Nickel-based catalyst and method for preparing hydrogen from bio-oil

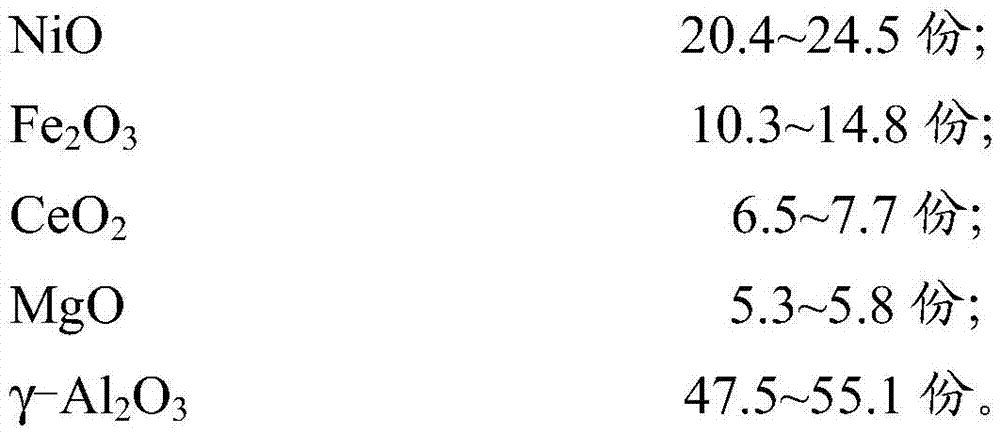

A nickel-based catalyst and bio-oil technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of low hydrogen concentration and yield, high reaction temperature, and difficult hydrogen purification etc. to achieve the effects of reducing energy consumption, improving purity and lowering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In the method for preparing hydrogen provided by the present invention, bio-oil and water are first mixed and reacted in the presence of the nickel-based catalyst. Wherein, the bio-oil is produced by rapid cracking of biomass, and its main components are oxygen-containing organic matter and water. In an embodiment provided by the present invention, the main constituent elements of the oxygen-containing organic matter in the bio-oil are C, H and O, wherein, the content of C in the oxygen-containing organic matter is 35-45 wt%, and the content of H in the The content of the oxygen-containing organic matter is 5-10 wt%, and the content of O in the oxygen-containing organic matter is 45-55 wt%. In another embodiment provided by the present invention, the main content of the oxygen-containing organic matter in the bio-oil is The constituent elements are C, H and O, wherein the content of C in the oxygen-containing organic matter is 39.92-41.71 wt%, the content of H in the ox...

Embodiment 1

[0071] Preparation of Nickel-Based Catalysts

[0072] Weigh commercially available 79.41g nickel nitrate (molecular formula: Ni(NO 3 ) 2 ·6H 2 O, purity: analytically pure AR), 15.43g ferric nitrate (molecular formula: Fe(NO 3 ) 3 9H 2 O, purity: analytically pure AR), 16.40g cerium nitrate (molecular formula: Ce(NO 3 ) 2 ·6H 2 O, purity: analytically pure AR) and 36.85g magnesium nitrate (molecular formula: Mg(NO 3 ) 2 ·6H 2 O, purity: analytically pure AR), add 500mL deionized water, configure nitrate mixed solution; then commercially available 55.0gγ-Al 2 o 3 Molecular sieve powder (Pingxiang Zhongtian Chemical Filling Co., Ltd., model KA405) was added to the above nitrate solution, stirred for 5 hours, and then left to stand for 24 hours after impregnation; Dry in an oven at 120°C for 12 hours; finally use a muffle furnace to bake at 550°C and an air atmosphere for 8 hours to obtain a mixed oxide catalyst precursor containing nickel, iron, cerium, magnesium and...

Embodiment 2

[0075] Preparation of Nickel-Based Catalysts

[0076] Weigh commercially available 95.38g nickel nitrate (molecular formula: Ni(NO 3 ) 2 ·6H 2O, purity: analytically pure AR), 18.72g ferric nitrate (molecular formula: Fe(NO 3 ) 3 9H 2 O, purity: analytically pure AR), 19.42g cerium nitrate (molecular formula: Ce(NO 3 ) 2 ·6H 2 O, purity: analytically pure AR) and 36.85g magnesium nitrate (molecular formula: Mg(NO 3 ) 2 ·6H 2 O, purity: analytically pure AR); add 600mL deionized water to configure a nitrate mixed solution; then commercially available 47.5gγ-Al 2 o 3 Molecular sieve powder (Pingxiang Zhongtian Chemical Filling Co., Ltd., model KA405) was added to the above nitrate solution, stirred for 5 hours, and then left to stand for 24 hours after impregnation; Dry in an oven at 120°C for 12 hours; finally use a muffle furnace to bake at 550°C and an air atmosphere for 8 hours to obtain a mixed oxide catalyst precursor containing nickel, iron, cerium, magnesium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap