Slotless micro-arc oxidation treatment technology and movable type device of magnesium alloy

A technology of micro-arc oxidation and treatment process, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., which can solve the problems of inflexible micro-arc oxidation treatment device and cumbersome treatment methods, and achieve increased portability and electrolytic effect Good, Simple Ingredients Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

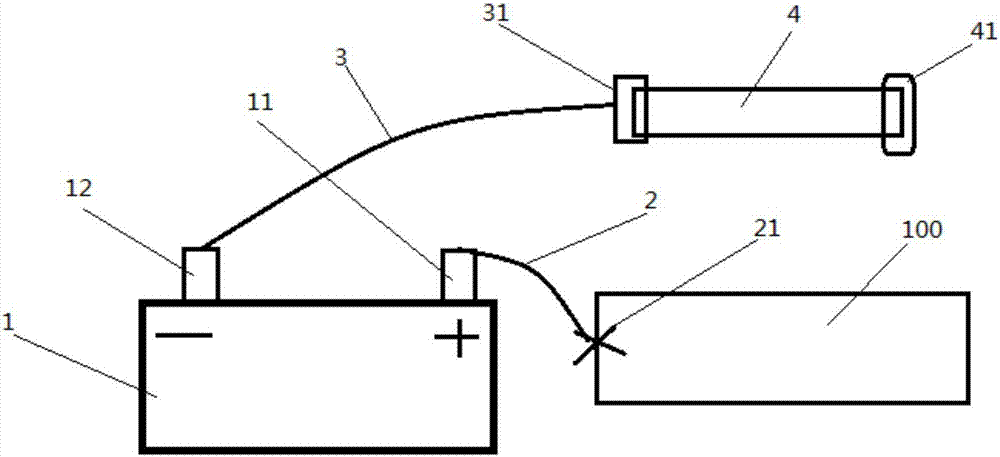

[0038] see figure 1 , a kind of mobile magnesium alloy grooveless micro-arc oxidation processing equipment provided by the present invention, comprising: a power supply 1; The clamping of the workpiece 100 forms a conductive connection; one end of the negative power supply line 3 is connected to the negative pole 12 of the power supply 1, and the other end is provided with a clamping part 31; The clamping portion 31 is conductively connected, and the other end is sleeved with an electrolyte adsorption sleeve 41 for absorbing the electrolyte.

[0039] In addition, the electrolyte adsorption sleeve 41 is a fabric.

[0040] A mobile grooveless micro-arc oxidation treatment process for magnesium alloys provided by the present invention comprises the following steps:

[0041] 1) Take a magnesium alloy workpiece 100 to be processed, and perform pre-treatments such as welding, grinding and smoothing, and the operator wears goggles and rubber gloves;

[0042] 2) Conductively connec...

Embodiment 2

[0048] The electrolyte solution in step 3) includes the following components by weight percentage: KOH: 10wt%, KF: 8wt%, the rest is water, the temperature of the electrolyte is 0°C, the power-on time is 3 seconds, the voltage is 200V, and the current is 5A / square decimeter.

[0049] All the other are with embodiment 1.

Embodiment 3

[0051] The electrolyte solution in step 3) includes the following components by weight percentage: KOH: 7wt%, KF: 10wt%, the rest is water, the temperature of the electrolyte is 20°C, the power-on time is 4 seconds, the voltage is 220V, and the current is 8A / square decimeter.

[0052] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com