Asphalt anti-aging modifier

An anti-aging and modifier technology, applied in building components, building insulation materials, construction, etc., can solve the problems of rising production costs and unfavorable large-scale promotion, and achieve cost saving, low cost, and improved compaction performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

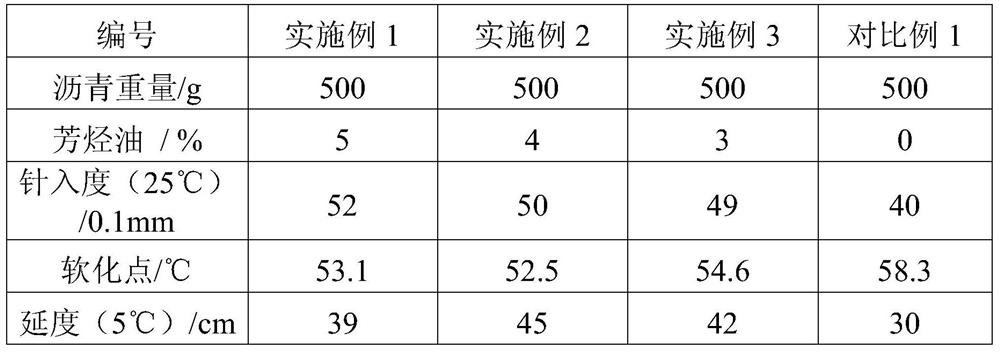

Embodiment 1

[0029] The asphalt anti-aging modifier in this embodiment is composed of the following raw materials by weight: 2.5 parts of furfural extraction oil (aromatic content of 70%), 3 parts of polyethylene, 1.2 parts of sodium butylnaphthalene sulfonate, 0.8 parts of polyurethane, propylene 0.2 part of alcohol, 3 parts of high aluminum powder, 0.5 part of octadecyl primary amine salt.

[0030] The method of use is as follows:

[0031] Put 500g 70# bitumen in a 1-liter reaction vessel, heat the bitumen to 150°C, then add 5% furfural extract oil (aromatic content 70%), which accounts for the weight of the bitumen, into the bitumen, and use a high-speed shear emulsifier to continuously Shearing is accelerated and the remaining components are added in the proportions above. The high-speed shearing emulsifier was kept at 3000 r / min and continued to stir for 30 minutes to obtain the modified asphalt product.

Embodiment 2

[0033] The asphalt anti-aging modifier in this example is composed of the following raw materials by weight: 2.0 parts of furfural extraction oil (aromatic content of 90%), 1 part of polyethylene, 1.5 parts of sodium butylnaphthalene sulfonate, 1.6 parts of polyurethane, propylene 0.6 part of alcohol, 2 parts of high aluminum powder, 1.2 part of octadecyl primary amine salt.

[0034] The method of use is as follows:

[0035] Put 500g 70# bitumen in a 1-liter reaction vessel, heat the bitumen to 150°C, then add 4% furfural extraction oil (90% aromatic hydrocarbon content) to the bitumen, and use a high-speed shear emulsifier to continuously accelerate shearing. , and then add the rest of the components in the above proportions. The high-speed shearing emulsifier was kept at 3000 r / min and continued to stir for 30 minutes to obtain the modified asphalt product.

Embodiment 3

[0037] The asphalt anti-aging modifier in this example is composed of the following raw materials in weight fraction: 3 parts of furfural extraction oil (aromatic content 80%), 1.2 parts of polyethylene, 2 parts of sodium butylnaphthalene sulfonate, 2 parts of polyurethane, propylene 1.5 parts of alcohol, 0.2 part of high alumina powder, 0.2 part of octadecyl primary amine salt.

[0038] The method of use is as follows:

[0039]Put 500g of 70# asphalt in a 1-liter reaction vessel, heat the asphalt to 150°C, then add 3% furfural extract oil (80% aromatic content) into the asphalt, and use a high-speed shear emulsifier to continuously accelerate the shearing , and then add the remaining components according to the above ratio. The high-speed shear emulsifier keeps at 3000r / min and continues to stir for 30 minutes to obtain the modified asphalt product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com