A kind of rubber additive and its preparation and application

An additive and rubber technology, applied in the field of tire rubber additives, can solve problems such as poor adhesive function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

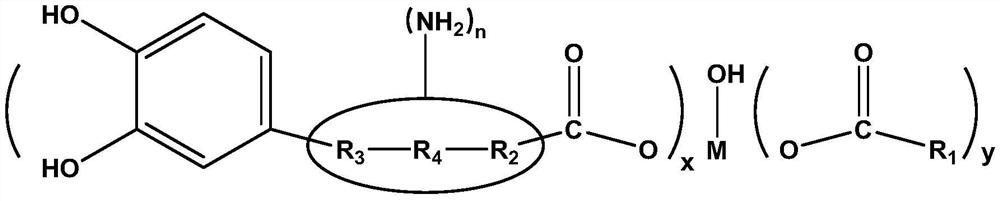

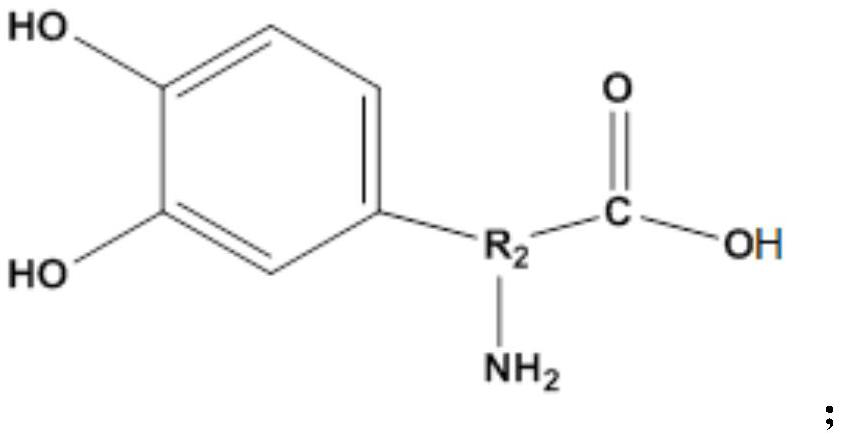

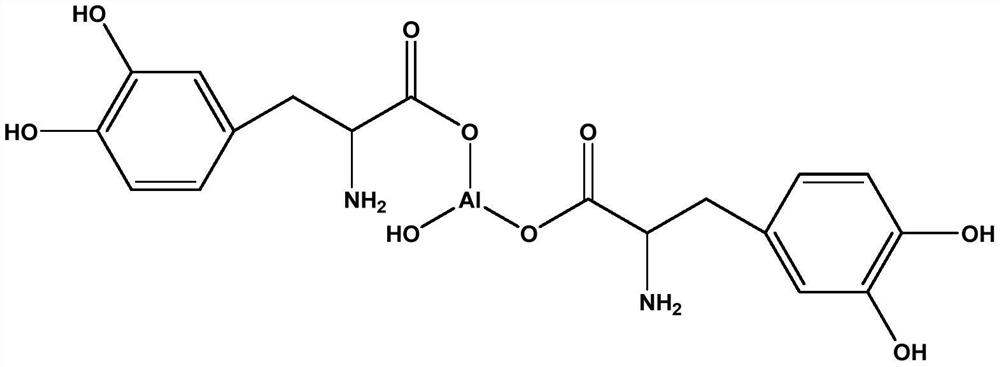

[0042] A kind of rubber additive, its chemical structural formula is:

[0043]

[0044] The preparation method of above-mentioned metallic soap, comprises the following steps:

[0045] (1) Add 1L distilled water and 16g sodium hydroxide solid (purity ≥ 97%, purchased from TCI) in a 2L beaker, after the sodium hydroxide is completely dissolved, add 78.88g levodopa (DOPA) (purity ≥ 99%) %, purchased from Aladdin). The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution A)

[0046] (2) Another 2L beaker was taken, and 1L of distilled water and 94.8g of potassium aluminum sulfate dodecahydrate (purity ≥ 99%, purchased from Aladdin) were added into it. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution B)

[0047] (3) Finally, in the case of vigorously stirring solution A, slowly pour solution B into solution A at a speed of ...

Embodiment 2

[0049] A kind of rubber additive, its chemical structural formula is:

[0050]

[0051] The preparation method of above-mentioned metallic soap, comprises the following steps:

[0052] (1) Add 1 L of distilled water and 8 g of solid sodium hydroxide (purity ≥ 97%, purchased from Aladdin) in a 2 L beaker. After the sodium hydroxide was completely dissolved, 39.4 g of levodopa (DOPA) (purity ≥ 99%, purchased from Aladdin) was added. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution A)

[0053] (2) Add 1 L of distilled water and 8 g of solid sodium hydroxide (purity ≥ 97%, purchased from Aladdin) in a 2 L beaker. After the sodium hydroxide was completely dissolved, 60.1 g of 12-hydroxystearic acid (purity ≥ 90%, purchased from TCI) was added. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution B)

[0054] (3) Another ...

Embodiment 3

[0057] A kind of rubber additive, its chemical structural formula is:

[0058]

[0059] The preparation method of above-mentioned metallic soap, comprises the following steps:

[0060] (1) Add 1 L of distilled water and 8 g of solid sodium hydroxide (purity ≥ 97%, purchased from Aladdin) in a 2 L beaker. After the sodium hydroxide was completely dissolved, 39.4 g of levodopa (DOPA) (purity ≥ 99%, purchased from Aladdin) was added. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution A)

[0061] (2) Add 1 L of distilled water and 8 g of solid sodium hydroxide (purity ≥ 97%, purchased from Aladdin) in a 2 L beaker. After the sodium hydroxide was completely dissolved, 56.9 g of stearic acid (purity ≥ 95%, purchased from Aladdin) was added. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution B)

[0062] (3) Another 2L bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com