Gas appliance burner cap surface enameling process

A technology for fire covers and burning appliances, which is used in manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems of easy corrosion and rust on the surface of burning stoves, coating peeling, etc., to achieve suitable surface roughness, improved sulfuric acid resistance, The effect of high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of enamel on the surface of the fire cover of the burning appliance, the material of the fire cover of the burning appliance is iron; including the following steps:

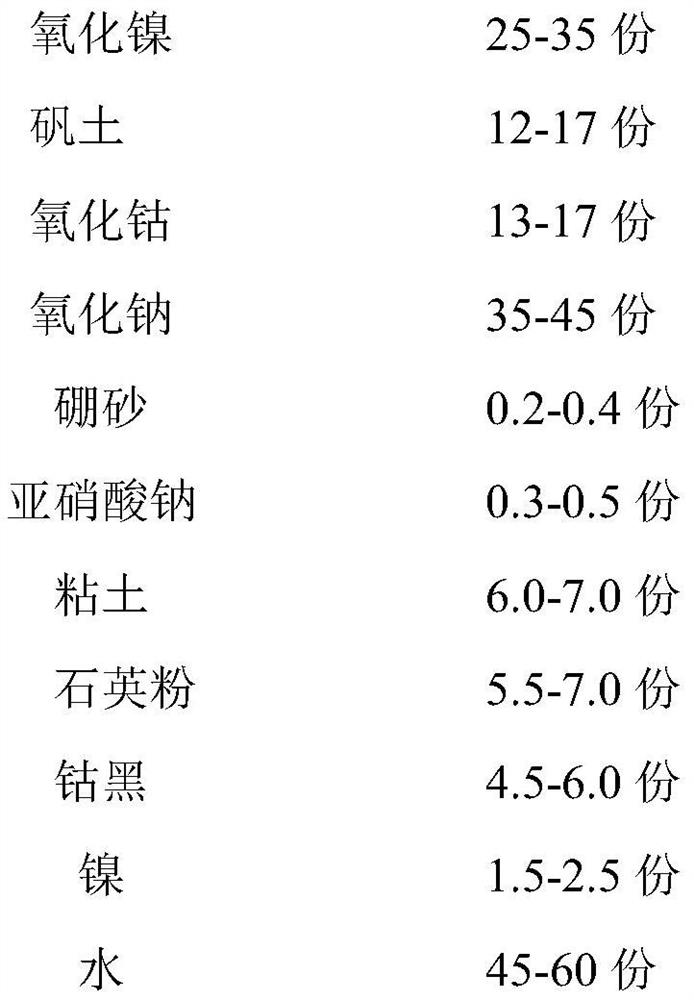

[0033] S1. The raw materials for preparing the glaze are as follows:

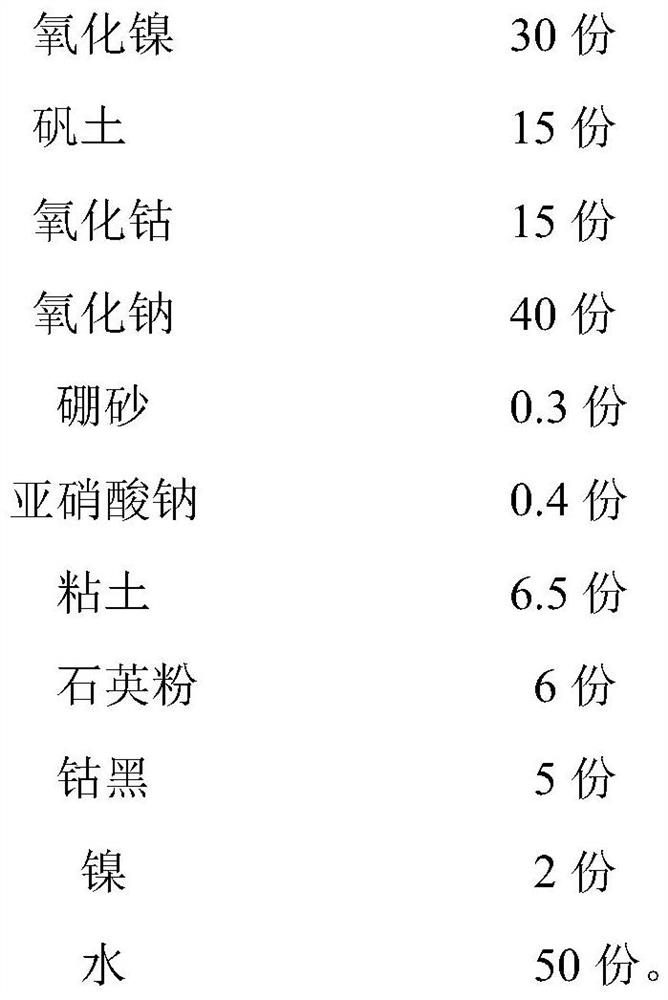

[0034]

[0035]

[0036] S2. Mix and ball-mill the above-mentioned raw materials to obtain a glaze slurry;

[0037] Load 100kg of the above solid raw material mixture, configure 120kg of ball stones (40mm ball stones and 60mm ball stones are configured at a ratio of 1:1), add 50kg of water; lock the ball mill cover, start the ball mill operation, ball mill at 1000r / min for 300min, ball mill The final glaze slurry fineness is 100% and passes through 60-80 mesh stainless steel mesh sieve material.

[0038] S3. High-temperature degreasing of the fire cover blank. Turn on the high-temperature furnace degreasing switch. When the temperature of the high-temperature furnace is raised to 550°C, the degreasing time is 10 minut...

Embodiment 2

[0044] Preparation of enamel on the surface of the fire cover of the burning appliance, the material of the fire cover of the burning appliance is iron; including the following steps:

[0045] S1. The raw materials for preparing the glaze are as follows:

[0046]

[0047]

[0048] S2. Mix and ball-mill the above-mentioned raw materials to obtain a glaze slurry;

[0049] Load 100kg of the above-mentioned solid raw material mixture, configure 115kg of ball stones (40mm ball stones and 60mm ball stones are configured at a ratio of 1:1), add 50kg of water; lock the ball mill cover, start the ball mill operation, ball mill at 1050r / min for 290min, ball mill The final glaze slurry fineness is 100% and passes through 60-80 mesh stainless steel mesh sieve material.

[0050] S3. High-temperature degreasing of the fire cover blank, turn on the degreasing switch of the high-temperature furnace, and when the temperature of the high-temperature furnace is raised to 600°C, the degrea...

Embodiment 3

[0056] Preparation of enamel on the surface of the fire cover of the burning appliance, the material of the fire cover of the burning appliance is iron alloy; including the following steps:

[0057] S1. The raw materials for preparing the glaze are as follows:

[0058]

[0059] S2. Mix and ball-mill the above-mentioned raw materials to obtain a glaze slurry;

[0060] Load 100kg of the above-mentioned solid raw material mixture, configure 110kg of ball stones (40mm ball stones and 60mm ball stones are configured at a ratio of 1:1), add 50kg of water; lock the ball mill cover, start the ball mill operation, ball mill at 1100r / min for 280min, ball mill The final glaze slurry fineness is 100% and passes through 60-80 mesh stainless steel mesh sieve material.

[0061] S3. High-temperature degreasing of the fire cover blank, turn on the degreasing switch of the high-temperature furnace, and when the temperature of the high-temperature furnace is raised to 650°C, the degreasing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com