Solder for welding of ceramic and metal and welding method

A technology of metal welding and welding method, which is applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems such as the need to improve the bonding strength, complicated operation, inconvenient control, etc., achieve high bonding strength, simple method, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A solder used for ceramic and metal welding, which is a bismuth-based glass frit, which contains components and their mass percentages are: Bi 2 o 3 70%, B 2 o 3 15%, ZnO 12%, and the rest are trace elements; the trace elements include SiO 2 、TiO 2 , MgO, and their mass percentages are 1%, 1%, and 1% respectively.

[0032] The brazing filler metal that is used for ceramics and metal welding adopts the following steps to prepare paste brazing filler metal:

[0033] First, the bismuth-based glass frit is ground into a powder with a particle size of 20 μm, and then an organic binder mixture is prepared with a mixture of ethyl cellulose and terpineol in a mass ratio of 1:3, and the bismuth-based glass frit is mixed with The mixing mass ratio of the mixture of ethyl cellulose and terpineol is 7:3 to make bismuth-containing glass paste.

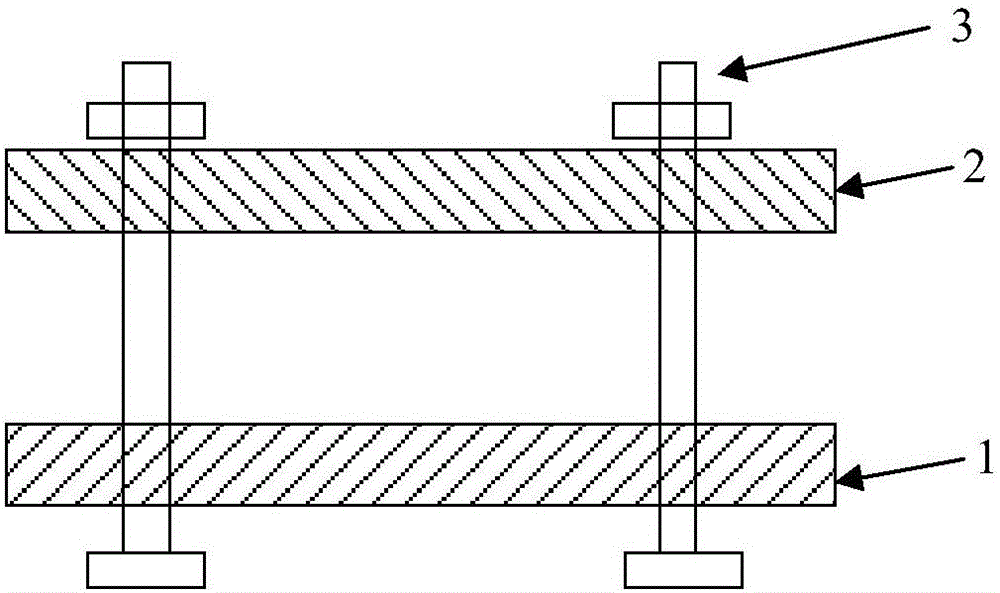

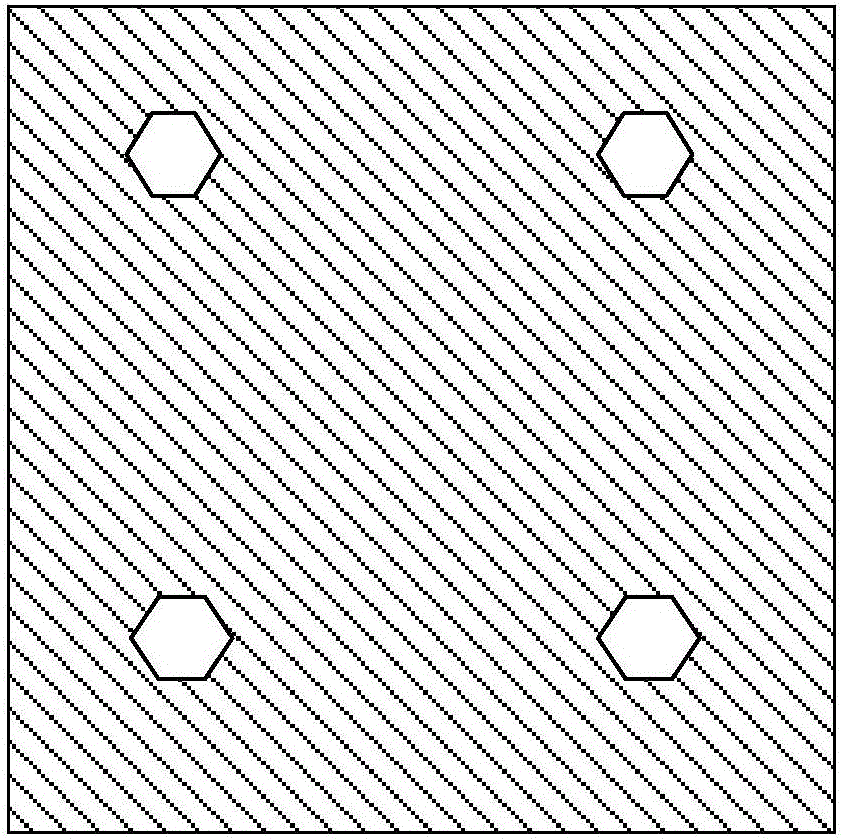

[0034] The prepared bismuth-containing glass paste is used as welding raw material, and pure copper sheet and alumina ceramics are ...

Embodiment 2

[0038] (1) The structure in Example 1 was selected as the raw material matrix, and the alumina ceramics were replaced with aluminum nitride ceramics to make samples.

[0039] (2) The sample preparation method is similar to that in Example 1, the reflux temperature is 850°C, nitrogen gas is passed through during the reflux process, and the sample is cooled with the furnace.

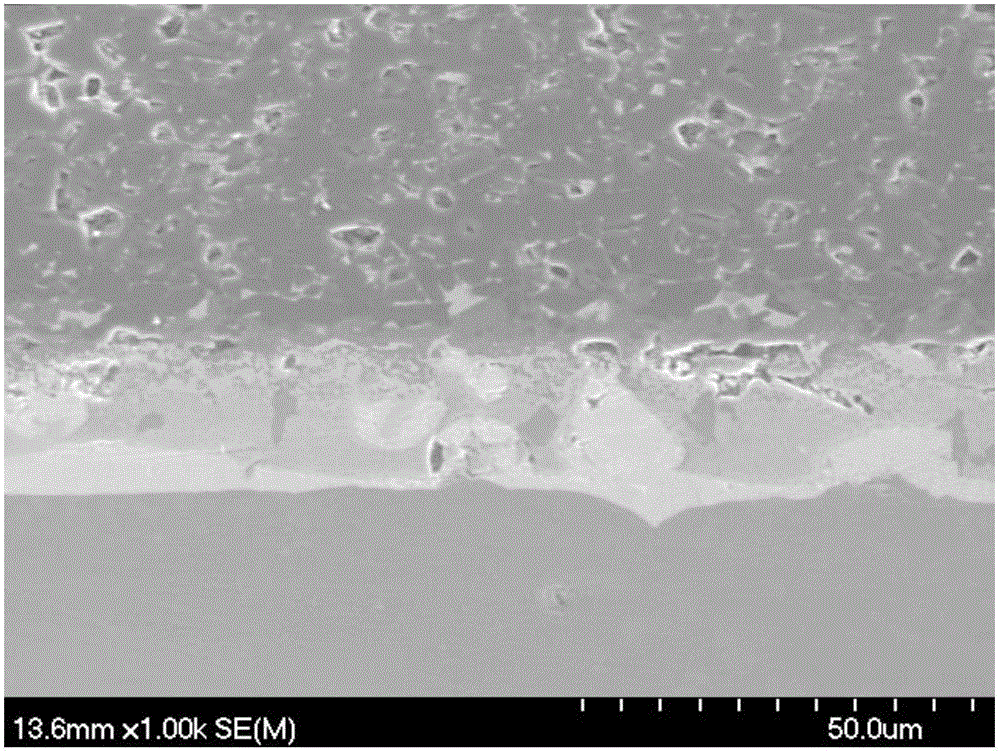

[0040] The prepared samples were observed by scanning electron microscope, as Figure 5 As shown, a dense structure is formed, and the tensile strength of the structure can reach 10MPa after tensile test, which shows that this method can effectively connect aluminum nitride ceramics and copper.

Embodiment 3

[0042]On the basis of Example 1, the components contained in the bismuth-based glass frit and their mass percentages are: Bi 2 o 3 80%, B 2 o 3 7%, ZnO 9%, and the rest are trace elements; the trace elements include SiO 2 、TiO 2 , MgO, and their mass percentages are 1%, 1%, and 2% respectively. The preparation method of the solder used for ceramic and metal welding is the same as in Example 1.

[0043] The brazing material obtained above for welding ceramics and metals was used for the connection of copper sheet and aluminum nitride ceramics. After tensile test, the tensile strength of the structure was 8.2 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap