A kind of improved production process of crotonaldehyde

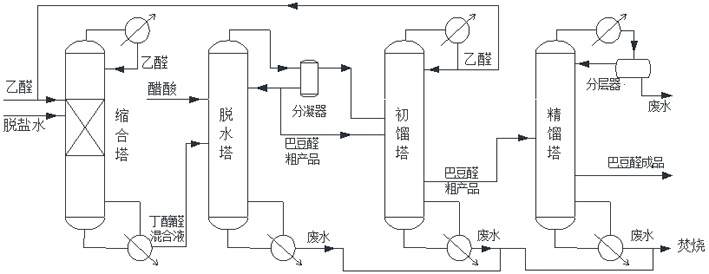

A production process and a crotonaldehyde technology are applied in the field of improved production technology of crotonaldehyde, can solve the problems such as inability to overcome the difficulty of accurate control of the reaction process, and achieve the effects of improving the conversion rate of condensation reaction and environmental protection, reducing the amount of waste water produced, and reducing the amount of consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The filler in the reaction section of the condensation tower is a solid-supported alkaline ionic liquid catalyst 1-butyl-3-methylimidazolium hydroxide [BmIm]OH, and the height of the filler is 4m. The acetaldehyde distillation section and the butanol aldehyde concentration section are both For 5 trays. With a flow rate of 3600L / h, acetaldehyde is fed from the upper part of the reaction section of the condensation tower, filled with N 2 The pressure at the top of the condensation tower is 150KPa, and the desalted water is fed from the upper part of the reaction section at a flow rate of 720L / h, so that the temperature of the condensation reaction section is maintained at 48-49°C, and acetaldehyde is catalyzed by the solid-supported alkaline ionic liquid catalyst A condensation reaction occurs under the action to generate butanol aldehyde, and the temperature of the tower reactor is controlled at 74-75°C. The acetaldehyde evaporated from the top of the tower is fully ref...

Embodiment 2

[0023] The filler in the reaction section of the condensation tower is a solid-supported alkaline ionic liquid catalyst 1-butyl-3-methylimidazolium hydroxide [BmIm]OH, and the height of the filler is 5m. The acetaldehyde distillation section and the butanol aldehyde concentration section are both For 5 trays. With a flow rate of 3400L / h, acetaldehyde is fed from the upper part of the reaction section of the condensation tower, filled with N 2 The pressure at the top of the condensation tower is 145KPa, and the desalted water is fed from the upper part of the reaction section at a flow rate of 720L / h, so that the temperature of the condensation reaction section is maintained at 47-49°C, and acetaldehyde is catalyzed by the solid-supported alkaline ionic liquid catalyst Condensation reaction occurs under the action to generate butanol aldehyde, and the temperature of the tower reactor is controlled at 72-74°C. The acetaldehyde evaporated from the top of the tower is fully reflu...

Embodiment 3

[0028] The filler in the reaction section of the condensation tower is a solid-supported alkaline ionic liquid catalyst 1-butyl-3-methylimidazolium hydroxide [BmIm]OH, and the height of the filler is 5m. The acetaldehyde distillation section and the butanol aldehyde concentration section are both For 5 trays. With a flow rate of 3000L / h, acetaldehyde is fed from the upper part of the reaction section of the condensation tower, filled with N 2 The pressure at the top of the condensation tower is 140KPa, and the desalted water is fed from the upper part of the reaction section at a flow rate of 610L / h, so that the temperature of the condensation reaction section is maintained at 47-49°C, and acetaldehyde is catalyzed by the solid-supported alkaline ionic liquid catalyst Condensation reaction occurs under the action to generate butanol aldehyde, and the temperature of the tower reactor is controlled at 73-75°C. The acetaldehyde evaporated from the top of the tower is fully reflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com