High-strength cellulose/polyvinyl alcohol compound hydrogel, and preparation and application thereof

A technology of composite hydrogel and polyvinyl alcohol, which is applied in the field of hydrogel and its preparation and application, can solve the problems such as no reports of homogeneous cellulose and polyvinyl alcohol blended hydrogel, and achieve excellent mechanical properties, Good biocompatibility and environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

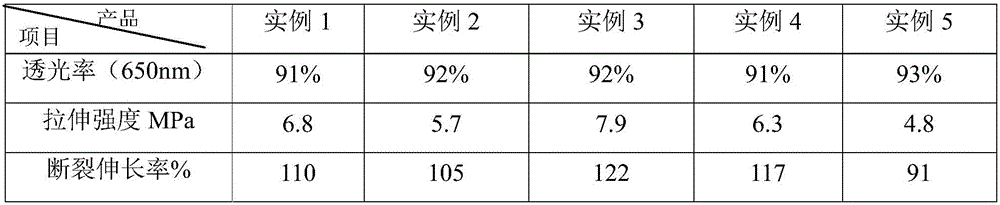

Examples

Embodiment 1

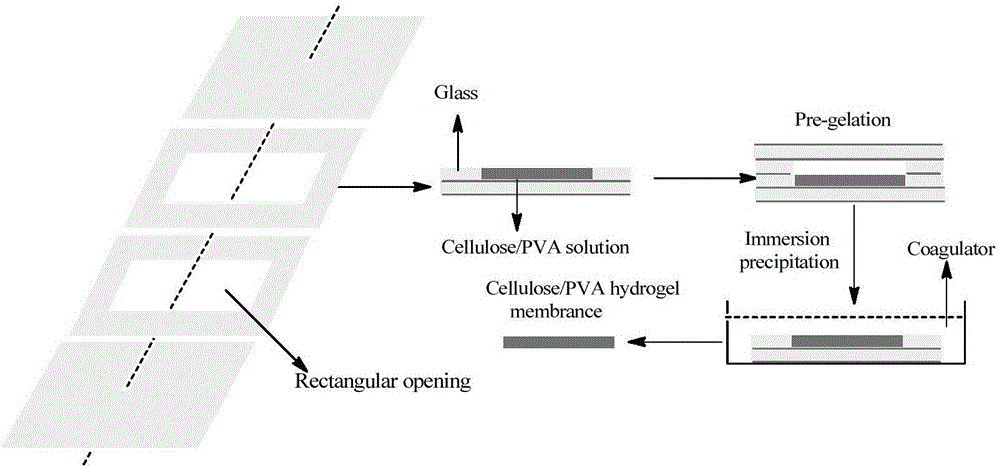

[0029] Put 3g cellulose, polymerization degree 550, 50g 1-butyl-3-methylimidazole acetate, and 3g polyvinyl alcohol 1750, 50g 1-butyl-3-methylimidazole acetate into jacket oil In a reaction vessel with a stirrer in a bath heating device, and vacuumize, then heat while stirring, raise the temperature to 90-95°C, and keep the temperature until the cellulose and polyvinyl alcohol are completely dissolved;

[0030] Mix the above 20g cellulose solution and 20g polyvinyl alcohol solution, and stir for 180min; then inject the resulting mixed solution into a specific sealed combination mold, and pre-gel at -20°C for 24 hours; The glue is immersed in water at 5°C, the solvent is replaced, and the solvent is soaked and rinsed repeatedly to ensure that the solvent is completely precipitated to obtain a cellulose / polyvinyl alcohol composite hydrogel film.

[0031] The prepared hydrogel film was further cross-linked and crystallized at -20°C, and the final prepared hydrogel film was cut in...

Embodiment 2

[0033] Put 2g cellulose, polymerization degree 550, 50g 1-butyl-3-methylimidazole acetate, and 2g polyvinyl alcohol 1750, 50g 1-butyl-3-methylimidazole acetate respectively into the jacket oil In a reaction vessel with a stirrer in a bath heating device, and vacuumize, then heat while stirring, raise the temperature to 90-95°C, and keep the temperature until the cellulose and polyvinyl alcohol are completely dissolved;

[0034] Mix the above 20g cellulose solution and 20g polyvinyl alcohol solution, and stir for 180min; then inject the resulting mixed solution into a specific sealed combination mold, and pre-gel at 5°C for 24 hours; the pre-gelled gel Immerse in water at 5°C, replace the solvent, and repeatedly soak and rinse to ensure that the solvent is completely precipitated to prepare a cellulose / polyvinyl alcohol composite hydrogel film.

[0035] The prepared hydrogel film was further cross-linked and crystallized at -5°C, and the final prepared hydrogel film was cut int...

Embodiment 3

[0037] Put 3g cellulose, polymerization degree 1100, 50g 1-butyl-3-methylimidazole acetate, and 3g polyvinyl alcohol 1750, 50g 1-butyl-3-methylimidazole acetate respectively into the jacket oil In a reaction vessel with a stirrer in a bath heating device, and vacuumize, then heat while stirring, raise the temperature to 90-95°C, and keep the temperature until the cellulose and polyvinyl alcohol are completely dissolved;

[0038] Mix the above 20g cellulose solution and 20g polyvinyl alcohol solution, and stir for 180min; then inject the resulting mixed solution into a specific sealed combination mold, and pre-gel at -20°C for 24 hours; The glue is immersed in water at 5°C, the solvent is replaced, and the solvent is soaked and rinsed repeatedly to ensure that the solvent is completely precipitated to obtain a cellulose / polyvinyl alcohol composite hydrogel film.

[0039] The prepared hydrogel film was further cross-linked and crystallized at -20°C, and the final prepared hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com