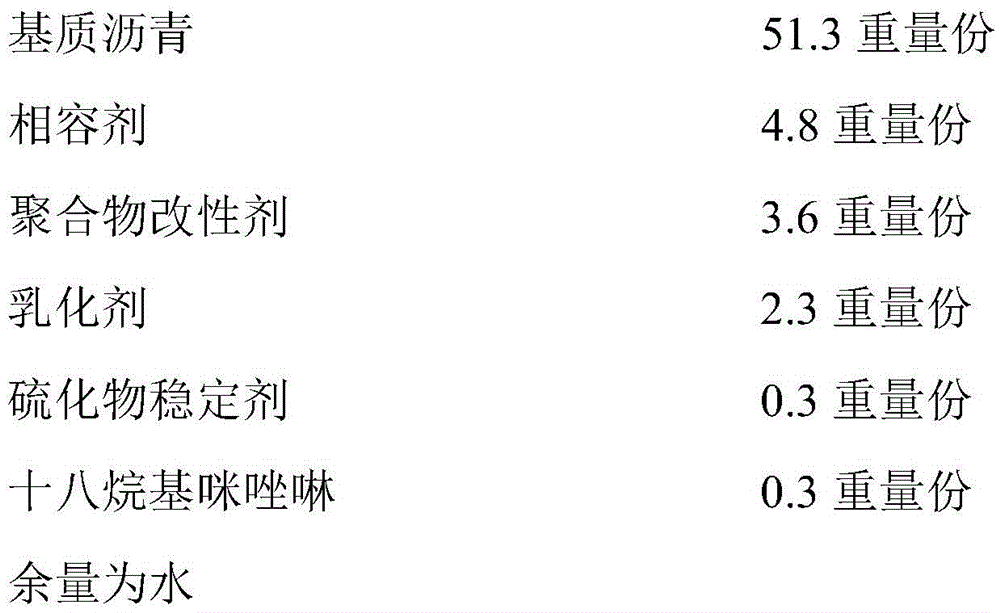

[0054] The composition formula (by weight) of emulsified asphalt:

[0055]

[0056] Among them, the base asphalt is No. 70 road asphalt commercially purchased from Zhenhai Refining and Chemical Co., Ltd., with a penetration of 68.1; the polymer modifier is styrene-butadiene-styrene ternary compound commercially available from Yueyang Petrochemical Co., Ltd. (SBS791H). Copolymer, wherein, based on the total amount of styrene-butadiene-styrene terpolymer, the content of the structural unit formed by styrene is 30% by weight, and the content of the structural unit formed by butadiene is 70% by weight; the average molecular weight of the styrene-butadiene-styrene terpolymer is 110,000;

[0057] The compatibilizer is an aromatics extraction oil (commercially purchased from Jinan Oil Refinery) with an aromatics content of 92% by weight;

[0058] The ...

Embodiment 2

[0076] This example is used to illustrate the emulsified asphalt and its preparation method according to the present invention.

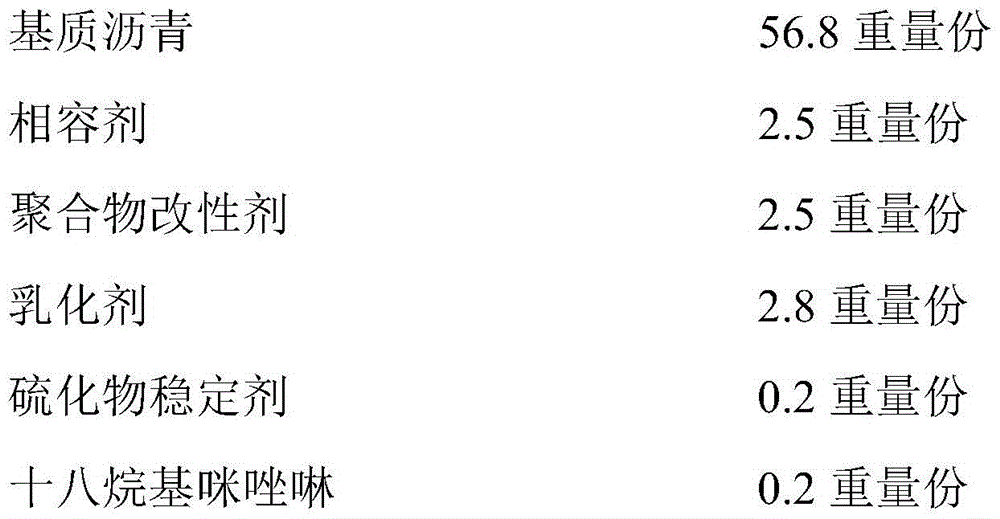

[0077] The composition formula (by weight) of emulsified asphalt:

[0078]

[0079]

[0080] Among them, the base asphalt is No. 70 road asphalt commercially purchased from Zhenhai Refining and Chemical Co., Ltd., with a penetration of 68.1;

[0081] The polymer modifier is a styrene-butadiene-styrene terpolymer commercially available from Yueyang Petrochemical under the brand name SBS791H, wherein the total amount of the styrene-butadiene-styrene terpolymer is Standard, the content of the structural unit formed by styrene is 30% by weight, the content of the structural unit formed by butadiene is 70% by weight; the average molecular weight of this styrene-butadiene-styrene terpolymer is 11 Ten thousand;

[0082] The compatibilizer is furfural extracted oil (commercially purchased from Jinan Oil Refinery) with an aromatics content of 92% by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com