Method for extracting platycladus orientalis (L.) franco essential oil through microorganism system fermentation

A technology of thuja essential oil and microorganisms, which is applied to the extraction of thuja essential oil and the field of fermentation and extraction of thuja essential oil by using microbial systems, to achieve the effects of increasing extraction rate, increasing yield, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

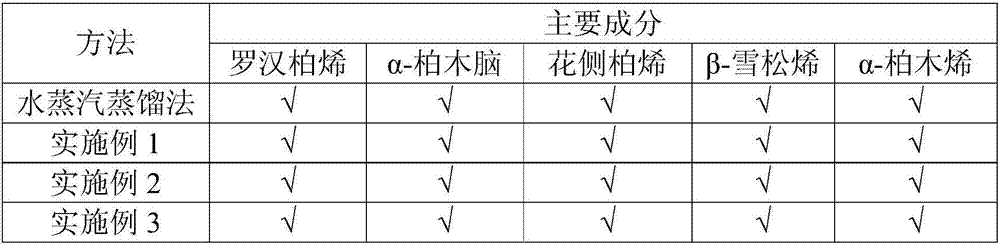

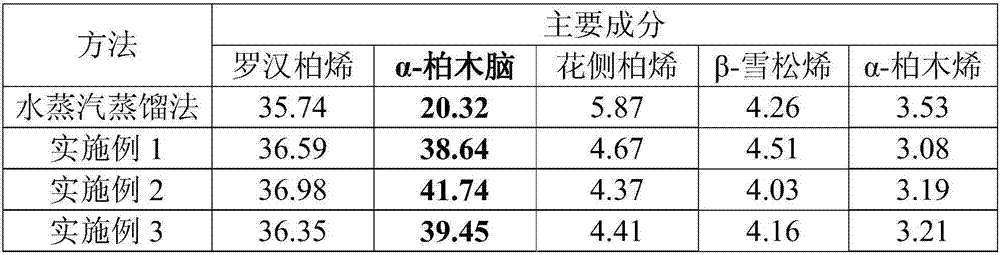

Embodiment 1

[0019] Get 10kg of thuja raw material, crush it into sawdust; adjust the moisture content to 40%, add 2% sucrose, 0.5% yeast extract, 0.5% Trichoderma viride spore powder (200 million / g), mix well and place in a solid reactor Fermentation at 25-30°C with intermittent aeration and stirring for 7-15 days, the aeration rate is 0.07-0.1vvm, 1-3 minutes each time, to promote the disintegration of thuja raw material cellulose or lignin structure; then fermented The Thuja raw material was placed in a steam distillation extractor for distillation and extraction for 7 hours, the oil yield was 1.13kg, and the essential oil yield was 11.3%.

Embodiment 2

[0021] Get 10kg of thuja raw material, crush it into sawdust; adjust the moisture content to 50%, add 2% sucrose, 0.5% yeast extract, 5% Trichoderma viride spore powder (2 billion / g), mix well and place in a solid reactor Fermentation at 25-30°C with intermittent aeration and stirring for 7-15 days, the aeration rate is 0.07-0.1vvm, 1-3 minutes each time, to promote the disintegration of thuja raw material cellulose or lignin structure; then fermented The Thuja raw material was placed in a steam distillation extractor for distillation and extraction for 7 hours, the oil yield was 1.511kg, and the essential oil yield was 15.1%.

Embodiment 3

[0023] Get 10kg of thuja raw material, crush it into sawdust; adjust the moisture content to 45%, add 2% sucrose, 0.5% yeast extract, 2.5% Trichoderma korningii spore powder (200 million / g) and 2.5% Trichoderma viride spore powder (1,000,000,000 / g), mixed evenly, placed in a solid reactor, and fermented at 25-30°C with intermittent aeration for 7-15 days, with an aeration rate of 0.07-0.1vvm, 1-3 minutes each time, to promote The cellulose or lignin structure of the cypress raw material was disintegrated; then the fermented thuja raw material was distilled and extracted for 7 hours in a steam distillation extractor, and the oil yield was 1.31kg, and the yield of essential oil was 13.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com