Erythritol continuous solventing-out membrane crystallization method

An erythritol and crystallization technology, which is applied in the field of erythritol continuous dissolution membrane crystallization, can solve the problem that the dissolution agent does not realize the recovery cycle, the supersaturation of the addition point of the dissolution agent is large, and the consumption of the dissolution agent is large. problems, to achieve the effect of avoiding excessive nucleation, avoiding high supersaturation, and uniform distribution of membrane pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

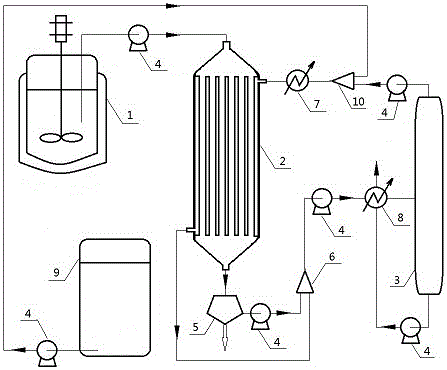

[0023] A method for erythritol continuous dissolution film crystallization, such as figure 1 Shown, specifically comprise crystallization mother liquor tank (1), membrane assembly (2), atmospheric distillation column (3), filter (5), mixer (6), heat exchanger (7), heat exchanger ( 8), eluting agent storage tank (9), mixer (10), between described crystallization mother liquor tank (1) and membrane module (2) tube side inlet, eluting agent storage tank (9) and mixer ( 10), between the top of the atmospheric distillation column (3) and the mixer (10), between the bottom of the atmospheric distillation column (3) and the shell side inlet of the heat exchanger (8), the filter ( 5) between the mixer (6) and between the mixer (6) and the tube side inlet of the heat exchanger (8) are respectively connected by a pipeline provided with a pump (4), and the mixer (10) is connected to the heat exchanger Between the inlet of the tube side of the device (7), between the outlet of the tube s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com