Preparation method of cartilage extract containing non-denatured type II collagen

A collagen and extract technology, used in chemical instruments and methods, animal/human proteins, connective tissue peptides, etc., can solve problems such as pretreatment, low extraction rate, and limited storage conditions, and achieve easy large-scale production and extraction. High-efficiency, easy-to-save effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

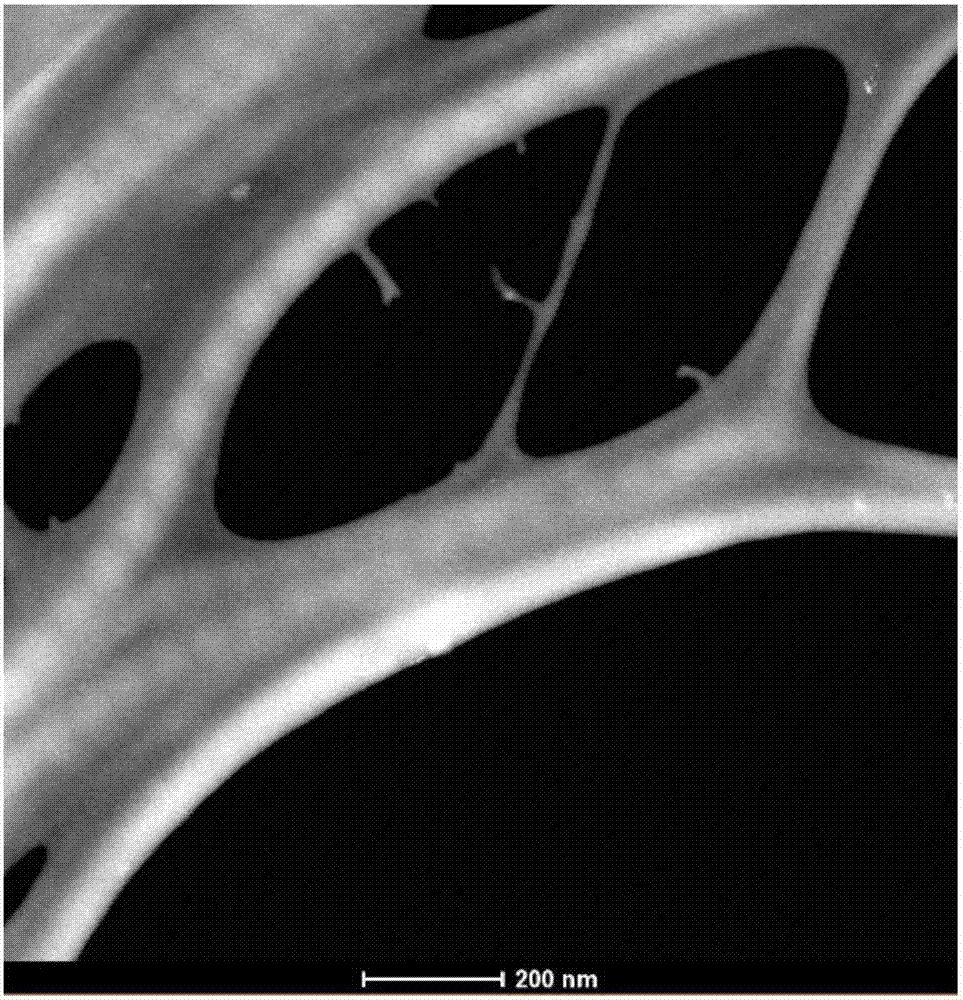

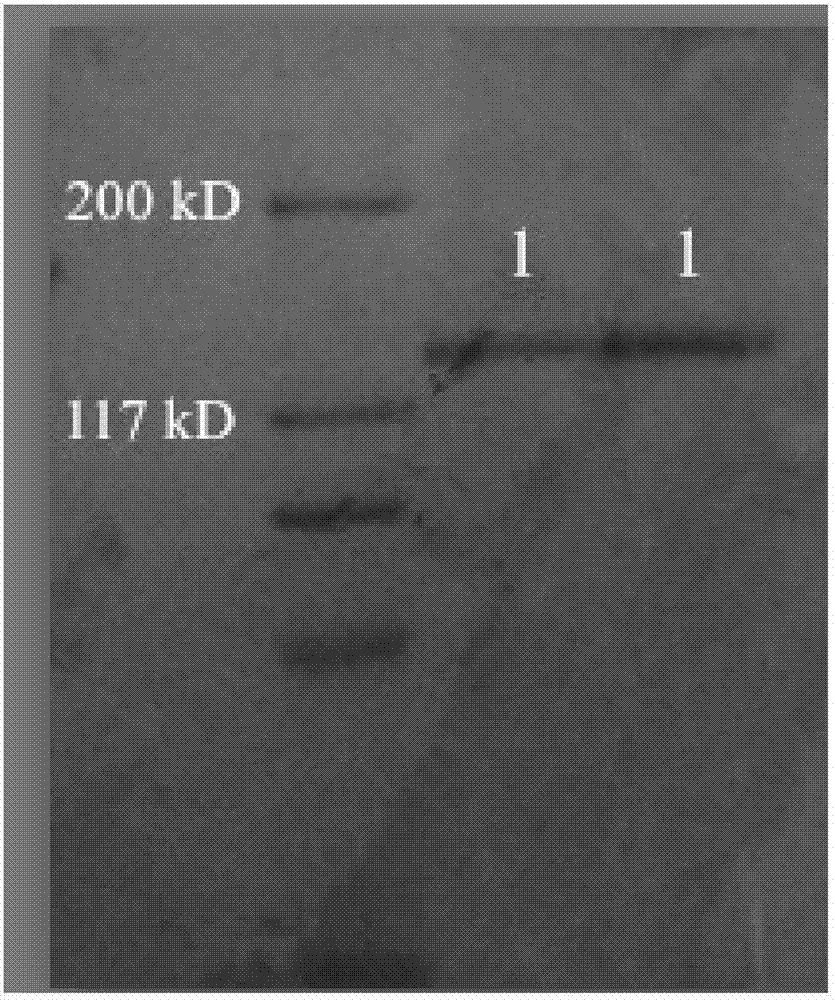

[0012] The invention provides a method for preparing a cartilage extract containing non-denatured type II collagen, which is characterized in that the method comprises the following steps in sequence: degreasing, disinfection, homogenization, enzymolysis, filtration, and drying; wherein, in the In the enzymatic hydrolysis step: adjust the pH of the slurry obtained in the homogenization step to 2.5-8.5, add 0.001%-2% of the cartilage weight of enzyme, add 1 / 20-1 / 500 of the cartilage weight of papaya And / or the clear liquid obtained by filtering the pineapple juice at low temperature, enzymatic hydrolysis for 12-48 hours, and the enzymatic hydrolysis temperature is 25-50°C.

[0013] The inventors of the present application unexpectedly found that a higher concentration of non-denatured type II collagen can be obtained by enzymatic hydrolysis under the above-mentioned enzymatic hydrolysis conditions.

[0014] In the enzymolysis step, the enzyme can use any enzyme used in the art,...

Embodiment 1

[0033] (1) Pretreatment: Select 3.5 kg of chicken breast cartilage, remove the chicken meat, fascia and red bone on the cartilage after thawing, and then cut into cubes of 3*3mm by a dicing machine.

[0034] (2) Degreasing: use a final concentration of 0.01% Na 2 CO 3 and 2% NaCl mixed degreasing agent solution 7kg, degreasing at room temperature for 4 hours, after degreasing and draining, wash with purified water to pH 6.5.

[0035] (3) Disinfection: add sodium hypochlorite solution with a concentration of 400ppm to start disinfection, and disinfect twice, each time for 12 hours. After disinfection, wash with purified water until no disinfection and no residual chlorine is detected, and the pH is controlled at 6.5-7.0.

[0036] (4) Homogenization: Add 6 kg of purified water to the cartilage dices treated in step (3), and grind the cartilage into 100-200 meshes with a colloid mill.

[0037] (5) Enzymolysis: adjust the pH of the slurry obtained in step (4) to 2.5, add 70 gram...

Embodiment 2

[0043] (1) Pretreatment: Select 20kg of fresh duck breast cartilage, remove the duck meat, fascia and red bone on the cartilage after thawing, and then use a dicing machine to cut into cubes of about 2mm*2mm.

[0044] (2) Degreasing: Use 200 kg of NaOH and 0.9% KCl solution with a final concentration of 0.01%, degrease at room temperature for 6 hours, and then wash with purified water to pH 6.0.

[0045] (3) Disinfection: Add 500ppm sodium hypochlorite solution (containing 100ppm hydrogen peroxide) to start disinfection, disinfect 3 times, each time for 6 hours, after disinfection, wash with purified water until no disinfection and no residual chlorine is detected, and the pH is controlled at 6.5-7.0 .

[0046](4) Homogenate: Add 40 kg of purified water to the cartilage dices processed in step (3), and use a colloid mill to grind the cartilage into about 100-200 mesh.

[0047] (5) Enzymolysis: adjust the pH of the slurry obtained in step (4) to 8.5, add 0.2 g of alkaline prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com