Transmission device and stirring tank suitable for stirring tobacco perfume

A transmission device and spice technology, applied to mixers with rotating agitation devices, mixer accessories, transportation and packaging, etc., can solve the problems of silk production quality in workshops, hidden dangers in production safety, difficulty in finding oil leakage in reducers, and easy spontaneous combustion, etc. problems, to achieve the effect of improving production stability, simple structure setting, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

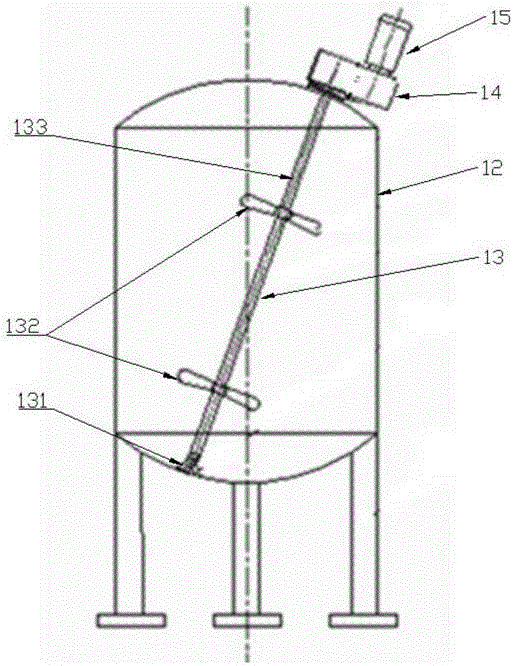

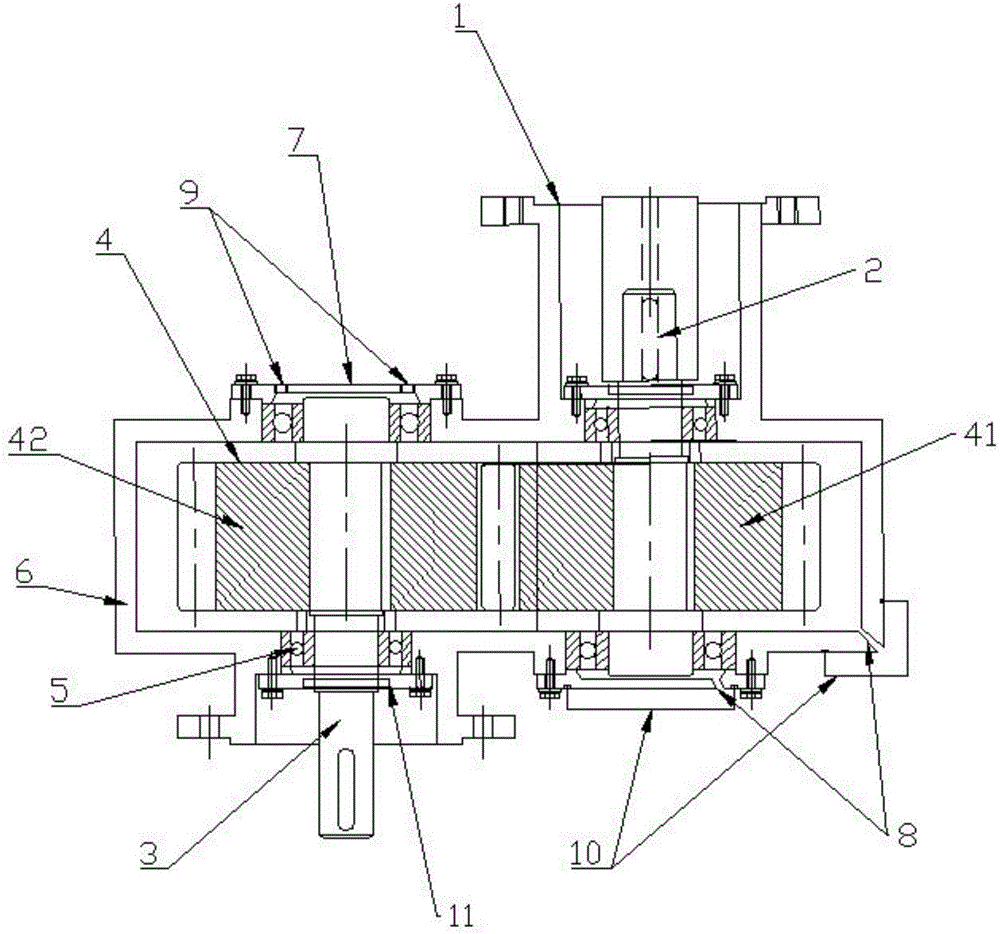

[0031] A transmission device suitable for stirring tobacco spices, including a gear box 1, an input shaft 2 and an output shaft 3, the gear box 1 includes a gear set 4, a bearing 5 and a casing 6, and the gear set 4 communicates with the gear box through the bearing 5 The box body 6 is connected in rotation, the gear set 4 includes an input gear 41 and an output gear 42, the input gear 41 is fixedly connected to the input shaft 2, and the output gear 42 is fixedly connected to the output shaft 3, The output gear 42 is in driving connection with the input gear 41 , and makes the axis of the input shaft 2 offset from the axis of the output shaft 3 .

[0032] In this embodiment, gear set 4 can be used for transmission, so that the input shaft 2 and the output shaft 3 are prevented from being located in the same axial direction, and the high-temperature flue gas in the tank rises and directly rushes to the input shaft 3, corrodes the motor 15, and causes oil leakage. And, once the...

Embodiment 2

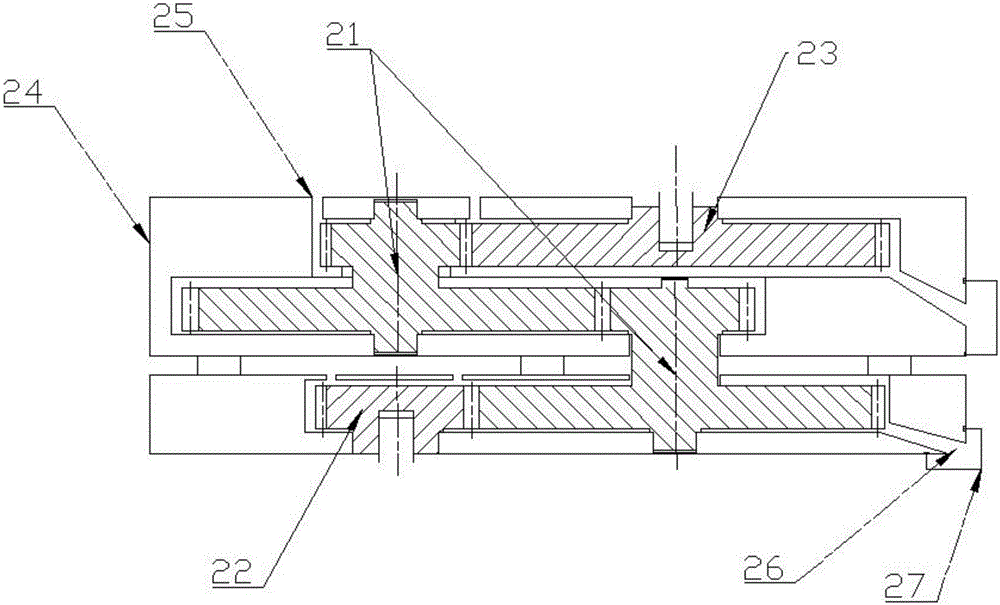

[0046] This embodiment adopts the device described in Embodiment 1 and the mixing tank for implementation. The difference is that the gear set includes a reduction gear 21, and the output gear 22 is in transmission connection with the input gear 23 through the reduction gear 21. The input gear 23 is in transmission connection with the motor through the input shaft. The reduction gear can effectively increase the torque at the output end, shorten the motor response time, and promote uniform and stable stirring. The motor is a high-speed motor, and the motor speed is higher than 5000RPM;

[0047] Moreover, the box body 24 is divided into upper and lower layers, the input gear 23 is arranged on the upper layer of the box body 24 , and the output gear 22 is arranged on the lower layer of the box body 24 . Each layer of the box body 24 is provided with a smoke outlet 25 , an oil collection hole 26 and an oil box 27 . The multi-layer box body 24 can further promote the space separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com