Method for preparing soapnut saponin by two-step method

A technology of sapindus sapindis and one-step method, applied in the field of two-step preparation of sapindus sapinis, can solve the problems of few practical application research, lack of detection methods for total sapindus saponins, etc., and achieve the effect of simple operation and rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

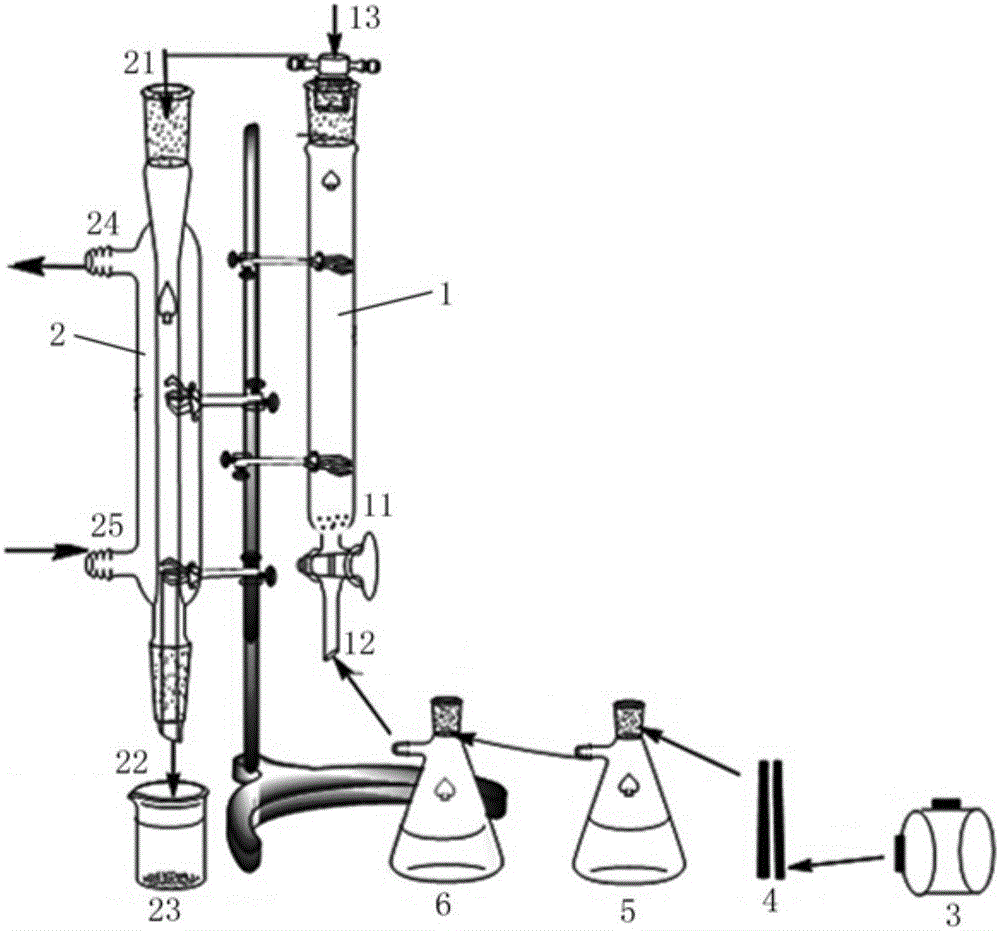

[0022] 1) Macroporous resin adsorption separation (primary macroporous resin separation)

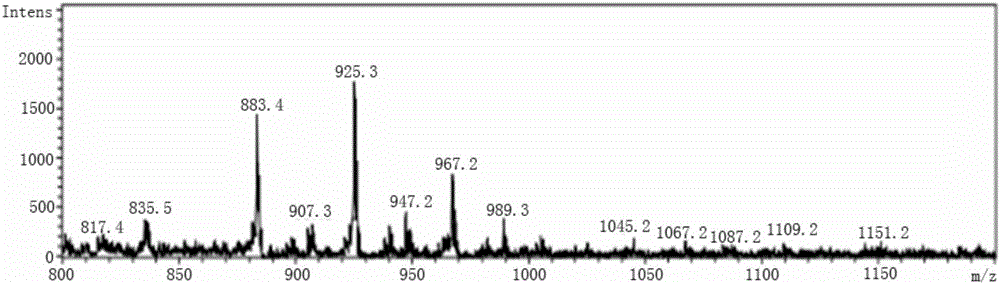

[0023] Sapindus fruit peel is used as raw material, crushed, extracted with alcohol for 2 to 3 times, combined with sapinsia extract, and spray-dried to obtain sapinsia saponin coarse powder. Accurately weigh 0.5001g of sample powder, dilute to 100ml with deionized water, ultrasonically for 15min, put on D101 resin column, wash with 300ml of deionized water to remove sugar, wash with 100ml of 20% alcohol to remove other impurities, wash with 100ml of 70% alcohol to collect saponins, Rotary evaporation, after evaporation of solvent, received saponin coarse powder. The 70% alcohol wash can be used twice, and 0.5ml and 0.1ml of the two 70% alcohol washes are used to measure the absorbance values of saponins and total sugars respectively with a UV spectrophotometer, and substitute them into the respective relational formulas:

[0024] The relational formula between absorbance value (A) an...

Embodiment 2

[0037] 1) Macroporous resin adsorption separation (twice macroporous resin separation)

[0038] Sapindus fruit peel is used as raw material, crushed, extracted with alcohol for 2 to 3 times, combined with sapinsia extract, and spray-dried to obtain sapinsia saponin coarse powder. Accurately weigh 1.0g of sample powder, dilute to 250ml with deionized water, ultrasonically for 15min, put on D101 resin column, wash with 300ml of deionized water to remove sugar, wash with 100ml of 20% alcohol to remove other impurities, wash with 100ml of 70% alcohol to collect saponins, Rotary evaporation, after evaporating the solvent, the acetone settled, centrifuged, evaporating the acetone, adding deionized water to dissolve, and extracting with saturated water n-butanol three times, taking the organic layer and evaporating the solvent, and preparing a 20 mg / mL aqueous solution of sapindus saponin, Apply D101 macroporous resin at a speed of 1mL / min, wash with 3BV of deionized water and elute ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com