Integrated method for high organic silt high-efficiency dehydration and nutrient soil preparation

A technology of organic matter and nutrient soil, applied in the direction of organic fertilizers, inorganic fertilizers, calcium fertilizers, etc., can solve the problems of difficult dehydration, complicated process, long cycle, etc., and achieve the effects of enhanced dehydration efficiency, rich nutrient elements, and enhanced fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

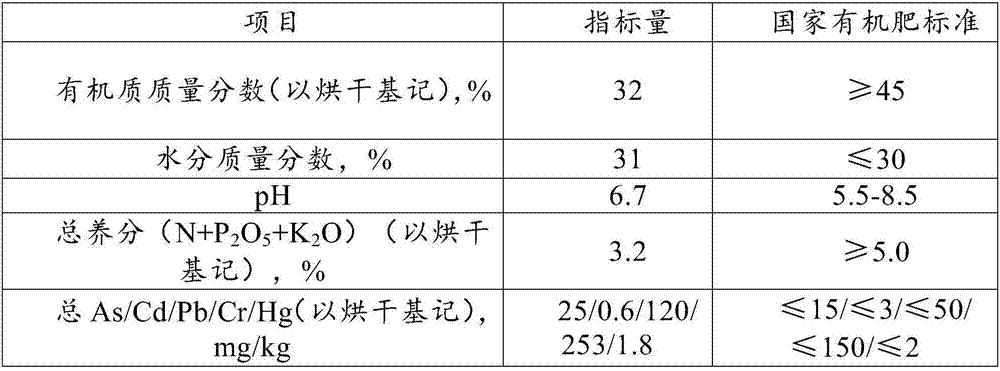

example 1

[0046] After flocculation and sedimentation, the high water content sludge has a solid content of 20% and an organic matter content of 10%. Phosphate rock powder with a mass ratio of 8% is added, and the mud mixer is rapidly stirred for 5 minutes to mix evenly to obtain the first sludge mixture material.

[0047] Add 6% dry crushed straw and 3% furfural slag to the first sludge mixture, stir rapidly for 6 minutes, and mix evenly to obtain the second sludge mixture.

[0048] Add quicklime with a mass ratio of 3% to the second sludge mixture material, stir rapidly for 5 minutes, and mix evenly to obtain a third sludge mixture material.

[0049] The prepared third mud mixture material was added to a plate and frame filter press for dehydration treatment, the filter press time was controlled at 30 minutes, and the water content of the mud cake obtained after dehydration was 33%.

[0050] The low water content mud cake obtained by pressure filtration is mixed with humus with a mass...

example 2

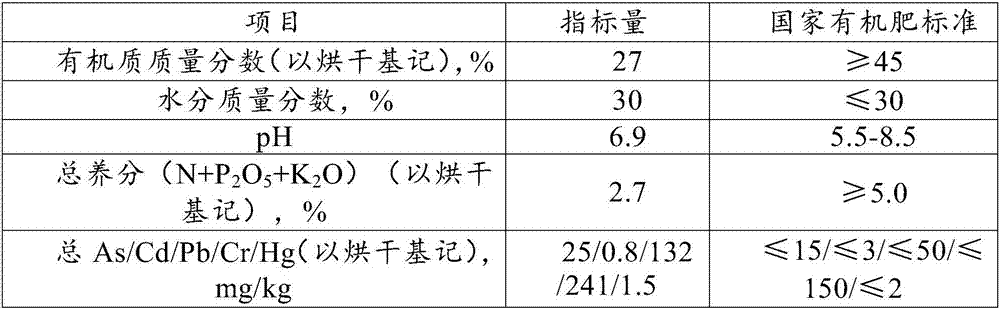

[0054] After flocculation and sedimentation, the high water content sludge has a solid content of 23% and an organic matter content of 12%. Phosphate rock powder with a mass ratio of 9% is added, and the mud mixer is stirred rapidly for 5 minutes to mix evenly to obtain the first sludge mixture material.

[0055] Add 7% dry and pulverized straw and 2% furfural slag to the first sludge mixture, stir rapidly for 7 minutes, and mix evenly to obtain the second sludge mixture.

[0056] Add quicklime with a mass ratio of 2% to the second sludge mixture material, stir rapidly for 5 minutes, and mix evenly to obtain a third sludge mixture material.

[0057] The prepared third mud mixture material was added to a plate and frame filter press for dehydration treatment, the filter press time was controlled at 32 minutes, and the water content of the mud cake obtained after dehydration was 31%.

[0058] The low water content mud cake obtained by pressure filtration is mixed with humus with...

example 3

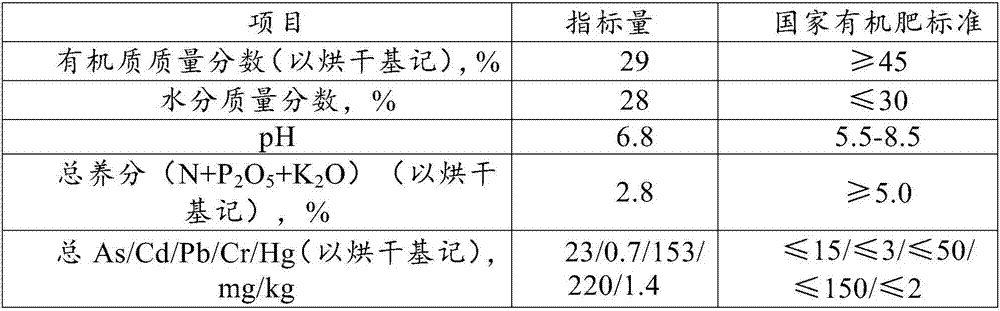

[0062] After flocculation and sedimentation, the high water content sludge has a solid content of 28% and an organic matter content of 11%. Phosphate rock powder with a mass ratio of 10% is added, and the mud mixer is stirred rapidly for 5 minutes to mix evenly to obtain the first sludge mixture material.

[0063] Add 8% dry crushed straw and 2% furfural slag in mass ratio to the first sludge mixture material, stir rapidly for 8 minutes, and mix evenly to obtain the second sludge mixture material.

[0064] Add quicklime with a mass ratio of 1% to the second sludge mixture material, stir rapidly for 5 minutes, and mix evenly to obtain a third sludge mixture material.

[0065] The prepared third mud mixture material is added to a plate and frame filter press for dehydration treatment, the filter press time is controlled at 35 minutes, and the water content of the mud cake obtained after dehydration is 30%.

[0066] The low water content mud cake obtained by pressure filtration i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com