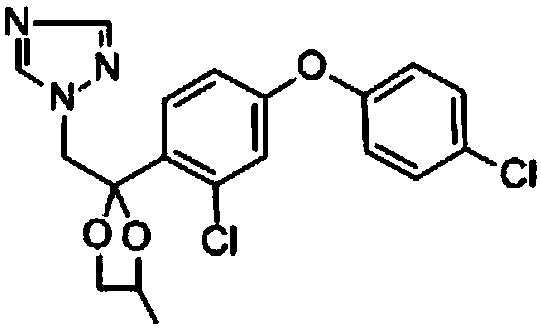

Method for producing high-purity potassium nitrate from potassium-containing waste liquid produced by synthetic fungicide difenoconazole

A technology of difenoconazole and bactericide is applied in the field of producing high-purity potassium nitrate from potassium-containing waste liquid, which can solve the problems of long treatment period, high operating cost, complicated procedures, etc., and achieves excellent quality, low treatment cost and economical efficiency. Significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

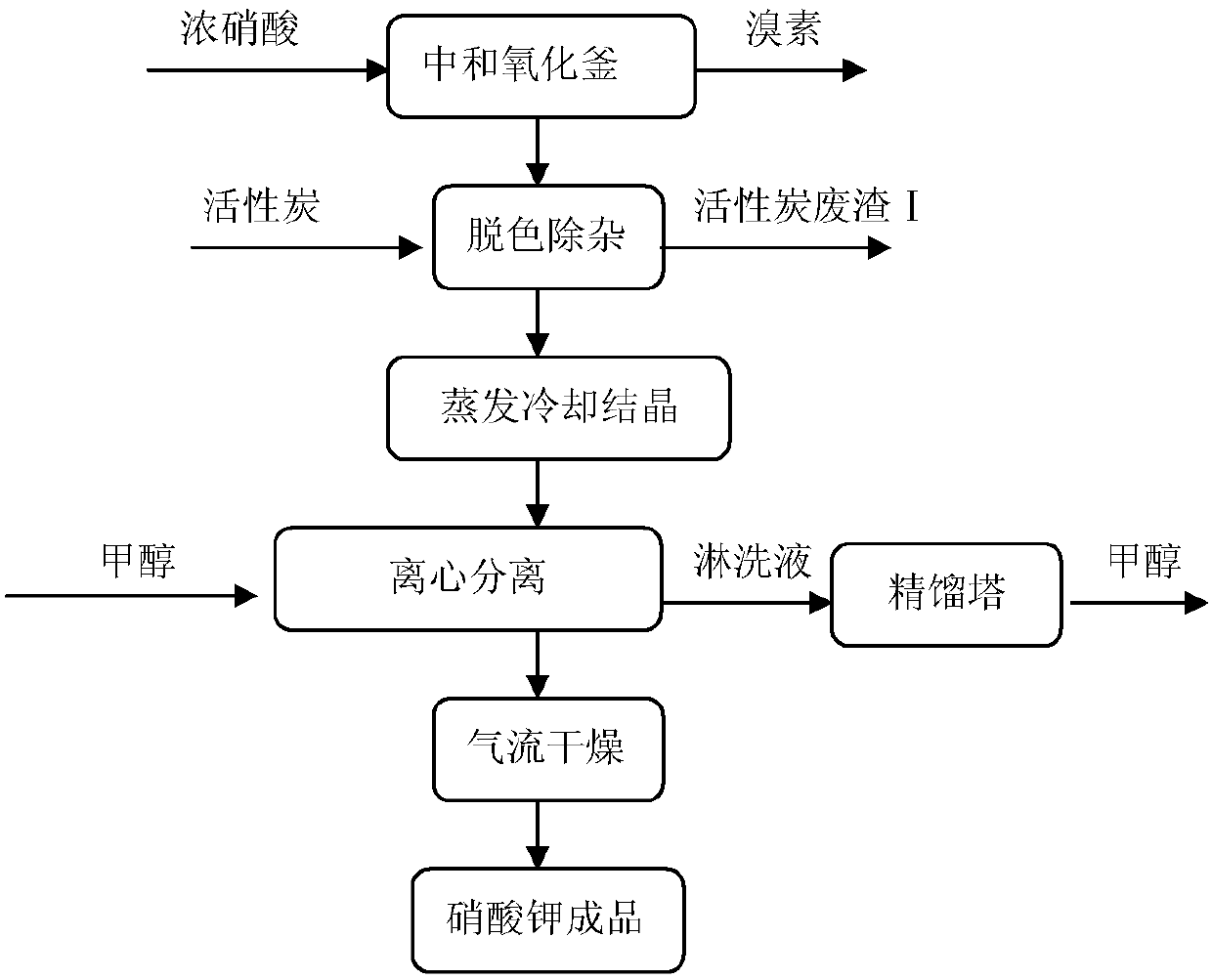

Method used

Image

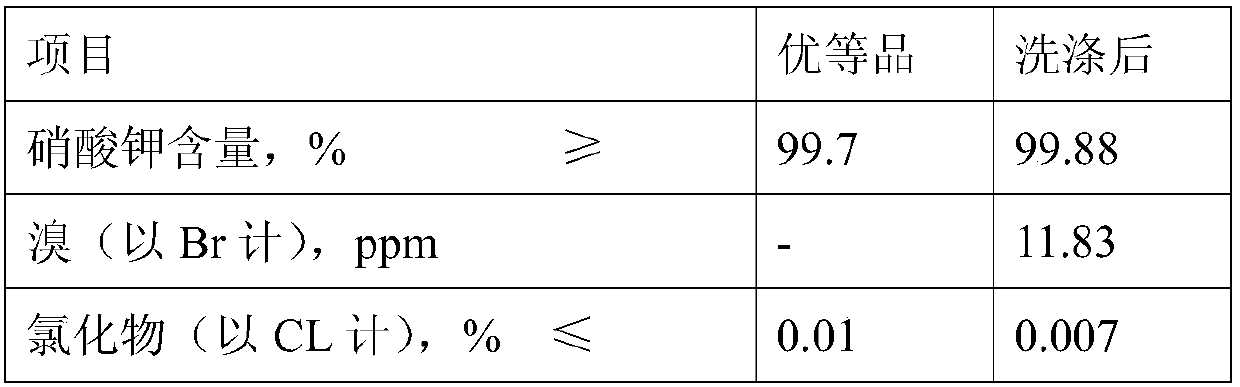

Examples

Embodiment 1-1

[0054] Embodiment 1-1, a method for producing high-purity potassium nitrate from the potassium-containing waste liquid produced by the synthetic fungicide difenoconazole, the following steps are carried out in sequence:

[0055] 1), 5000 liters of potassium-containing waste liquid I produced by the synthetic fungicide difenoconazole (wherein the concentration of potassium nitrate is 250 grams / liter, potassium carbonate 50 grams / liter, potassium bromide 18 grams / liter, other organic impurities Unknown) into the neutralization oxidation kettle, add 65% concentrated nitric acid to neutralize until it is strongly acidic, consume about 420 kilograms of concentrated nitric acid, and get 5200 liters of potassium-containing waste liquid II after neutralization, with a pH of 1.6.

[0056] 2), add concentrated nitric acid in batches (5 batches) to the obtained 5200 liters of potassium-containing waste liquid II neutralized in step 1) for oxidation, add 50 kg of concentrated nitric acid f...

Embodiment 1-2

[0070] Embodiment 1-2, change "1200 liters of water" in step 3) of embodiment 1-1 to "centrifuge the mother liquor obtained in step 5) of embodiment 1-1, step 8) the obtained activated carbon waste residue I washing liquid and step 9) Organic solvent eluent distillation raffinate mixture is 2000 liters in total "; All the other are equal to embodiment 1-1.

[0071] details as follows:

[0072] 1), 5000 liters of potassium-containing waste liquid I produced by the synthetic fungicide difenoconazole (wherein the concentration of potassium nitrate is 250 grams / liter, potassium carbonate 50 grams / liter, potassium bromide 18 grams / liter, other organic impurities Unknown), put into the neutralizing oxidation kettle, add 65% concentrated nitric acid to neutralize, until it is strongly acidic, consume about 420 kilograms of concentrated nitric acid altogether, get 5200 liters of potassium-containing waste liquid II after neutralization, pH is 1.6.

[0073] 2), add concentrated nitric...

Embodiment 2

[0087] Embodiment 2, a method for producing high-purity potassium nitrate from the potassium-containing waste liquid produced by the synthetic bactericide difenoconazole comprises the following steps:

[0088] 1), 5000 liters of potassium-containing waste liquid I produced by the synthetic fungicide difenoconazole (wherein the concentration of potassium nitrate is 250 grams / liter, potassium carbonate 50 grams / liter, potassium bromide 18 grams / liter, other organic impurities Unknown), put into the neutralizing oxidation kettle, add 65% concentrated nitric acid to neutralize, until it is strongly acidic, consume about 420 kilograms of concentrated nitric acid altogether, get 5200 liters of potassium-containing waste liquid II after neutralization, pH is 1.6.

[0089] 2), add concentrated nitric acid in batches to the obtained 5200 liters of potassium-containing waste liquid II in step 1) for oxidation, add 100 kg of concentrated nitric acid for the first time, and naturally heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com