Pre-treatment device and method for hydrochloric acid pickling wastewater of steel products

A technology of pretreatment device and pickling wastewater, which is applied in energy wastewater treatment, metallurgical wastewater treatment, multi-stage water treatment, etc. The effect of simplification, good processing depth, and less infrastructure investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

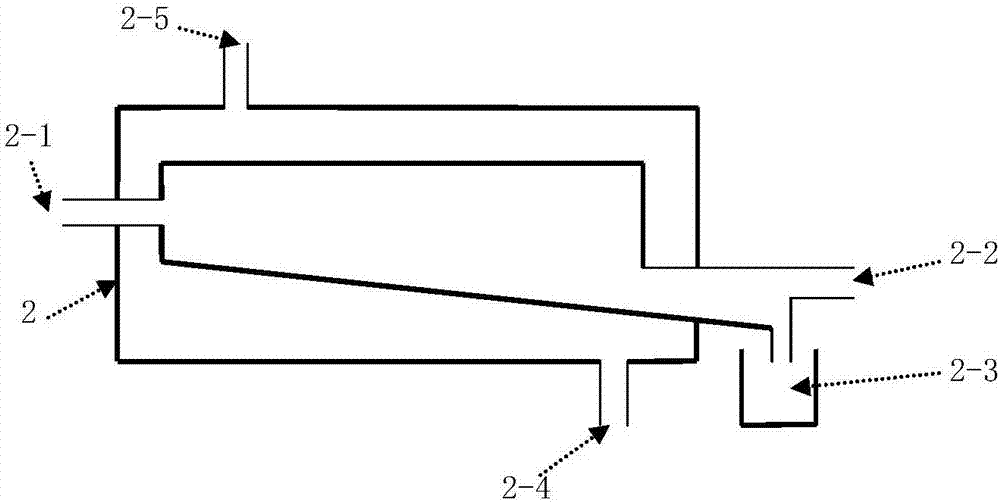

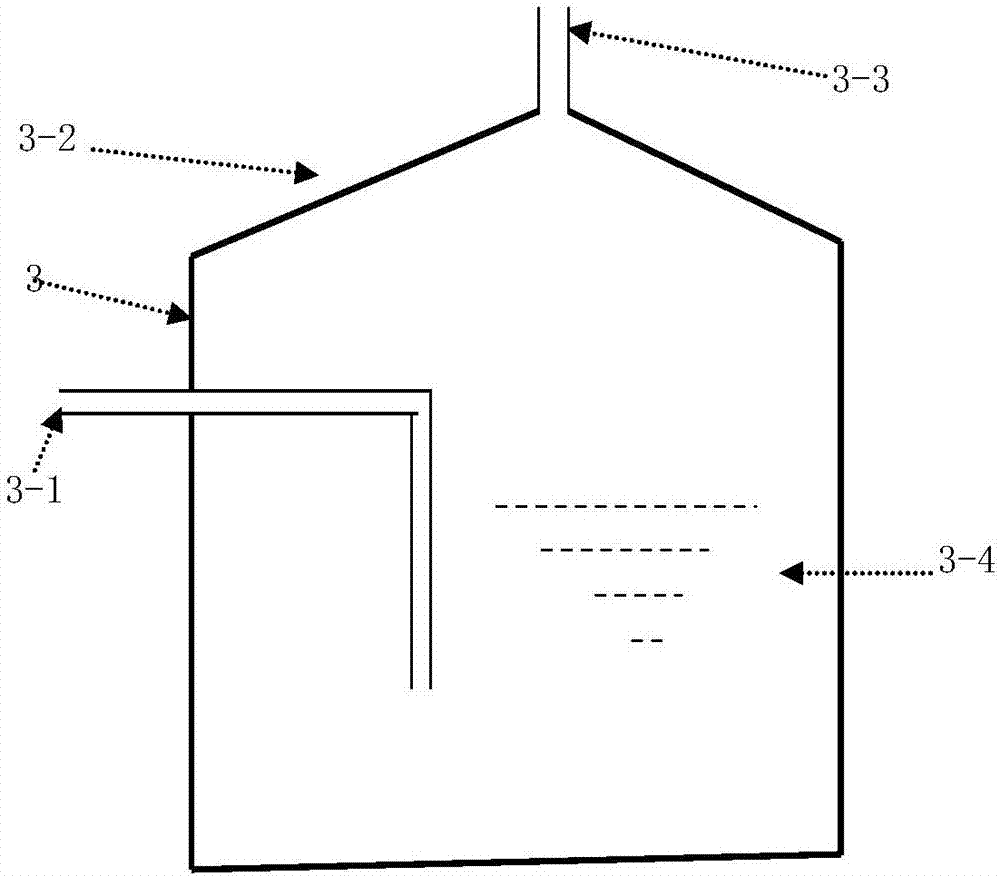

[0037] like Figure 1 to Figure 6 As shown, a steel hydrochloric acid pickling wastewater pretreatment device of the present invention includes a rotary solar water heater, a negative pressure evaporation pool 1, a condensation pool 2, a gas absorption pool 3, an oxidation precipitation pool 4 and a multi-layer filter tower 5.

[0038] The rotary solar water heater includes a base, a hot water pipe, a water heater inlet pipe, a water heater outlet pipe and a water pump, and the water heater inlet pipe communicates with the water pump.

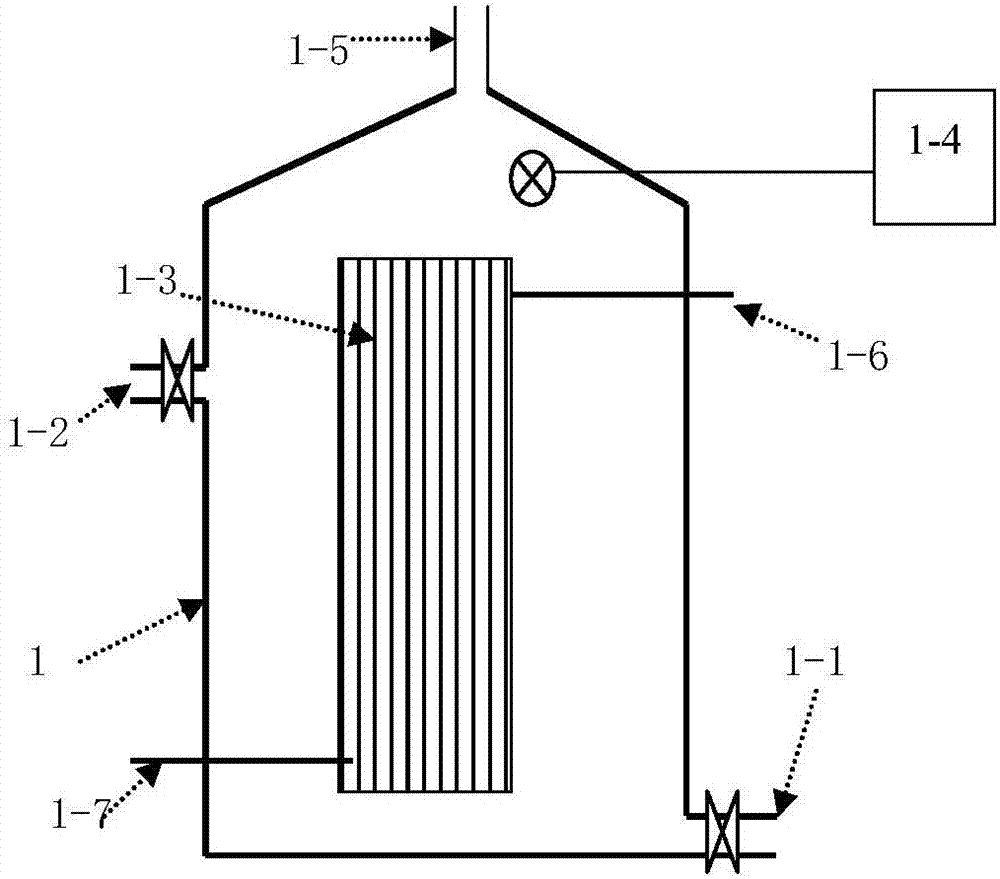

[0039] The negative pressure evaporation pool 1 includes a negative pressure evaporation pool inlet pipe 1-1, a negative pressure evaporation pool outlet pipe 1-2, a heat exchanger 1-3, a pressure control device 1-4, and a negative pressure evaporation pool outlet pipe 1 -5, the inlet pipe 1-1 of the negative pressure evaporation pool and the outlet pipe 1-2 of the negative pressure evaporation pool are provided with switching valves; the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com