Method for detecting content of corrosive chlorine in phosphate fire-resistant oil

A detection method and fuel-resistant technology, which is applied in the direction of measuring devices, test sample preparation, instruments, etc., can solve the problems of inability to distinguish and detect corrosive chlorine separately, lack of pertinence, etc., and achieve breakthroughs in technical limitations and a wide range of applications , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

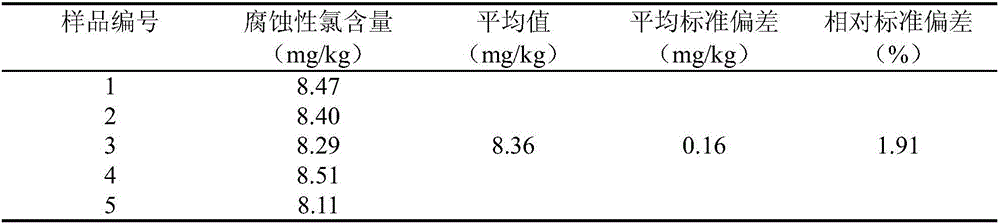

[0048] Formulated with 0.1% HNO 3 Add 50 mL of the aqueous solution into a high-temperature, high-pressure and corrosion-resistant polytetrafluoroethylene autoclave, stir and heat up to 100°C, keep it constant for 12 hours, and cool to room temperature as a blank control group. Formulated with 0.1% HNO 3 Take 50mL of aqueous solution, weigh 1g of phosphate ester anti-fuel oil and add it into a high-temperature, high-pressure and corrosion-resistant polytetrafluoroethylene autoclave, stir and raise the temperature to 100°C, keep it constant for 2h, and after cooling to room temperature, obtain a phosphate ester anti-fuel oil sample and a decomposition test. The mixed solution after the liquid reaction is completed. Pour the mixed solution into a centrifuge tube and centrifuge at a speed of 1000rad / min for 30 minutes to separate the phosphate ester fuel oil sample and the decomposition test solution. The corrosive chlorine in the phosphate ester fuel oil sample enters the aqueo...

Embodiment 2

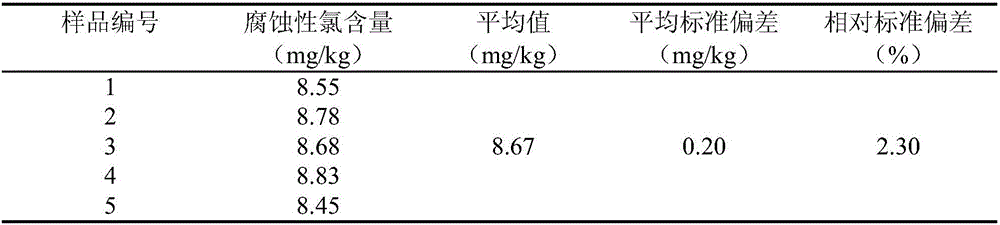

[0053] Take 30 mL of deionized water and add it into a high-temperature, high-pressure and corrosion-resistant polytetrafluoroethylene autoclave, stir and heat up to 85°C, keep it constant for 24h, and cool to room temperature as a blank control group. Take 30mL of deionized water, weigh 1g of phosphate ester anti-fuel oil and add it to a high-temperature, high-pressure and corrosion-resistant PTFE autoclave, stir and raise the temperature to 85°C, keep it constant for 24h, and obtain a phosphate ester anti-fuel sample after cooling to room temperature The mixed solution after the reaction with the decomposition test solution is completed. Pour the mixed solution into a centrifuge tube and centrifuge at a speed of 3000rad / min for 10min to separate the phosphate ester fuel oil sample and the decomposition test solution. Measurement. Then use ion chromatography to analyze the chlorine content C of the decomposition test solution in the blank control group 0 and the chlorine co...

Embodiment 3

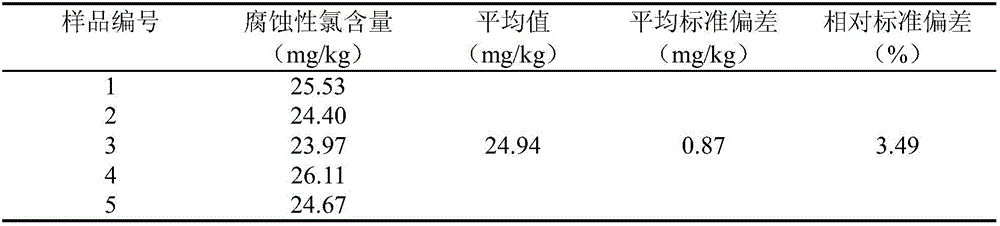

[0058] 1) Prepare 0.5% H 2 SO 4 Add 20 mL of the aqueous solution into a high-temperature, high-pressure and corrosion-resistant polytetrafluoroethylene autoclave, stir and raise the temperature to 50°C, keep it constant for 8 hours, and use it as a blank control group after cooling to room temperature.

[0059] 2) Prepare 0.5% H 2 SO 4 Take 20mL of aqueous solution, weigh 1g of phosphate ester anti-fuel oil and add it into a high-temperature, high-pressure and corrosion-resistant polytetrafluoroethylene autoclave, stir and raise the temperature to 50°C, keep it constant for 8h, and obtain a phosphate ester anti-fuel oil sample and decomposition test after cooling to room temperature. The mixed solution after the liquid reaction is completed. Pour the mixed solution into a centrifuge tube and centrifuge at a speed of 10,000 rad / min for 5 minutes to separate the phosphate ester fuel oil sample and the decomposition test solution. The corrosive chlorine in the phosphate ester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com