Solvent type strippable plastic film antirust agent and preparation method thereof

A plastic film and solvent-based technology, which is applied in the field of solvent-based peelable plastic film antirust agent and its preparation, can solve the problems of difficult removal and achieve good antirust effect, convenient removal, and the effect of inhibiting oxygen absorption corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

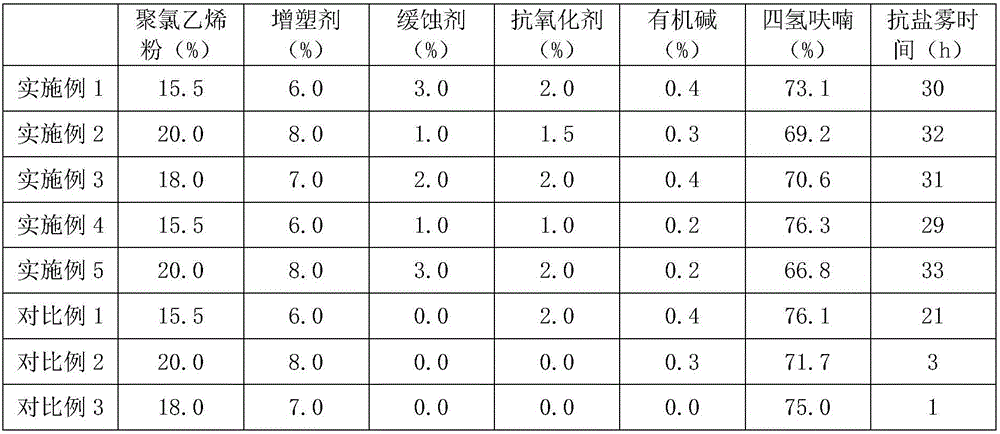

[0031] Embodiment 1: A kind of solvent-type peelable antirust agent for plastic film comprises the following components: polyvinyl chloride powder, plasticizer, corrosion inhibitor, antioxidant, organic base and tetrahydrofuran, by weight percentage, component content As in Table 1 below. The corrosion inhibitor is barium petroleum sulfonate, the organic base is benzotriazole, the antioxidant is tert-butyl p-cresol, and the plasticizer is dibutyl phthalate.

[0032] The preparation method of the solvent-based peelable plastic film antirust agent is as follows: step A, weigh the corrosion inhibitor and tetrahydrofuran according to the formula, heat and melt the corrosion inhibitor and add it to tetrahydrofuran to obtain a mixed solution a; step B, according to the formula Measure and weigh polyvinyl chloride powder and plasticizer, add to mixed solution a, stir evenly to obtain mixed solution b; step C, weigh organic base and antioxidant according to the formula, add to mixed s...

Embodiment 2

[0033]Embodiment 2: A kind of solvent-type peelable antirust agent for plastic film comprises the following components: polyvinyl chloride powder, plasticizer, corrosion inhibitor, antioxidant, organic base and tetrahydrofuran, by weight percentage, component content As in Table 1 below. Among them, the corrosion inhibitor is barium dinonylnaphthalene sulfonate, the organic base is benzotriazole, the antioxidant is tert-butyl p-cresol, and the plasticizer is bis(2-ethylhexyl) phthalate. , Dioctyl phthalate, Di-n-octyl phthalate, Butyl benzyl phthalate, Butyl benzyl phthalate, Dicyclohexyl phthalate, Diisobutyl phthalate One of esters, dimethyl phthalate, diethyl phthalate, diisononyl phthalate, and diisodecyl phthalate.

[0034] The preparation method of the solvent-based peelable plastic film antirust agent is as follows: step A, weigh the corrosion inhibitor and tetrahydrofuran according to the formula, heat and melt the corrosion inhibitor and add it to tetrahydrofuran to ...

Embodiment 3

[0035] Embodiment 3: A kind of solvent-type peelable antirust agent for plastic film comprises the following components: polyvinyl chloride powder, plasticizer, corrosion inhibitor, antioxidant, organic base and tetrahydrofuran, by weight percentage, component content As in Table 1 below. The corrosion inhibitor is barium petroleum sulfonate, the organic base is benzotriazole, the antioxidant is tert-butyl p-cresol, and the plasticizer is dibutyl phthalate.

[0036] The preparation method of the solvent-based peelable plastic film antirust agent is as follows: step A, weigh the corrosion inhibitor and tetrahydrofuran according to the formula, heat and melt the corrosion inhibitor and add it to tetrahydrofuran to obtain a mixed solution a; step B, according to the formula Measure and weigh polyvinyl chloride powder and plasticizer, add to mixed solution a, stir evenly to obtain mixed solution b; step C, weigh organic base and antioxidant according to the formula, add to mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com