Permanent magnet direct driving type explosion-proof variable frequency adjustable-speed motor combined type driving system

A variable frequency speed regulating motor, permanent magnet direct drive technology, applied in the direction of electric components, magnetic circuit rotating parts, and control/drive circuit connection, can solve the problem of reducing the performance of permanent magnet synchronous motors, raw materials are not reproducible, The electromagnetic disturbance of the surrounding system is large, so as to weaken the demagnetization effect, facilitate large-scale promotion and application, and reduce the effect of electromagnetic disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

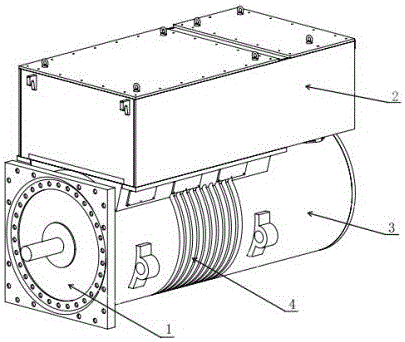

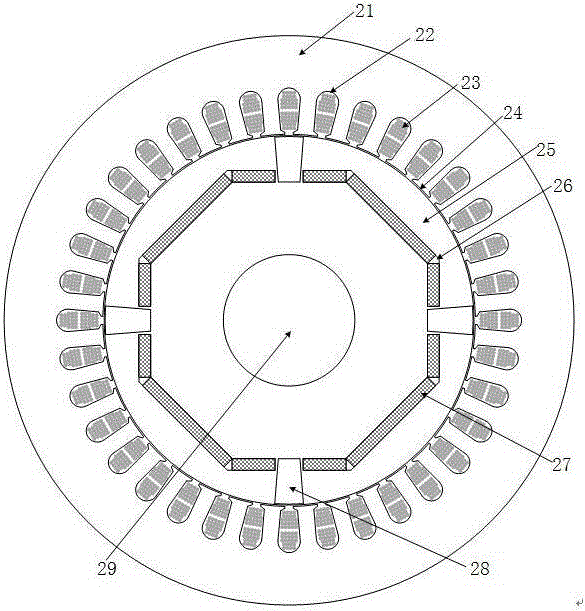

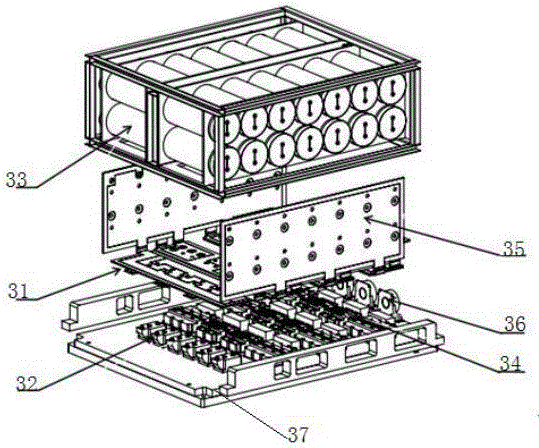

[0025] Embodiment 1: see figure 1 , figure 2 , a permanent magnet direct drive type explosion-proof frequency conversion motor combined drive system, the drive system includes a permanent magnet direct drive motor 1, a frequency converter 2, an explosion-proof casing 3 and a water-cooled pipeline composition 4, the frequency converter 2, The motor 1 is arranged up and down, the water-cooling pipeline is dispersed in the explosion-proof casing, the water circuit is connected in series as a whole, the frequency converter part includes a power part and a control part; the permanent magnet direct drive motor includes a rotating shaft 29, a rotor core 25, Ferrite permanent magnet 27, stator winding 23, stator iron core 21 and housing base, the rotor iron core 25 passes through the rotating shaft in the form of stacked punching sheets, permanent magnet installation grooves are evenly distributed in the rotor iron core, the The ferrite permanent magnet is glued in the permanent mag...

Embodiment 2

[0026] Example 2: see figure 2 , as an improvement of the present invention, wherein the even number of magnetic poles in the permanent magnet installation groove, the permanent magnets of each pole are arranged in an isosceles trapezoid without sealing, and there is an isosceles trapezoidal wind tunnel between each pole, that is, an air magnetic barrier 28. The isosceles trapezoidal wind tunnel is symmetrically distributed on the quadrature axis of the rotor rotating coordinate system. The side of the isosceles trapezoid close to the rotating shaft is the upper bottom, and the side close to the stator is the lower bottom, and the lower bottom and the air gap Not connected. This design ensures the structural rigidity of the rotor on the basis of ensuring the ventilation. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0027] Embodiment 3: see figure 2 , as an improvement of the present invention, the height of the air magnetic barrier 28 is greater than the width of the permanent magnet installation groove 26, and the upper bottom of the air magnetic barrier 28 does not exceed the permanent magnet installation groove. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com