Turbulent electrodeposition method and matching device and modular expansion scheme

A turbulent flow and electrochemical technology, applied in the field of electrodeposition, can solve problems such as concentration polarization, and achieve the effects of high DC efficiency, reduced manufacturing and maintenance costs, and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

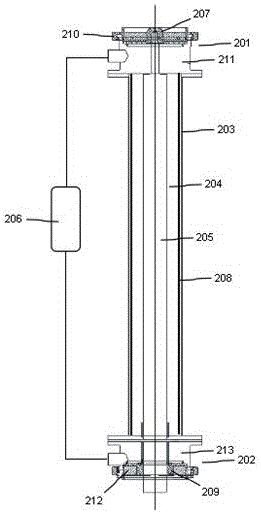

[0034] This example: as figure 1 As shown, a turbulent electrowinning method includes turbulent surging of an electrolyte solution containing target metal ions during electrochemical deposition of an electrolyte solution.

[0035] During the electrochemical deposition process of the electrolytic solution containing the target metal ions in the confined space of the cathode and anode, the electrolytic solution is turbulently surging by the circulating pump. surging, eliminating the phenomenon of concentration polarization caused by the electrodeposition reaction rate being greater than the ion diffusion reaction rate.

[0036] The electrolyte solution is turbulently driven by the circulating pump 206 .

[0037] The electrochemical deposition process of the electrolyte solution containing the target metal ions includes the electrochemical deposition process of the electrolyte solution containing the target metal ions in the confined space of the cathode and anode.

[0038] lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com