Norbornene type compound, and preparation method and application thereof

A norbornene and compound technology, applied in the field of norbornene derivatives, can solve the problems of limited wide application, swelling, poor dimensional stability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

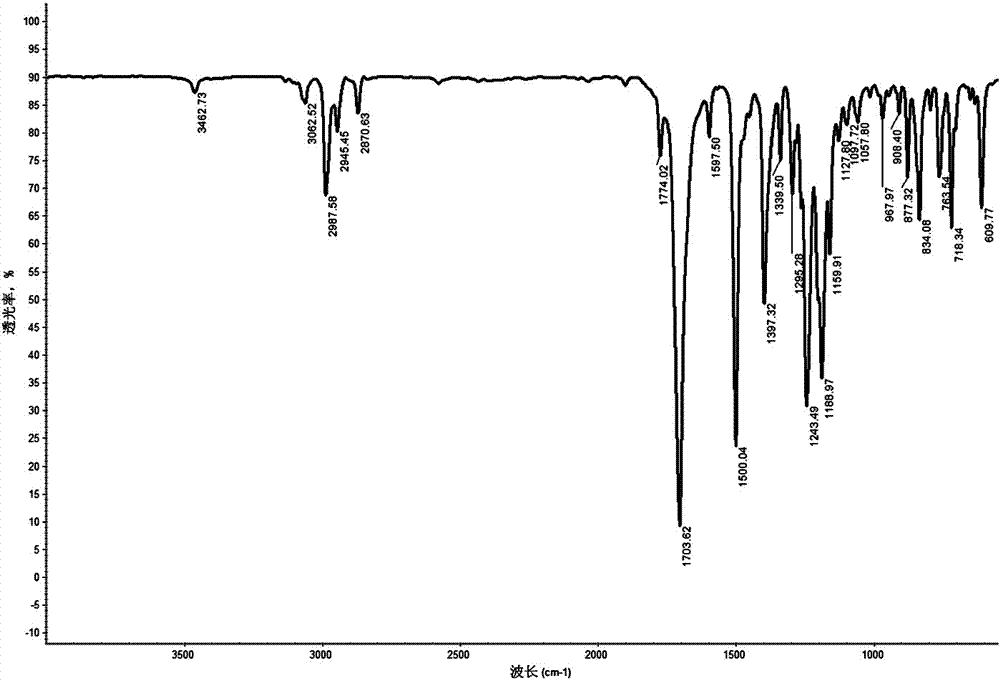

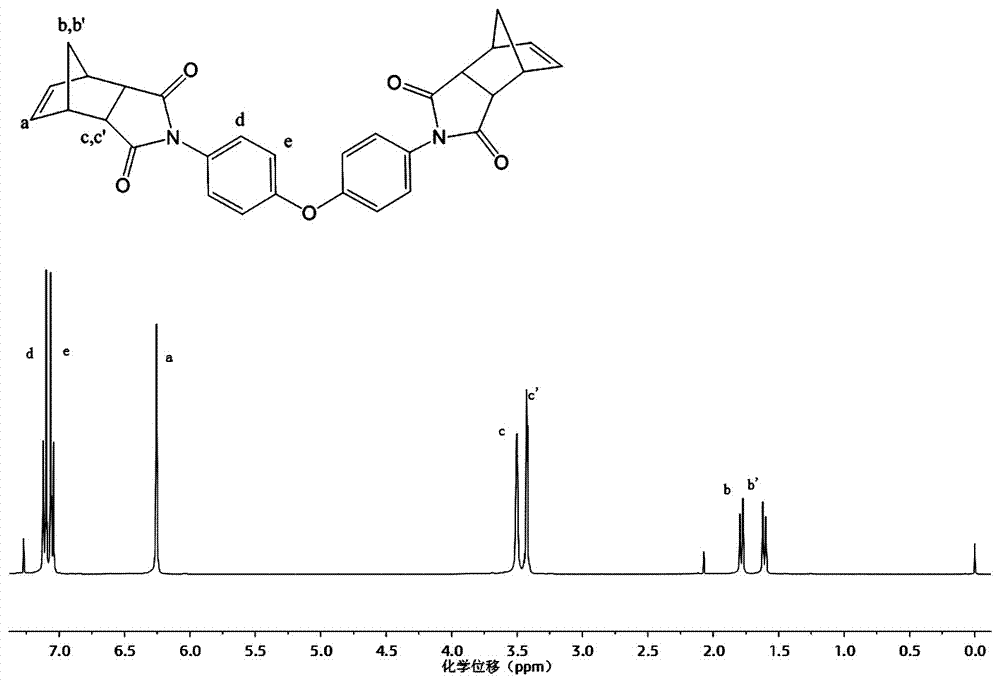

[0038] Add 200g of norbornene diacid anhydride into 500ml of glacial acetic acid, stir and dissolve evenly, raise the temperature to 120°C, slowly add 100g of 4,4'-diaminodiphenyl ether while stirring, condense and heat under reflux for 12h. Deionized water was added to the reaction solution to precipitate a white precipitate, which was filtered by suction and dried in vacuo to obtain 280 g of a crosslinking agent intermediate 4,4'-bis(norbornene-5,6-diamidyl)-p-phenylene ether white powder, Yield 95%.

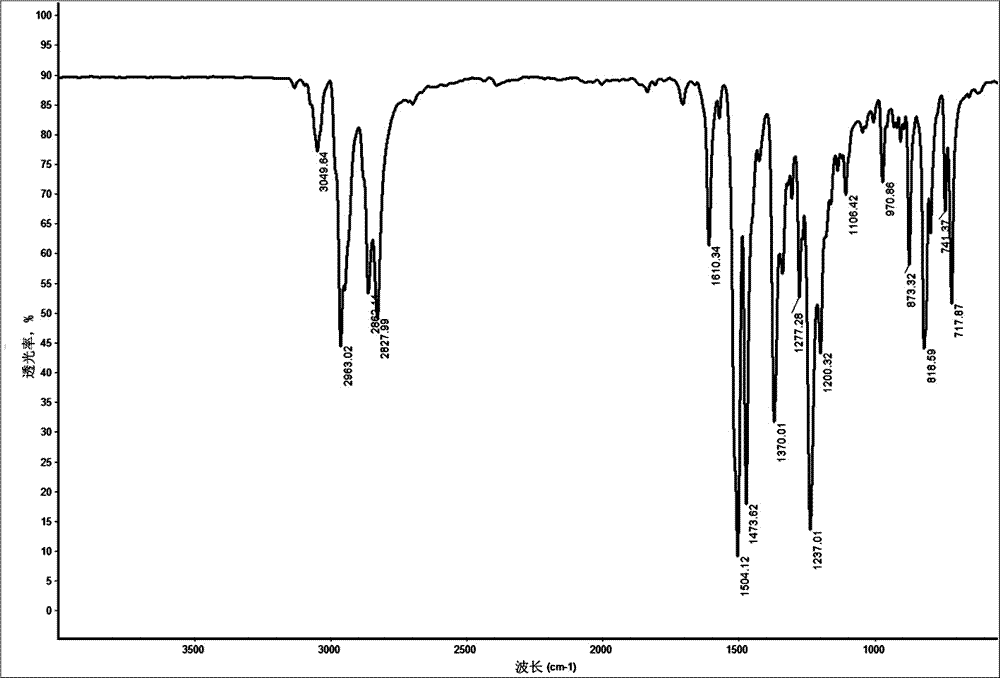

[0039] Add 200g of lithium aluminum tetrahydride to 200ml of ether, stir and mix well. Take 200g of 4,4'-bis(norbornene-5,6-diamido)-p-phenylene ether and dissolve it in 200ml of dichloromethane, and slowly add it dropwise to the ether solution of lithium aluminum hydride mentioned above at 0°C, at room temperature Under reaction 24h. The reaction solution was suction filtered to obtain a colorless solution, added anhydrous magnesium sulfate to dry, suction filtered, and rot...

Embodiment 2

[0041] Add 250g of norbornene diacid anhydride to 500ml of glacial acetic acid, stir and dissolve evenly, raise the temperature to 120°C, slowly add 100g of 4,4'-diaminodiphenyl ether while stirring, condense and heat under reflux for 12h. Deionized water was added to the reaction solution to precipitate a white precipitate, which was filtered by suction and dried in vacuo to obtain 350 g of a crosslinking agent intermediate 4,4'-bis(norbornene-5,6-diamidyl)-p-phenylene ether white powder, Yield 93%.

[0042]Add 200g of lithium aluminum tetrahydride to 200ml of ether, stir and mix well. Take 200g of 4,4'-bis(norbornene-5,6-diamido)-p-phenylene ether and dissolve it in 200ml of dichloromethane, and slowly add it dropwise to the ether solution of lithium aluminum hydride mentioned above at 0°C, at room temperature Under reaction 24h. The reaction solution was filtered with suction to obtain a colorless solution, dried by adding anhydrous magnesium sulfate, filtered with suctio...

Embodiment 3

[0044] Add 300g of norbornene diacid anhydride to 500ml of glacial acetic acid, stir and dissolve evenly, raise the temperature to 120°C, slowly add 100g of 4,4'-diaminodiphenyl ether while stirring, condense and heat under reflux for 12h. Deionized water was added to the reaction solution to precipitate a white precipitate, which was filtered by suction and dried in vacuo to obtain 400 g of a crosslinking agent intermediate 4,4'-bis(norbornene-5,6-diamidyl)-p-phenylene ether white powder, Yield 88%.

[0045] Add 200g of lithium aluminum tetrahydride to 200ml of ether, stir and mix well. Take 250g of 4,4'-bis(norbornene-5,6-diamido)-p-phenylene ether and dissolve it in 200ml of dichloromethane, and slowly add it dropwise to the ether solution of lithium aluminum hydride mentioned above at 0°C, at room temperature Under reaction 24h. The reaction solution was filtered with suction to obtain a colorless solution, dried by adding anhydrous magnesium sulfate, filtered with sucti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com