Detachable combined tool cathode and electrolysis milling method thereof

A tool cathode, combined technology, applied in the field of electrolytic grinding compound machining, can solve the problems of tool damage, time-consuming, limited application scope, etc., to improve stray corrosion, prevent electrolyte leakage, and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific drawings.

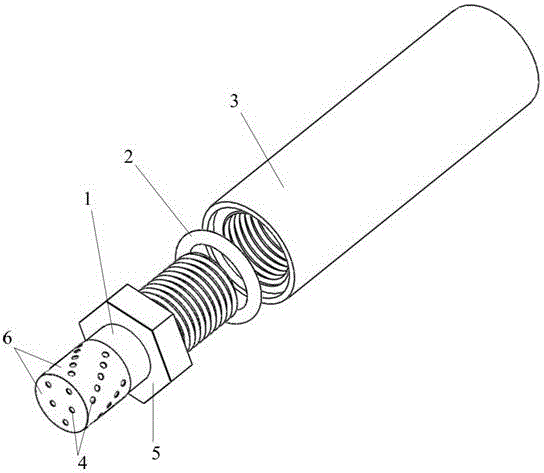

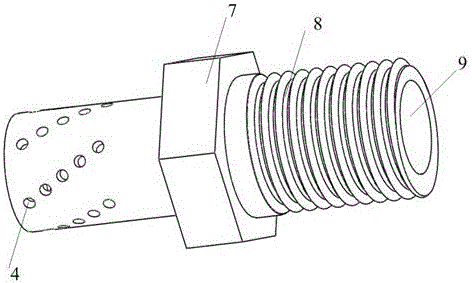

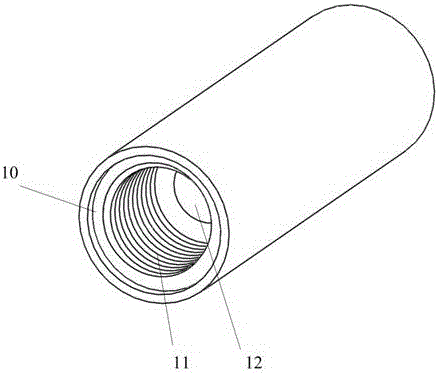

[0024] like Figure 1~3 As shown, a detachable combined tool cathode includes a grinding head 1, a sealing ring 2 and a tool holder 3. The grinding head is a cylindrical structure with a hexagonal flange 7. The lower side wall and bottom surface of the grinding head 1 are provided with a liquid outlet 4 communicating with the central blind hole 9, and an abrasive layer is electroplated. 6. The upper side wall of the grinding head 1 is provided with a positioning external thread 8, the lower end surface of the hexagonal flange 7 of the grinding head 1 is coated with an insulating layer 5, and the cutter bar 3 is a hollow cylindrical structure , the inside is provided with notch groove 10, threaded hole 11, through hole 12 successively, and the material of described cutter bar 3 is the stainless steel material that resists electrolyte corrosion, and the installation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com