Compound heavy metal adsorbent and preparation method thereof

An adsorbent and heavy metal technology, applied in the field of composite heavy metal adsorbent and its preparation, can solve the problems of limited adsorption capacity, influence adsorption efficiency, etc., and achieve the effects of reducing sensitivity, improving adsorption performance, and facilitating recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

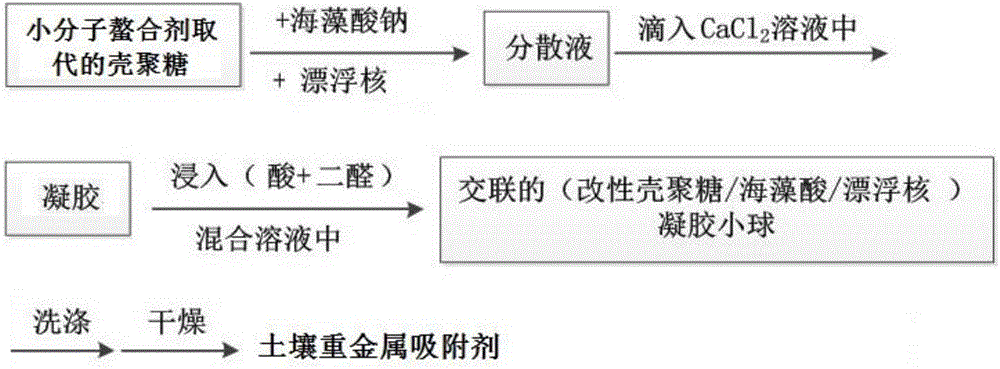

[0041] According to another aspect of the present invention, also provide the preparation method of above-mentioned heavy metal adsorbent, such as figure 1 shown, including the following steps:

[0042] (1) Evenly disperse the floating core in the solution of the composite polymer to obtain a dispersion, so that the mass ratio of the floating core and the composite polymer in the dispersion is (1~5):1; the composite polymer includes Modified chitosan and sodium alginate with a mass ratio of 5:1 to 1:5, the modified group of the modified chitosan is a small molecule chelating agent, and the shell substituted by the small molecule chelating agent The proportion of amino groups of polysaccharides is more than 30%;

[0043] Then the dispersion can be stirred at 20°C-40°C for 3h-8h, and ultrasonically treated for 20min-40min to accelerate the removal of air bubbles in the reaction solution;

[0044] (2) Drop the dispersion liquid into 0.045M~0.9M Ca 2+ solution, and soaked for 3...

Embodiment 1

[0055] (0) Preparation of raw materials

[0056] (0-1) Activation of floating core: according to the ratio of solid-liquid ratio (w / w) of 1:200, the average density is 0.30mg / cm 3 , The hollow glass microspheres with an average particle size of 40 μm are dispersed in distilled water, after stirring for 3 hours, the water-soluble impurities adsorbed on the surface of the hollow glass microspheres are cleaned, and the hollow glass microspheres that can float on the water surface are screened out. , dry at 50°C for later use; disperse the screened hollow glass microspheres into 0.1M HCl aqueous solution and stir for 10 hours, then rinse the acid-treated hollow glass microspheres with distilled water until the distilled water flowing out of washing is close to neutral, and then dry them at 50°C Obtain activated hollow glass microspheres;

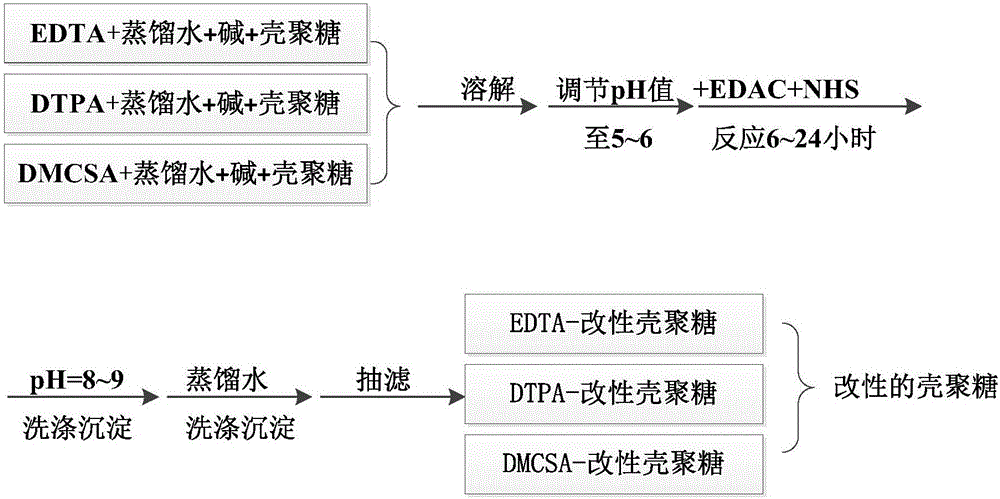

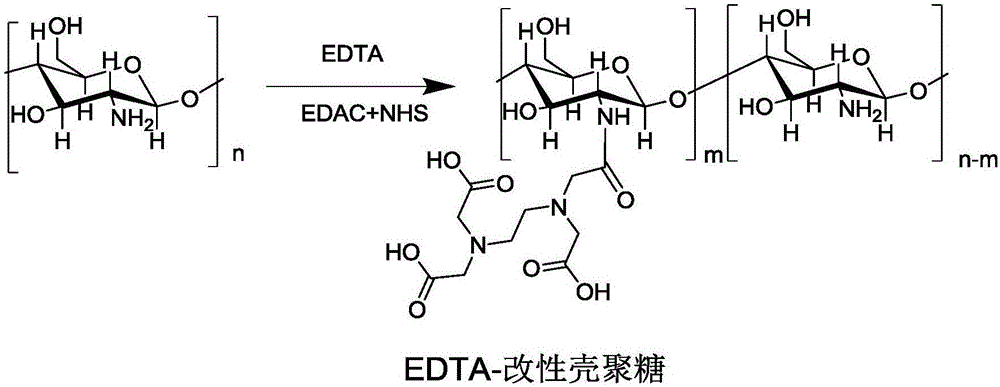

[0057] (0-2) Preparation of EDTA-modified chitosan: First, disperse a certain amount of EDTA solid powder in distilled water, and control the ...

Embodiment 2

[0073] (0) Preparation of raw materials

[0074] (0-1) Activation of floating core: according to the ratio of solid-liquid ratio (w / w) of 1:200, the average density is 0.45mg / cm 3 1. Fly ash floating beads with an average particle size of 105 μm are dispersed in distilled water. After stirring for 3 hours, the water-soluble impurities adsorbed on the surface of the fly ash floating beads are cleaned, and the powdered coal that can float on the water is screened out. Ash floating beads, dry at 50°C for later use; disperse the screened fly ash floating beads into 2% dilute nitric acid solution and stir for 3 hours, then rinse the acid-treated fly ash floating beads with distilled water until the distilled water flowing out of the washing is close to neutral , dried at 50°C for later use;

[0075] (0-2) Preparation of DTPA-modified chitosan: Weigh a certain amount of DTPA solid powder and disperse it in distilled water, add a small amount of sodium hydroxide solid in batches, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com