Preparation method for magnesium alloy

A magnesium alloy and intermediate alloy technology, applied in the field of improving its strength and toughness, improving magnesium alloy structure, new magnesium alloy materials and spray forming preparation, can solve the problems of high equipment requirements, difficult to control the preparation process, high production cost, etc., and achieve mechanical Excellent performance, improved strength and toughness, simultaneous improvement of strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

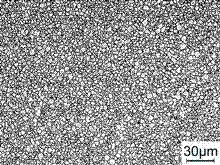

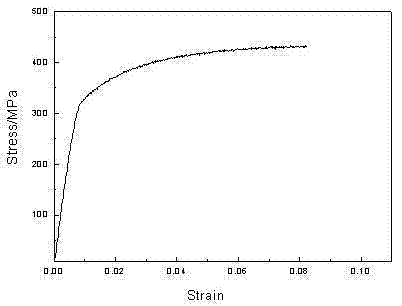

Image

Examples

Embodiment 1

[0014] AZ31 magnesium alloy adopts the following preparation process:

[0015] (1) Preparation of magnesium alloy deposition billet by spray forming

[0016] First place the AZ31 magnesium alloy ingot in the smelting furnace, vacuum the induction furnace, wash the furnace with argon 3 times during this period, when the vacuum reaches 10Pa, fill the vacuum furnace with argon until the absolute value of the vacuum gauge scale is 0.03 When the smelting furnace is powered, the ingot is melted. After the alloy is melted and mixed evenly by electromagnetic stirring, the temperature is lowered to 750°C, poured into the tundish, and flowed out through the diversion nozzle. The high-pressure atomized gas N 2 Atomization, the atomized droplets are deposited on the receiving plate to form a columnar deposition blank. The ring-hole non-restricted atomizing nozzle is adopted, and the specific process parameters are as follows: the atomizing pressure is 0.55MPa, the outlet diameter of the ...

Embodiment 2

[0021] AZ91 magnesium alloy adopts the following preparation process:

[0022] (1) Preparation of magnesium alloy deposition billet by spray forming

[0023] First place the AZ91 magnesium alloy ingot in the smelting furnace, vacuum the induction furnace, wash the furnace 3 times with argon during this period, when the vacuum reaches 30Pa, fill the vacuum furnace with argon until the absolute value of the vacuum gauge scale is 0.03 When the smelting furnace is powered, the ingot is melted. After the alloy is melted and mixed evenly by electromagnetic stirring, it is cooled to 720°C, poured into the tundish, and flows out through the diversion nozzle. The high-pressure atomized gas N 2 Atomization, the atomized droplets are deposited on the receiving plate to form a columnar deposition blank. The ring-hole non-restricted atomizing nozzle is adopted, and the specific process parameters are as follows: the atomization pressure is 0.6MPa, the outlet diameter of the diversion nozz...

Embodiment 3

[0028] Mg-9.0wt.%Al-1.8wt.%Zn alloy adopts the following preparation process:

[0029] (1) Preparation of magnesium alloy deposition billet by spray forming

[0030] First place the AZ91 magnesium alloy ingot in the smelting furnace, vacuum the induction furnace, wash the furnace twice with argon during this period, and when the vacuum reaches 50Pa, fill the vacuum furnace with argon until the absolute value of the vacuum gauge scale is 0.04 At the same time, power is supplied to the melting furnace to melt the ingot. After the alloy is melted, other alloy ingredients (pure zinc block) are added to the melting furnace through the feeding device equipped with the vacuum furnace. Pour into the tundish, flow out through the diversion nozzle, high-pressure atomizing gas N 2 Atomization, the atomized droplets are deposited on the receiving plate to form a columnar deposition blank. The ring-hole non-restricted atomizing nozzle is used, and the specific process parameters are as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com