Anorthite micro-crystal transparent glaze and preparation method thereof

A manufacturing method and transparent glaze technology, applied in the field of ceramic glaze, can solve the problem of developing microcrystalline transparent glaze, affecting the light transmittance of the glaze layer, etc., and achieve good wear resistance, high glaze surface hardness and scratch resistance. and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

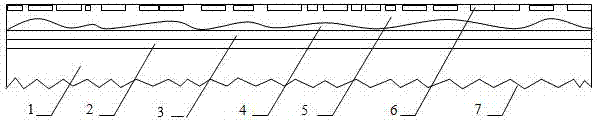

Image

Examples

Embodiment 1

[0024] The anorthite microcrystalline transparent glaze of the present embodiment is made up of the component of following weight fraction: Na 2 O: 3.04%; K 2 O: 3.63%; Al 2 o 3 : 16.66%; CaO: 16.66%; MgO: 1.90%; ZnO: 1.90%; high boron frit: 2.91%; SiO 2 : 53.30%.

[0025] Calculate used raw material formula according to above formula proportion, select 47.9g potassium albite feldspar, 23.6g calcite, 3.3g quartz powder, 16g kaolin, 4.4g talc, 2.9g high boron frit, 1.9g zinc oxide in the present embodiment as Raw material, add 60ml water ball mill, need to add 0.2% carboxymethyl cellulose and 0.2% sodium tripolyphosphate of glaze dry material weight additionally during ball milling. After ball milling, pass the glaze slurry through a 250-mesh sieve, leaving 0.1g in the sieve, and add water to adjust the density of the glaze slurry to 1.35 g / cm when glazing 3 , spray glaze, keep warm at 1200°C for 40 minutes, then cool down to 880°C and keep warm for 30 minutes and fire to ...

Embodiment 2

[0028] The anorthite microcrystalline transparent glaze of the present embodiment is made up of the component of following weight fraction: Na 2 O: 1%; K 2 O: 5%; Al 2 o 3 : 18%; CaO: 20%; MgO: 2%; ZnO: 2%; high boron frit: 7%; SiO 2 : 45%.

[0029] Calculate the raw material formula used according to the above formula ratio, select 37.7g potassium sodium feldspar, 27.7g calcite, 20.9g kaolin, 4.7g talc, 7g high boron frit, 2g zinc oxide as raw materials in this embodiment, add 60ml water ball mill , Need to add 0.2% carboxymethyl cellulose and 0.2% sodium tripolyphosphate of glaze dry weight additionally when ball milling. After ball milling, pass the glaze slurry through a 250-mesh sieve, leaving 0.1g in the sieve, and add water to adjust the density of the glaze slurry to 1.35 g / cm when glazing 3 , spray glaze, heat at 1215°C for 30 minutes, then lower the temperature to 880°C and hold for 30 minutes for firing to obtain anorthite microcrystalline transparent glaze.

...

Embodiment 3

[0032] The anorthite microcrystalline transparent glaze of the present embodiment is made up of the component of following weight fraction: Na 2 O: 3%; K 2 O: 3%; Al 2 o 3 : 15%; CaO: 17.5%; MgO: 3.5%; ZnO: 4.5%; high boron frit: 4.5%; SiO 2 : 49%.

[0033] Calculate the raw material formula used according to the above formula ratio, select 43.6g potassium albite feldspar, 24.4g calcite, 1.0g quartz powder, 13.8g kaolin, 8.2g talc, 4.5g high boron frit, 4.5g zinc oxide in the present embodiment Be raw material, add 60ml water ball mill, need to add the sodium tripolyphosphate of 0.3% carboxymethyl cellulose and glaze dry material weight 0.3% additionally when ball milling. After ball milling, pass the glaze slurry through a 250-mesh sieve, leaving 0.1g in the sieve, add water to adjust the density of the glaze slurry to 1.4g / cm 3 , spray glaze, keep warm at 1208°C for 35min, then cool down to 870°C and keep warm for 35min and fire to get anorthite microcrystalline transpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com