Preparation and application of magnetic cationic hydrogel-based composite adsorption material

A cationic hydrogel and composite adsorption material technology, which is applied in the direction of adsorption of water/sewage treatment, filtration and separation, water pollutants, etc., can solve the problems of inorganic anions in water that have not been reported, and achieve small secondary pollution and simple recycling and regeneration , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

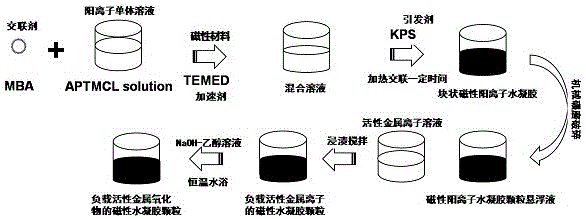

[0042] 1. Weigh 5g of (3-acrylamidopropyl) trimethylammonium chloride (APTMACl) monomer, add 0.5g of cross-linking agent N, N'-methylenebisacrylamide (MBA) to it, and then Add 0.8mL pure water. After the cross-linking agent MBA is completely dissolved, add 0.1ml accelerator N,N,N',N'-tetramethylethylenediamine (TEMED) and 0.5g magnetic γ-Fe 2 o 3 When the above substances are mixed evenly, add 1.5mL saturated potassium persulfate (KPS) solution of initiator. The reaction was stirred for 15 min in a water bath at 60 °C. After the gel was formed, the magnetic hydrogel was transferred to a glass bottle and immersed in pure water for 5 days. Change the water every 8 hours to wash away unreacted substances such as monomers, cross-linking agents, initiators and accelerators. The magnetic hydrogel is then freeze-dried and ground into granules for future use.

[0043] 2. Immerse the cationic hydrogel particles in the mixed solution of saturated lanthanum nitrate and zirconium sulf...

Embodiment example 2

[0046] 1. Weigh 5g of (3-acrylamidopropyl) trimethylammonium chloride (APTMACl) monomer, add 0.5g of cross-linking agent N, N'-methylenebisacrylamide (MBA) to it, and then Add 0.8mL pure water. After the cross-linking agent MBA is completely dissolved, add 0.1ml accelerator N,N,N',N'-tetramethylethylenediamine (TEMED) and 0.5g magnetic γ-Fe 2 o 3 When the above substances are mixed evenly, add 1.5mL saturated potassium persulfate (KPS) solution of initiator. The reaction was stirred for 15 min in a water bath at 60 °C. After the gel was formed, the magnetic hydrogel was transferred to a glass bottle and immersed in pure water for 5 days. Change the water every 8 hours to wash away unreacted substances such as monomers, cross-linking agents, initiators and accelerators. The magnetic hydrogel is then freeze-dried and ground into granules for future use.

[0047] 2. Immerse the cationic hydrogel particles in the saturated lanthanum nitrate and zirconium sulfate solution, the ...

Embodiment example 3

[0050] 1. Weigh 5g of (3-acrylamidopropyl) trimethylammonium chloride (APTMACl) monomer, add 0.5g of cross-linking agent N, N'-methylenebisacrylamide (MBA) to it, and then Add 0.8mL pure water. After the cross-linking agent MBA is completely dissolved, add 0.1ml accelerator N,N,N',N'-tetramethylethylenediamine (TEMED) and 0.5g magnetic γ-Fe 2 o 3 When the above substances are mixed evenly, add 1.5mL saturated potassium persulfate (KPS) solution of initiator. The reaction was stirred for 15 min in a water bath at 60 °C. After the gel was formed, the magnetic hydrogel was transferred to a glass bottle and immersed in pure water for 5 days. Change the water every 8 hours to wash away unreacted substances such as monomers, cross-linking agents, initiators and accelerators. The magnetic hydrogel is then freeze-dried and ground into granules for future use.

[0051] 2. Immerse the hydrogel particles in a mixed solution of lanthanum nitrate-ethanol (every 100ml contains 20g of la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com