Magnetic nanoparticle, and preparation method and application thereof

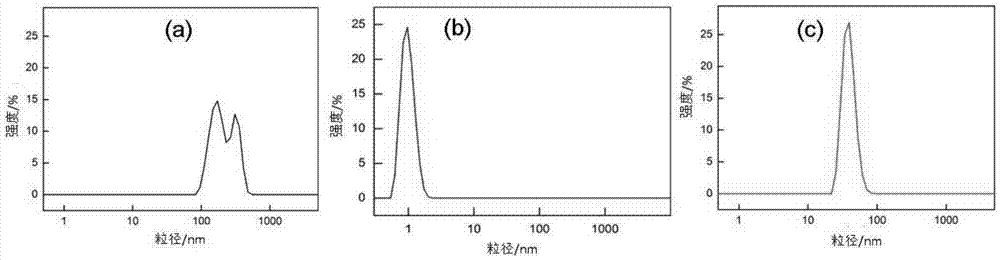

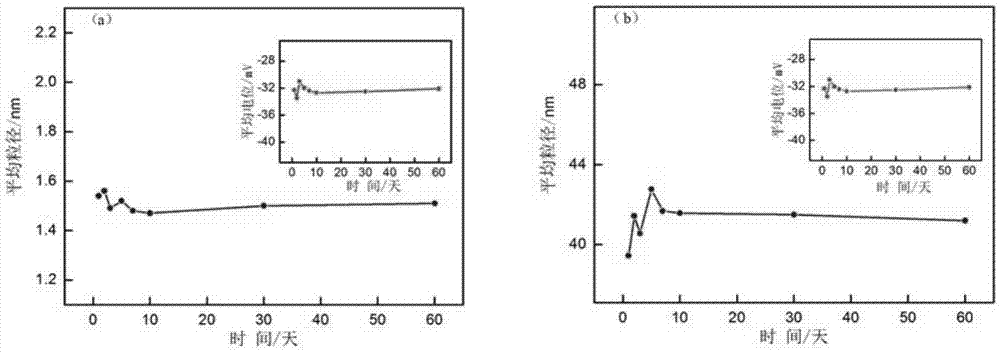

A magnetic nanoparticle and nanoparticle technology, applied in the field of materials, can solve the problems of low product yield, easy agglomeration, weak contrast signal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

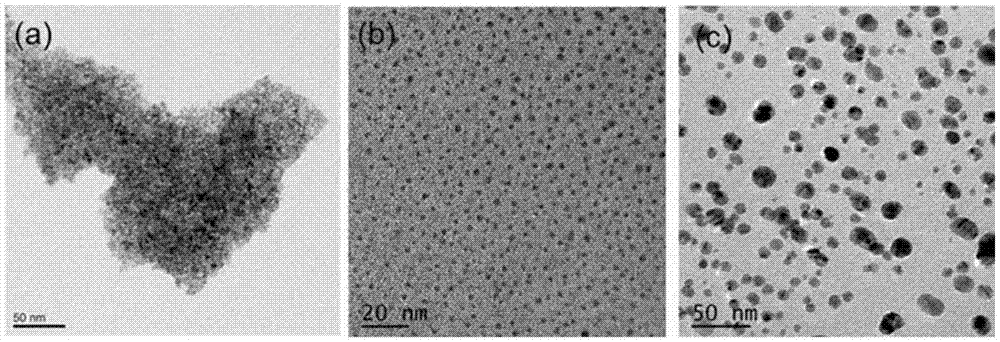

Embodiment 1

[0169] (1) Weigh 0.5406g ferric chloride hexahydrate and 0.2982g ferrous chloride tetrahydrate, and dissolve them in 40mL deionized aqueous solution under magnetic stirring at room temperature to obtain solution A for use;

[0170] (2) Add 20mL of 0.2M NaOH solution into solution A, and stir magnetically for 1 hour at 70°C;

[0171] (3) Magnetically separate and wash the above reaction liquid 4 times with deionized water to obtain about 0.22 g of the first ferrite 1;

[0172] (4) dissolving the first ferrite 1 obtained in step (3) in 90 mL of deionized aqueous solution;

[0173] (5) Measure 10 mL of glacial acetic acid (concentration ≥ 99.5%) and add it to the reaction solution obtained in step (4), shake it at 60 ° C for 5 h, then let it stand for 24 h and then magnetically stir it at 90 ° C for 2 h to obtain about 0.20 g of magnetic nano particle1;

[0174] (6) Add 20 ml of an aqueous solution containing 40 mg of polyethylene glycol to the product obtained in step (5), ult...

Embodiment 2

[0191] (1) Weigh 0.5406g ferric chloride hexahydrate and 0.2982g ferrous chloride tetrahydrate, and dissolve them in 40mL deionized aqueous solution under magnetic stirring at room temperature to obtain solution A for use;

[0192] (2) Add 20mL of 0.3M KOH solution into solution A, and stir magnetically for 1 hour at 37°C;

[0193] (3) Magnetically separate and wash the above reaction liquid 5 times with deionized water to obtain about 0.23 g of the first ferrite 2;

[0194] (4) dissolving the first ferrite 2 obtained in step (3) in 90 mL of deionized aqueous solution;

[0195] (5) Add 10 mL of hypochlorous acid (analytical pure) to the reaction solution obtained in step (4), shake at room temperature for 3 h, and let stand for 26 h to obtain about 0.07 g of magnetic nanoparticles 2;

[0196] (6) Add 20 ml of an aqueous solution containing 40 mg of polyethylene glycol to the product obtained in step (5), ultrasonically disperse for 20 min, and react with mechanical stirring f...

Embodiment 3

[0200] (1) Weigh 0.5406g ferric chloride hexahydrate and 0.2982g ferrous chloride tetrahydrate, and dissolve them in 40mL deionized aqueous solution under magnetic stirring at room temperature to obtain solution A for use;

[0201] (2) Add 40mL of 0.3M KOH solution into solution A, and stir magnetically for 1 hour at 60°C;

[0202] (3) Magnetically separate and wash the above reaction liquid 4 times with deionized water to obtain about 0.25 g of the first ferrite 3;

[0203] (4) dissolving the first ferrite 3 obtained in step (3) in 100 mL of deionized aqueous solution;

[0204] (5) Weigh 3.0 g of sodium borohydride and add it to the mixed solution obtained in step (4), put the obtained reaction solution in a water bath at 60° C. for aging treatment, the aging time is 48 hours, and obtain 0.07 g of magnetic nanoparticles 3;

[0205] (6) Add 20 ml of an aqueous solution containing 40 mg of polyethylene glycol to the product obtained in step (5), ultrasonically disperse for 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com