Double-layer composite pipe and preparation method thereof

A double-layer composite, aluminum alloy pipe technology, applied in the field of pipe fittings processing, can solve the problems of cracking and thinning of the pipe fitting forming area, and achieve the effects of convenient and cheap preparation, simple preparation, and simple process realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

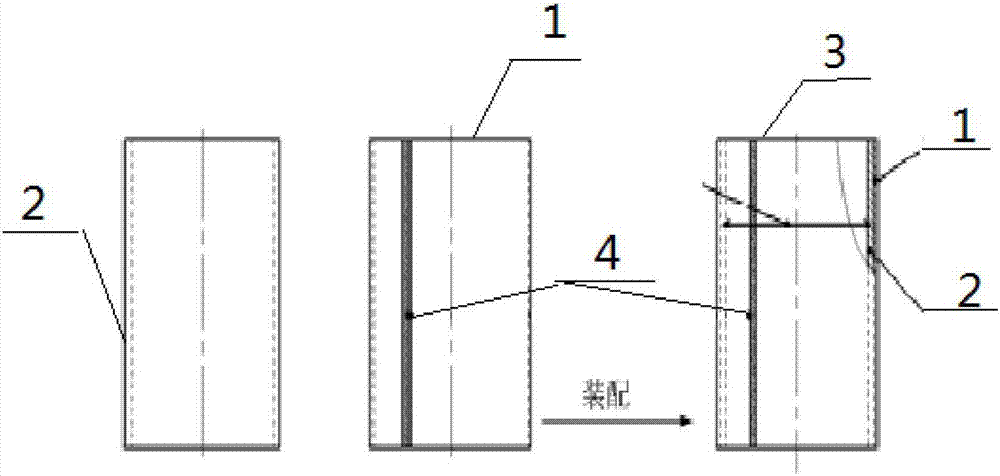

[0040] Such as Figure 1-4 As shown, the present embodiment provides a method for forming a double-layer composite pipe, comprising the following steps:

[0041] Assembly: the hollow aluminum alloy tube blank 2 is placed inside the hollow carbon steel tube blank 1 to form a double-layer composite tube blank 3;

[0042] Specifically, such as figure 1 As shown, the welding joint 4 of the hollow carbon steel pipe billet 1 needs to be cleaned and flattened. The inner diameter is designed according to the basic size of the outer diameter of the hollow aluminum alloy pipe billet 2, and the clearance of the base shaft is matched with the B11 grade design, and the same precision level is used to control the welding of the hollow carbon steel pipe billet. 1 cylindricity. Then, two hollow carbon steel tube blanks 1 and hollow aluminum alloy tube blanks 2 of different materials are assembled to obtain a double-layer composite tube blank 3 .

[0043] Preferably, the hollow carbon steel...

Embodiment 2

[0064] This embodiment adopts the method as described in Example 1. The hollow carbon steel pipe billet 1 adopts Q235 plate welded steel pipe, and the hollow aluminum alloy pipe billet 2 adopts AA5052 extruded pipe material. Through the above steps, the convex ring pipe fittings are formed. For details, see Figure 5 .

[0065] In addition, before the AA5052 pipe is formed, it can also be subjected to heat treatment, specifically annealing treatment, in order to increase the elongation. The strengthening of AA5052 can be strengthened by strain, that is, the greater the degree of bulging, the better the strengthening effect . The main functions of AA5052 in this embodiment are anti-corrosion, energy absorption and weight reduction, while the stiffness and strength of the components are mainly realized by Q235 plate welded steel pipes.

Embodiment 3

[0067] This embodiment adopts the method as described in Example 1. The hollow carbon steel pipe billet 1 adopts 304 stainless steel coil welded pipe, and the hollow aluminum alloy pipe billet 2 adopts AA6061 extruded pipe material. Through the above steps, hexahedral pipe fittings are formed. For details, see Figure 6 .

[0068] In addition, before the AA6061 pipe is formed, heat treatment can be carried out to strengthen the material. It should be understood that solution treatment is selected for the heat treatment of the 6-series and 7-series aluminum alloy extruded pipes.

[0069] Immediately after solution treatment, it is assembled with 304 stainless steel coil welded pipe and expanded into the target shape, and then artificially aged to restore the strength of the aluminum alloy pipe. The artificial aging conditions of AA6061 pipe fittings will not affect the material properties of 304 stainless steel, which is also an important reason why they can be used in combinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com