Tin/carbon composite nanofiber material for sodium battery negative electrode and preparation method of tin/carbon composite nanofiber material

A carbon nanofiber and nanofiber technology, which is applied in the field of tin/carbon composite nanofiber material for sodium battery negative electrode and its preparation, can solve the problems of poor battery cycle stability, destruction of material structural integrity, volume expansion and shrinkage, etc. , to achieve the effect of good rate performance, excellent cycle stability and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

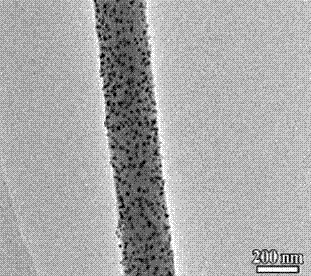

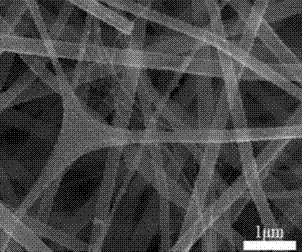

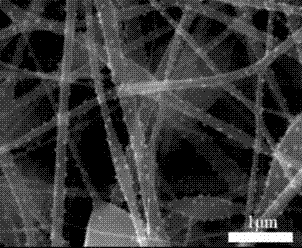

[0039] A method for preparing tin / carbon composite nanofiber material for the negative electrode of a sodium battery includes the following steps:

[0040] (1) Precursor solution preparation: Weigh 0.7 g of polyacrylonitrile and 9 g of DMF in a beaker to prepare a 10% polyacrylonitrile solution, and after sealing, use a heating stirring table to stir at a constant temperature at 60°C 2 h to obtain a light yellow transparent solution, add 0.2 g of stannous chloride dihydrate, turn off the heating device of the stirring table, and stir for 12 h at room temperature to obtain a transparent and uniform solution;

[0041] (2) Electrospinning method to prepare nanofiber membrane: the solution obtained in step (1) is used as the spinning solution into a syringe with a flat stainless steel needle, the inner diameter of the stainless steel needle is 0.7 mm; The syringe of the silk liquid is installed on the syringe pump, and the electrostatic spinning parameters are set. The electrostatic vo...

Embodiment 2

[0051] A method for preparing tin / carbon composite nanofiber material for the negative electrode of a sodium battery includes the following steps:

[0052] (1) Precursor solution preparation: Weigh 0.6 g of polyacrylonitrile and 10 g of DMF in a beaker to prepare a polyacrylonitrile solution with a mass fraction of 5%. After sealing, use a heating stirring table to stir at a constant temperature at 50°C 3 h, get a light yellow transparent solution, add 0.3 g of stannous chloride dihydrate, turn off the heating device of the stirring table, and stir at room temperature for 15 h to obtain a transparent and uniform solution;

[0053] (2) Electrospinning method to prepare nanofiber membranes: the solution obtained in step (1) is used as spinning solution into a syringe with a flat-necked stainless steel needle, the inner diameter of the stainless steel needle is 0.6 mm; The syringe of the silk liquid is installed on the syringe pump, and the electrostatic spinning parameters are set. T...

Embodiment 3

[0060] A method for preparing tin / carbon composite nanofiber material for the negative electrode of a sodium battery includes the following steps:

[0061] (1) Precursor solution preparation: Weigh 0.8 g of polyacrylonitrile and 8 g of DMF in a beaker, prepare a 15% polyacrylonitrile solution, seal it and stir at a constant temperature at 80℃ with a heating stirring table 1 h, get a light yellow transparent solution, add 0.15 g of stannous chloride dihydrate, turn off the heating device of the stirring table, and stir at room temperature for 10 h to obtain a transparent and uniform solution;

[0062] (2) Electrospinning method to prepare nanofiber membrane: the solution obtained in step (1) is used as the spinning solution into a syringe with a flat stainless steel needle, the inner diameter of the stainless steel needle is 0.8 mm; The syringe of silk liquid is installed on the syringe pump, and the electrostatic spinning parameters are set. The electrostatic voltage between the sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com