Method for improving organic field effect transistor mobility through rapid annealing

A rapid annealing and mobility technology, which is used in the manufacture of electrical solid state devices, semiconductor devices, semiconductor/solid state devices, etc., to achieve the effect of easy preparation, optimization of mobility and surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for rapid annealing to improve the mobility of an organic field effect transistor, comprising:

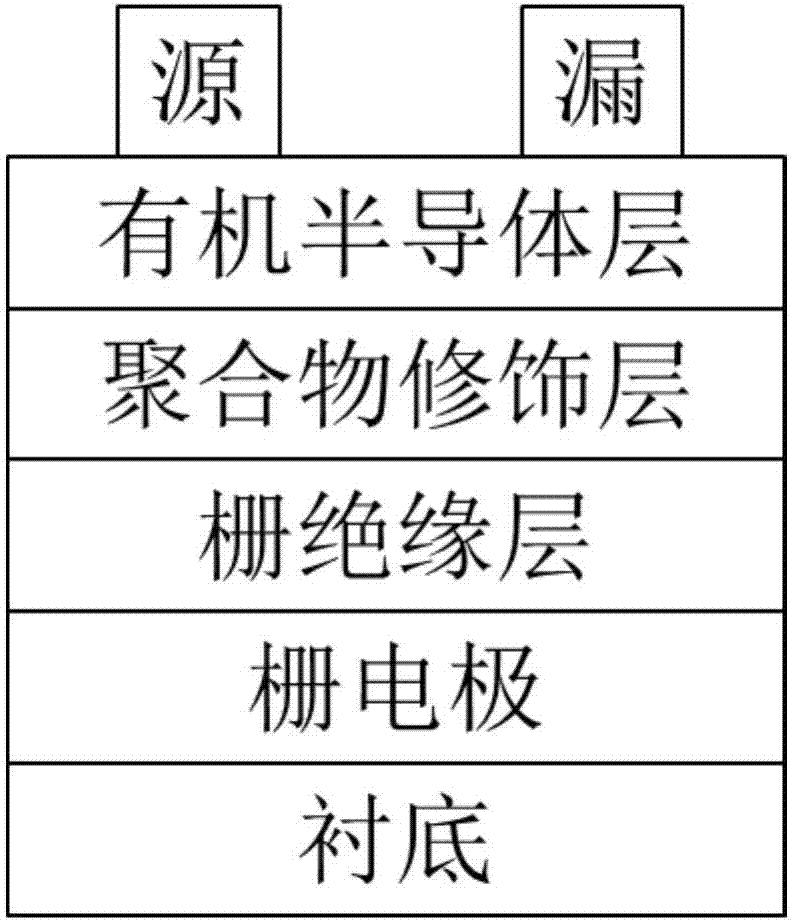

[0044] (1) Prepare an organic field-effect transistor with a polymer modification layer, the schematic diagram of which is shown in figure 1 shown;

[0045] It specifically includes the following steps: during actual preparation, the room temperature in the laboratory is kept at about 25° C., and the indoor humidity is kept below 30%.

[0046] (a) configuration polymer poly(4-vinylphenol) (PVP, molecular weight Mw=11kg / mol, T g =130°C) solution, PVP was formulated into a solution with ethyl acetate as a solvent, and the solubility was 3mg / ml;

[0047] (b) Select heavily doped silicon with 300nm silicon dioxide on the surface as the substrate and gate insulating layer, use acetone, ethanol, and deionized water to clean it with 100KHz ultrasonic waves for 10 minutes, and then dry it in a vacuum oven at 120°C ;

[0048] (c) putting the substrate dried in step (b) i...

Embodiment 2

[0054] A method for rapid annealing to improve the mobility of an organic field effect transistor, comprising:

[0055] (1) Prepare an organic field-effect transistor with a polymer modification layer, the schematic diagram of which is shown in figure 1 shown;

[0056] It specifically includes the following steps: during actual preparation, the room temperature in the laboratory is kept at about 25° C., and the indoor humidity is kept below 30%.

[0057] (a) configuration polymer polystyrene (PS, molecular weight Mw=250kg / mol, T g =100°C) solution, the PS is prepared into a solution with toluene as a solvent, and the solubility is 3mg / ml;

[0058] (b) Select heavily doped silicon with 300nm silicon dioxide on the surface as the substrate and gate insulating layer, use acetone, ethanol, and deionized water to clean it with 100KHz ultrasonic waves for 10 minutes, and then dry it in a vacuum oven at 120°C ;

[0059] (c) putting the substrate dried in step (b) into ultraviolet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com