Novel tobacco product of tobacco cocoa liquor and preparation method thereof

A technology of cocoa wine and tobacco, applied in the field of smokeless tobacco, to achieve the effect of large industrial application prospects and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

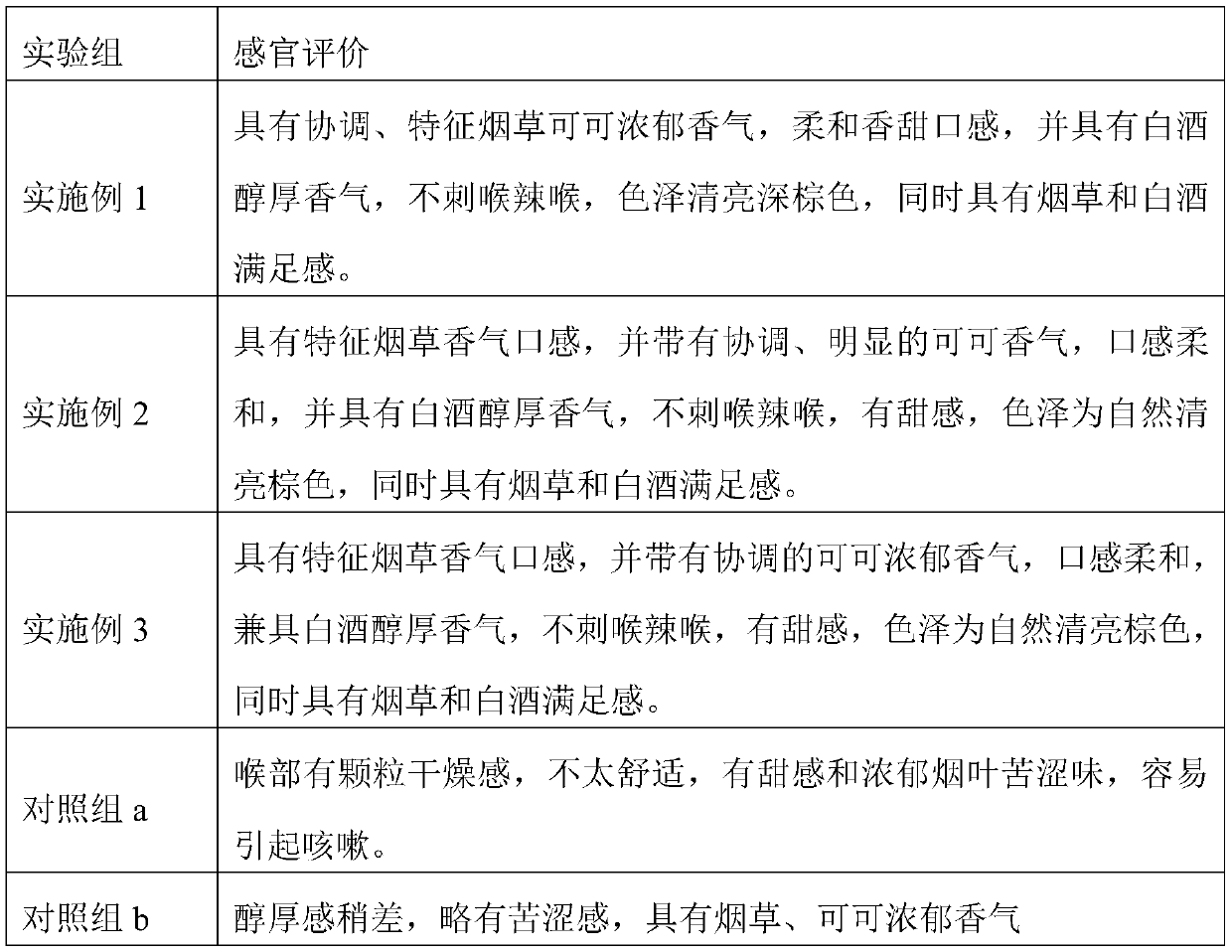

Examples

Embodiment 1

[0024] A novel tobacco product of tobacco cocoa liquor, which uses high-quality Yunnan tobacco leaf superfine powder and cocoa bean powder as raw materials, and specifically includes the following steps:

[0025] (1) Preparation of tobacco cocoa fermented wine: mix high-quality Yunnan tobacco leaf powder, cocoa powder, and white sugar at a mass ratio of 1:2:20, add 10 times distilled water, cook at 100°C for 30 minutes, concentrate until the sugar content reaches 160g / L, add The mass ratio of the above-mentioned smoke powder, cocoa powder and powdered sugar mixture is 0.01% pectinase (food grade, enzyme activity 20000u / g) and 0.01% β-glucosidase (food grade, enzyme activity 10,000u / g), Then add an appropriate amount of lactic acid and sodium bicarbonate to adjust the pH to 4.2, inoculate the active dry yeast with a mass ratio of 0.03% of the mixture, stir evenly, and carry out alcoholic fermentation at a controlled temperature of 25°C for 8 days. When the alcohol content does n...

Embodiment 2

[0032] A novel tobacco product made of tobacco cocoa wine, which uses high-quality Zimbabwean tobacco leaf powder and cocoa bean powder as raw materials, and specifically includes the following steps:

[0033](1) Preparation of tobacco cocoa fermented wine: mix high-quality Zimbabwean tobacco powder, cocoa powder, and glucose at a mass ratio of 1:1.5:15, add 8 times of water, cook at 100°C for 25 minutes, concentrate until the sugar content reaches 145g / L, add the above Smoke powder, cocoa powder and sugar powder mixture mass ratio 0.01% pectinase (food grade, enzyme activity 10,000 u / g) and 0.005% mass ratio of β-glucosidase (food grade, enzyme activity 5000u / g) , then add an appropriate amount of citric acid and sodium bicarbonate to adjust the pH to 4.8, inoculate Saccharomyces cerevisiae with a mass ratio of 0.02% of the mixture, stir evenly, and carry out alcoholic fermentation at a controlled temperature of 28°C for 9 days. When the alcohol content does not change for two...

Embodiment 3

[0040] A novel tobacco product made of tobacco cocoa liquor, which uses high-quality Yunnan tobacco leaf powder and cocoa powder as raw materials, and specifically comprises the following steps:

[0041] (1) Preparation of tobacco cocoa fermented wine: mix high-quality Yunnan tobacco powder, cocoa powder, and xylose in a mass ratio of 1:1:5, add 5 times of distilled water, cook at 100°C for 20 minutes, concentrate until the sugar content reaches 100g / L, add Above-mentioned tobacco powder, cocoa powder and powdered sugar mixture mass ratio 0.02% pectinase (food grade, enzyme activity 8000u / g) and mass ratio 0.01% beta-glucosidase (food grade, enzyme activity 1000u / g), then Add appropriate amount of lactic acid and sodium bicarbonate to adjust the pH to 5.0, inoculate active dry yeast with a mass ratio of 0.01% of the mixture, stir evenly, and carry out alcoholic fermentation at a temperature of 22°C for 10 days. When the alcohol content does not change for more than two consecut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com