Polyaniline-chopped glass fiber-phenolic resin paint and preparation method thereof

A technology of chopped glass fiber and phenolic resin, applied in the direction of anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve the problems of poor UV light resistance, limited application range, poor impact resistance, etc., and achieve stable thermodynamic and chemical properties , high wear resistance, excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

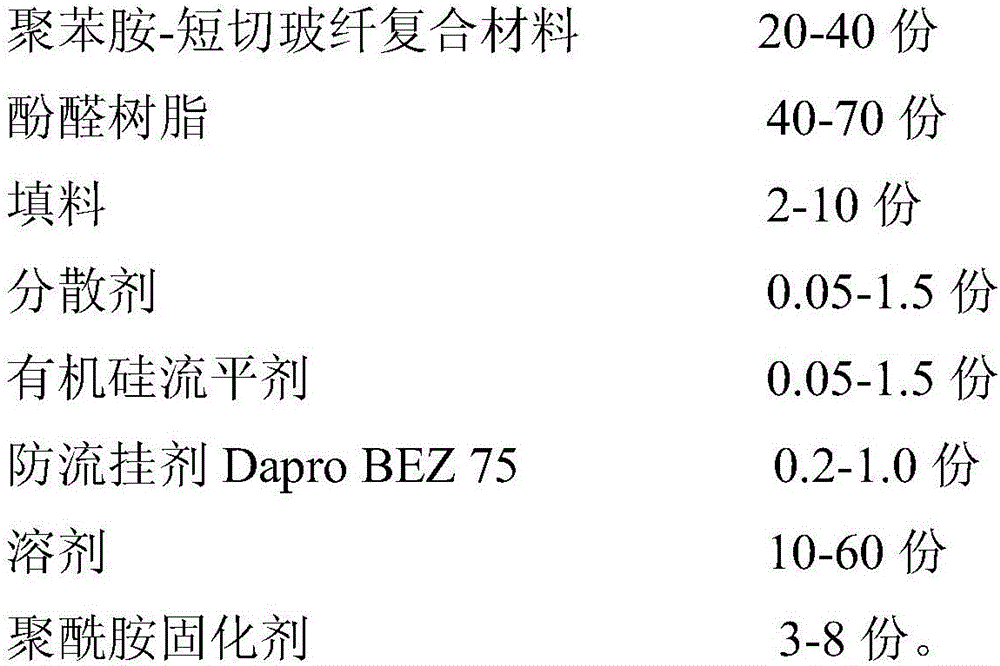

[0029] A polyaniline-chopped glass fiber-phenolic resin coating composed of the following raw materials in parts by mass:

[0030] 22 parts of polyaniline-chopped glass fiber composite, 40 parts of phenolic resin, 5 parts of magnesium silicate, 1 part of LBD-1, 0.5 part of silicone leveling agent, 0.5 part of anti-sagging agent Dapro BEZ 75, 26 parts of solvent , 5 parts of polyamide curing agent.

[0031] The preparation method of the polyaniline-chopped glass fiber-phenolic resin coating includes the following steps:

[0032] 1) Add the polyamide curing agent and phenolic resin to the compound solvents butanol and xylene, with a mass ratio of 1:2; stir for 2h to form a uniform solution 1;

[0033] 2) Add LBD-1, silicone leveling agent, magnesium silicate and anti-sagging agent Dapro BEZ 75 to acetone, stir for 30 minutes to form a uniform solution 2. Under stirring, add polyaniline / chopped glass fiber Add composite material powder and solution 1 to solution 2, stir evenly and let s...

Embodiment 2

[0037] A polyaniline-chopped glass fiber-phenolic resin coating composed of the following raw materials in parts by mass:

[0038] 20 parts of polyaniline-chopped glass fiber composite material, 42 parts of phenolic resin, 3 parts of zinc stearate, 1 part of LBCB-1, 0.5 part of silicone leveling agent, 0.5 part of anti-sagging agent Dapro BEZ 75, solvent 26 Parts, 7 parts of polyamide curing agent.

[0039] The preparation method of the polyaniline-chopped glass fiber-phenolic resin coating includes the following steps:

[0040] 1) Add the polyamide curing agent and phenolic resin to the compound solvents butanol and xylene, with a mass ratio of 1:3; stir for 1.5h to form a uniform solution 1;

[0041] 2) Add LBCB-1, silicone leveling agent, zinc stearate and anti-sagging agent Dapro BEZ75 to acetone, stir for 30 minutes to form a homogeneous solution 2. Under stirring, add polyaniline / chopped glass fiber Add composite material powder and solution 1 to solution 2, stir evenly and let...

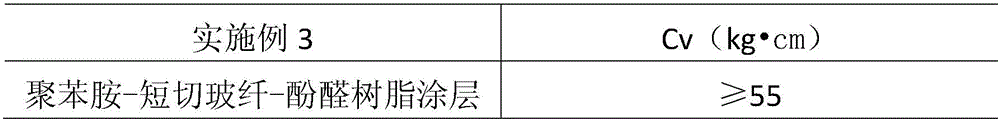

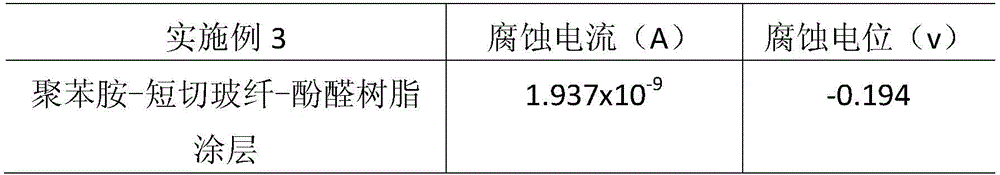

Embodiment 3

[0044] A polyaniline-chopped glass fiber-phenolic resin coating composed of the following raw materials in parts by mass:

[0045] 24 parts of polyaniline-chopped glass fiber composite material, 42 parts of phenolic resin, 2 parts of magnesium silicate, 1 part of LBD-1, 0.5 part of silicone leveling agent, 0.5 part of anti-sagging agent Dapro BEZ 75, 25 parts of solvent , 5 parts of polyamide curing agent.

[0046] The preparation method of the polyaniline-chopped glass fiber-phenolic resin coating includes the following steps:

[0047] 1) Add the polyamide curing agent and phenolic resin to the compound solvents butanol and xylene, with a mass ratio of 1:3; stir for 2h to form a uniform solution 1;

[0048] 2) Add LBD-1, silicone leveling agent, magnesium silicate and anti-sagging agent Dapro BEZ 75 to acetone, stir for 40 minutes to form a homogeneous solution 2. Under stirring, add polyaniline / chopped glass fiber Add the composite material powder and solution 1 to solution 2, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com