A preparation method of ultra-low molecular weight pectin rich in RG-I

A technology of RG-I and molecular weight, which is applied in the field of polysaccharide degradation, can solve problems such as environmental pollution, limited degradation ability, and reduced biological activity, and achieve the effects of environmental protection and pollution-free process conditions, improved comprehensive utilization rate, and simple degradation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

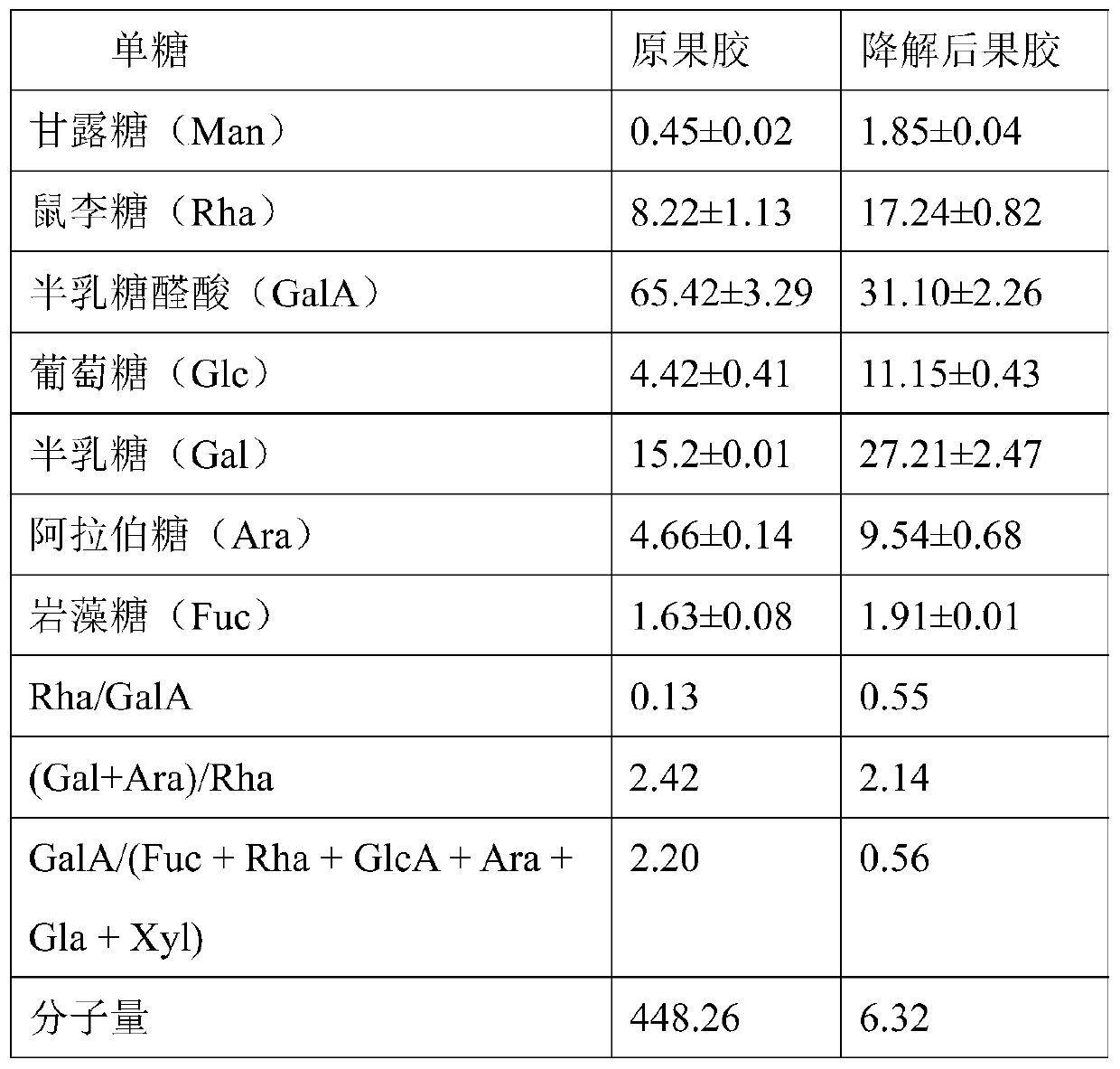

Embodiment 1

[0023] (1) Take 25mL distilled water, add 3mol / L HCl solution, adjust the pH to 3.0 with a pH meter, add FeCl 2 4H 2 O, configured as 0.5mmol / L Fe 2+ solution A;

[0024] (2) Dissolve 60 mg of pectin (Sigma company) in 25 ml of solution A, and after fully dissolving, transfer it to an ultrasonic tube (inner diameter 3 cm);

[0025] (3) Place it in a constant temperature bath at 30°C, place the ultrasonic probe at 1.5cm below the liquid surface for ultrasonic treatment, and add 50μL of 5mol / LH at the same time 2 o 2 solution, set the ultrasonic intensity to 1.5W / mL, and sonicate for 40 minutes;

[0026] (4) Add excess sodium bisulfite to the degradation solution to reduce excess hydrogen peroxide to terminate the reaction;

[0027] (5) passing the solution treated in step 4 through a cation exchange resin column, and controlling the flow rate to be 0.5mL / min, so that the cation exchange resin replaces the metal cations therein;

[0028] (6) Centrifuge the replaced solutio...

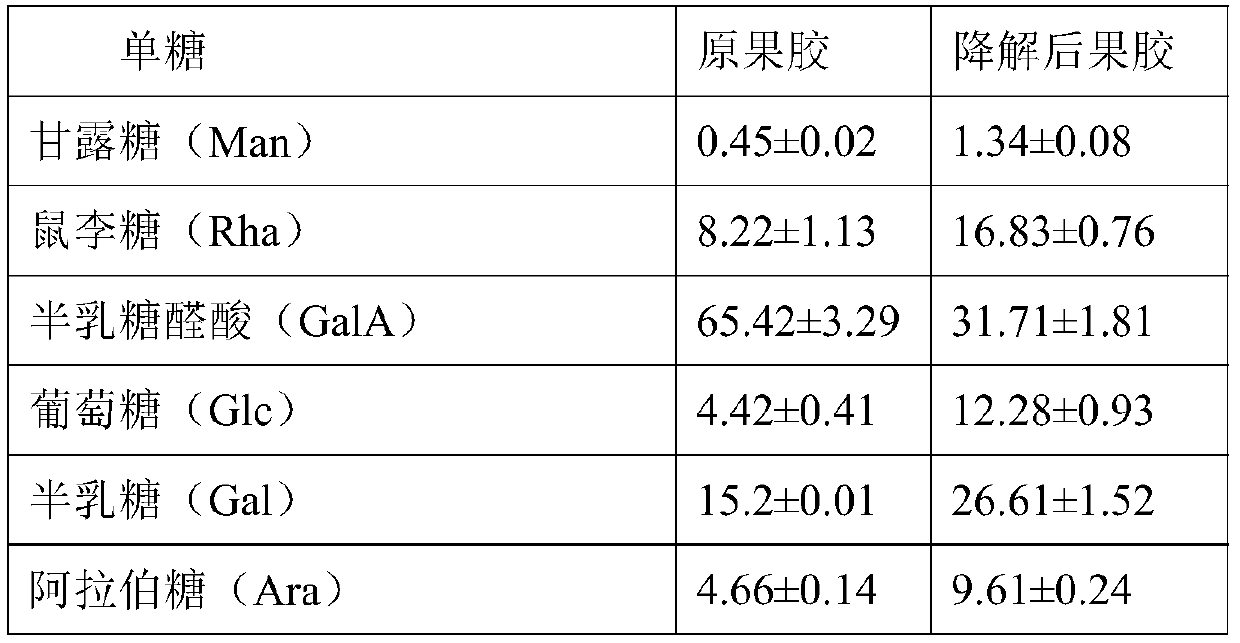

Embodiment 2

[0034] (1) Take 100mL distilled water, add 3mol / L HCl solution, adjust the pH to 4.0 with a pH meter, add FeCl 2 4H 2 O, configured as 2mmol / L Fe 2+ solution A;

[0035] (2) Dissolve 500 mg of pectin (Sigma company) in 100 ml of solution A, and after fully dissolving, transfer it to an ultrasonic tube (inner diameter 6 cm);

[0036] (3) Place it in a constant temperature bath at 30°C, place the ultrasonic probe at 1.5 cm below the liquid surface for ultrasonic treatment, and add 800 μL of high-concentration H 2 o 2 solution, set the ultrasonic intensity to 4.0W / mL, and sonicate for 30 minutes;

[0037] (4) Add excess sodium bisulfite to the degradation solution to reduce excess hydrogen peroxide to terminate the reaction;

[0038] (5) passing the solution treated in step 4 through a cation exchange resin column, and controlling the flow rate to be 1.0mL / min, so that the cation exchange resin replaces the metal cations therein;

[0039] (6) Centrifuge the replaced solutio...

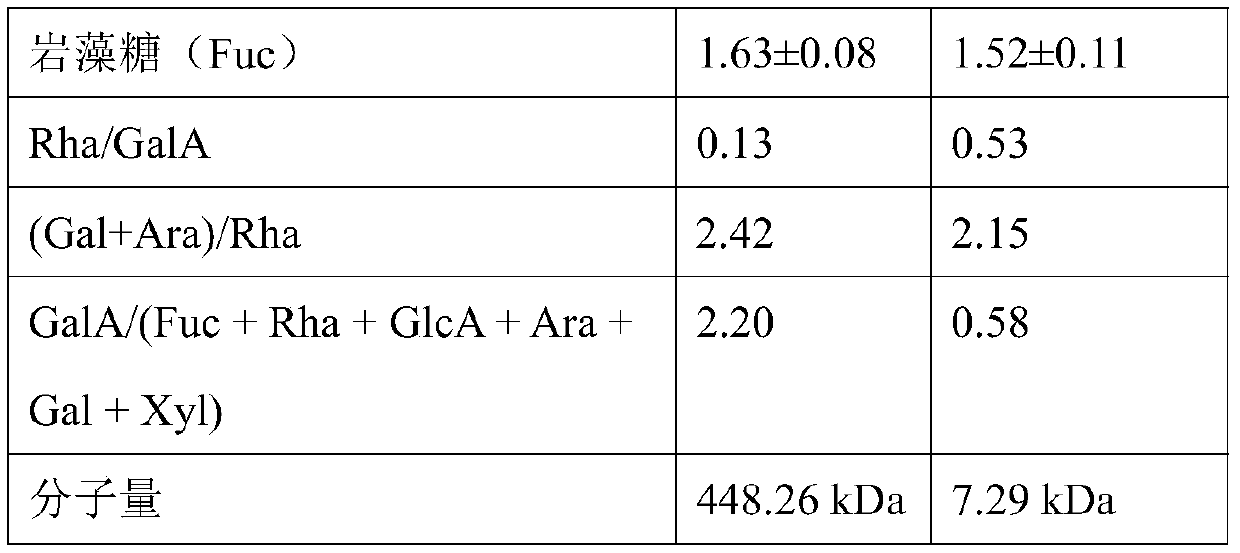

Embodiment 3

[0046] (1) Take 1000mL distilled water, add 3mol / L HCl solution, adjust the pH to 5.0 with a pH meter, add FeCl 2 4H 2 O, configured as 5mmol / L Fe 2+ solution A;

[0047] (2) Get 10g pectin (Sigma company) and dissolve in 1000ml solution A, after fully dissolving, transfer to the ultrasonic tank;

[0048] (3) Place it in a constant temperature bath at 40°C, and add 20mL of high-concentration H 2 o 2 solution, set the ultrasonic intensity to 4.0W / mL, and sonicate for 30 minutes;

[0049] (4) Add excess sodium bisulfite to the degradation solution to reduce excess hydrogen peroxide to terminate the reaction;

[0050] (5) passing the solution treated in step 4 through a cation exchange resin column, and controlling the flow rate to be 2.0mL / min, so that the cation exchange resin replaces the metal cations therein;

[0051] (6) Centrifuge the replaced solution at 4000r / min, take the supernatant, and adjust the pH to 6.0;

[0052] (7) Transfer the above solution to a 500Da d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com