High-strength corrosion-resistant plastic for septic tank

A high-strength, anti-corrosion technology, applied in the field of high-strength anti-corrosion plastics for septic tanks, can solve the problems of shortened service life, polluted groundwater, unreasonable design, etc., to improve quality, reduce shrinkage, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A high-strength corrosion-resistant plastic for septic tanks is made of the following parts by mass: 62 parts of linear low-density polyethylene, 45 parts of polypropylene, 10 parts of attapulgite, 8 parts of phytic acid, 10 parts of mica flakes, silicon carbonate 4 parts of whiskers, 17 parts of nano calcium carbonate, 10 parts of polyurea, 4 parts of antioxidant, 2 parts of antistatic agent, 3.5 parts of methacryloxypropyltrimethoxysilane, 0.5 part of vinyl acetate.

[0018] The preparation method of high-strength anti-corrosion plastics for septic tank, the preparation steps are as follows:

[0019] 1) Weigh the raw materials according to the weight of the powder, add linear low density polyethylene and polypropylene into the mixer, heat to 45°C, first mix at a speed of 60r / min for 1.5h, and then mix at a speed of 80r / min 2h;

[0020] 2) Then add attapulgite, phytic acid, mica flakes, silicon carbonate whiskers, nano calcium carbonate, polyurea, antioxidant, antista...

Embodiment 2

[0024] A high-strength corrosion-resistant plastic for septic tanks is made of the following parts by mass: 56 parts of linear low-density polyethylene, 60 parts of polypropylene, 12 parts of attapulgite, 7 parts of phytic acid, 14 parts of mica flakes, silicon carbonate 8 parts of whiskers, 20 parts of nano calcium carbonate, 8 parts of polyurea, 3 parts of antioxidant, 3 parts of antistatic agent, 4 parts of methacryloxypropyl trimethoxysilane, 1 part of vinyl acetate.

[0025] The preparation method of high-strength anti-corrosion plastics for septic tank, the preparation steps are as follows:

[0026] During the preparation process, the mixing temperature was 50°C, the preheating temperature in the screw extruder was 140°C, the plasticizing temperature was 178°C, the extrusion temperature was 165°C, and the extrusion speed was 11m / min, and the remaining steps were the same as in Example 1 .

Embodiment 3

[0028] A high-strength corrosion-resistant plastic for septic tanks is made of the following parts by mass: 60 parts of linear low-density polyethylene, 55 parts of polypropylene, 11 parts of attapulgite, 6 parts of phytic acid, 15 parts of mica flakes, silicon carbonate 7 parts of whiskers, 18 parts of nano calcium carbonate, 7 parts of polyurea, 5 parts of antioxidant, 2 parts of antistatic agent, 4.2 parts of methacryloxypropyl trimethoxysilane, 2 parts of vinyl acetate.

[0029] The preparation method of high-strength anti-corrosion plastics for septic tank, the preparation steps are as follows:

[0030] During the preparation process, the mixing temperature was 55°C, the preheating temperature in the screw extruder was 145°C, the plasticizing temperature was 183°C, the extrusion temperature was 155°C, and the extrusion speed was 12m / min, and the remaining steps were the same as in Example 1 .

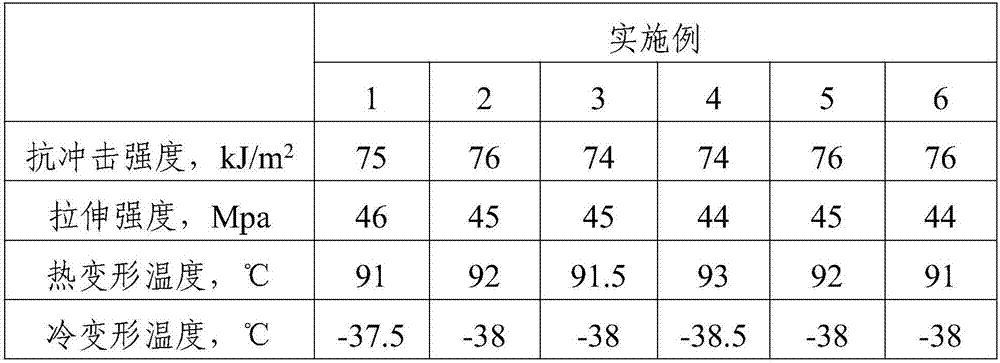

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com