Treatment method of high-salinity high-concentration organic wastewater

A technology of organic wastewater and treatment methods, which is applied in water/sewage treatment, special compound water treatment, heating water/sewage treatment, etc., can solve the problems that cannot realize the treatment of organic pollutants, and achieve increased biodegradability and reaction temperature High, long contact time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

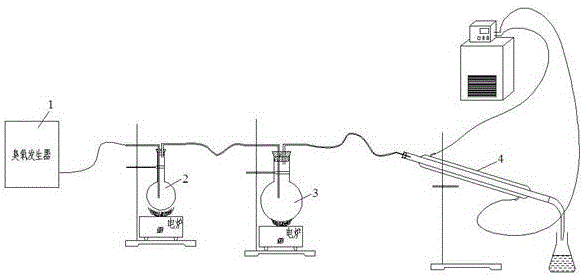

[0024] A method for treating high-salt and high-concentration organic wastewater, the specific steps are:

[0025] (1) Add high-salt and high-concentration organic wastewater into the evaporation kettle 2, and pass ozone into the evaporation kettle 2 through the ozone generator 1 when the organic wastewater starts to be heated and evaporated;

[0026] (2) The steam generated after the organic wastewater is heated and boiled is mixed with ozone, the mixed gas enters the reaction device 3 through the pipeline for reaction or the mixed gas reacts directly in the pipeline, and the sufficient reaction time of the mixed gas is ensured by adding the reaction device 3 or extending the pipeline In order to fully react the ozone with the volatile organic compounds in the steam;

[0027] (3) The fully reacted mixed gas enters the condensing device 4 for condensation, and the formed condensed water is directly discharged;

[0028] (4) After the organic waste water in the evaporator 2 is ...

Embodiment 2

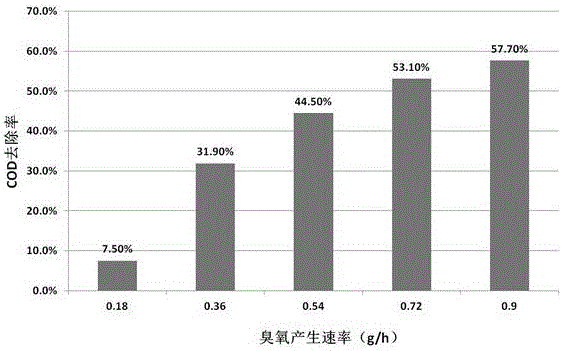

[0030] The mass fraction of NaCl in the organic wastewater is 3%, the initial pH is 7.0, the concentration of methanol is 4g / L, and the concentration of the surfactant sodium dodecylsulfonate is 0.7g / L. The COD value of the organic wastewater reaches 7000mg / L. Evaporation and The ozone passing time was set as 40min, the volume of the reaction device was 500mL, and the condensation temperature was 0°C. figure 2 Shown is the degradation curve of high-salt and high-concentration organic wastewater containing methanol and surfactants under different ozone production rates at the same evaporation time. It can be seen from the figure that as the ozone production rate increases, the corresponding COD value of the condensate obtained continues to increase. reduce.

Embodiment 3

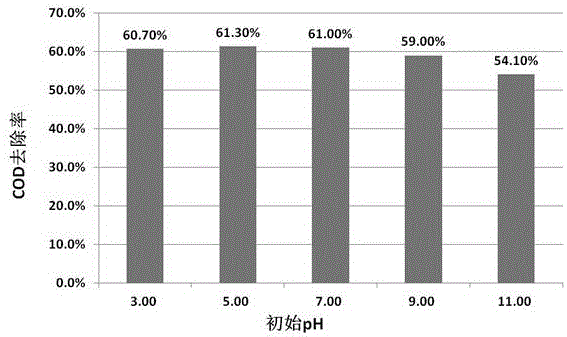

[0032] The mass fraction of NaCl in the organic wastewater is 3%, the ozone generation rate is 0.9g / h, the concentration of methanol is 4g / L, the concentration of the surfactant sodium dodecylsulfonate is 0.7g / L, and the COD value of the organic wastewater reaches 7000mg / L, the evaporation and ozone passing time is set to 40min, the volume of the reaction device is 500mL, and the condensation temperature is 0°C. image 3 Shown is the degradation curve of high-salt and high-concentration organic wastewater containing methanol and surfactants at different initial pHs. The data in the figure shows that the pH of organic wastewater has no obvious effect on the removal rate of COD. When the pH of organic wastewater is greater than 7.0, the condensed water COD degradation rate decreased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com