Method for preparing electrode carbon material of supercapacitor employing radish as carbon source

A technology of supercapacitors and carbon materials, which is applied in the fields of hybrid capacitor electrodes, chemical instruments and methods, and hybrid/electric double layer capacitor manufacturing, etc. Demand and other issues, to achieve the effect of low equipment requirements and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

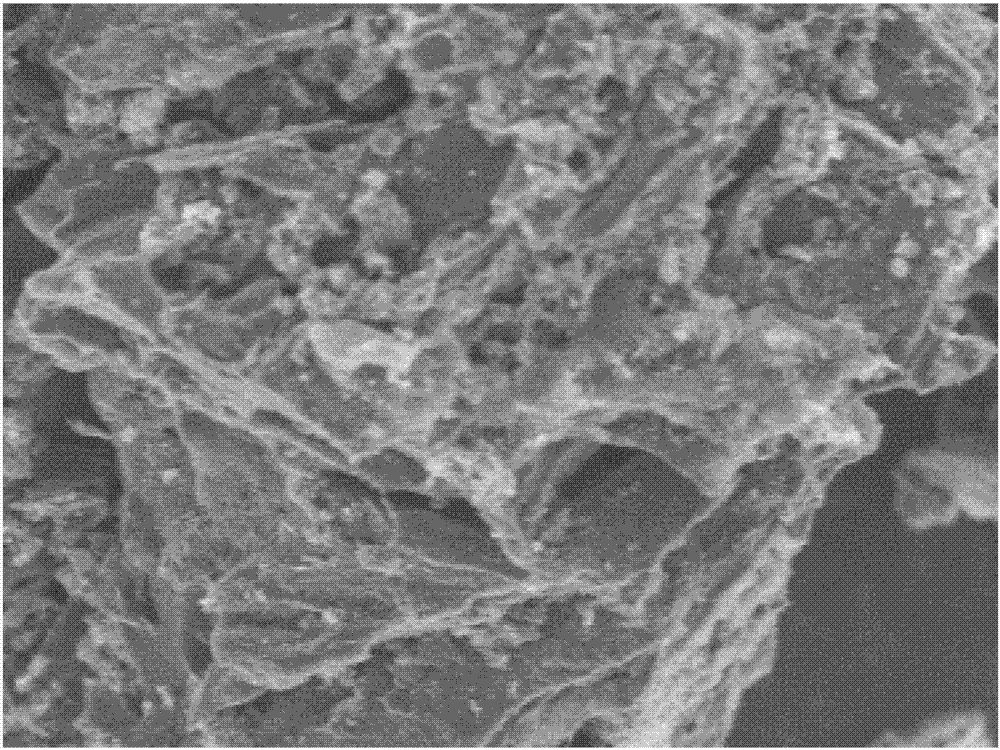

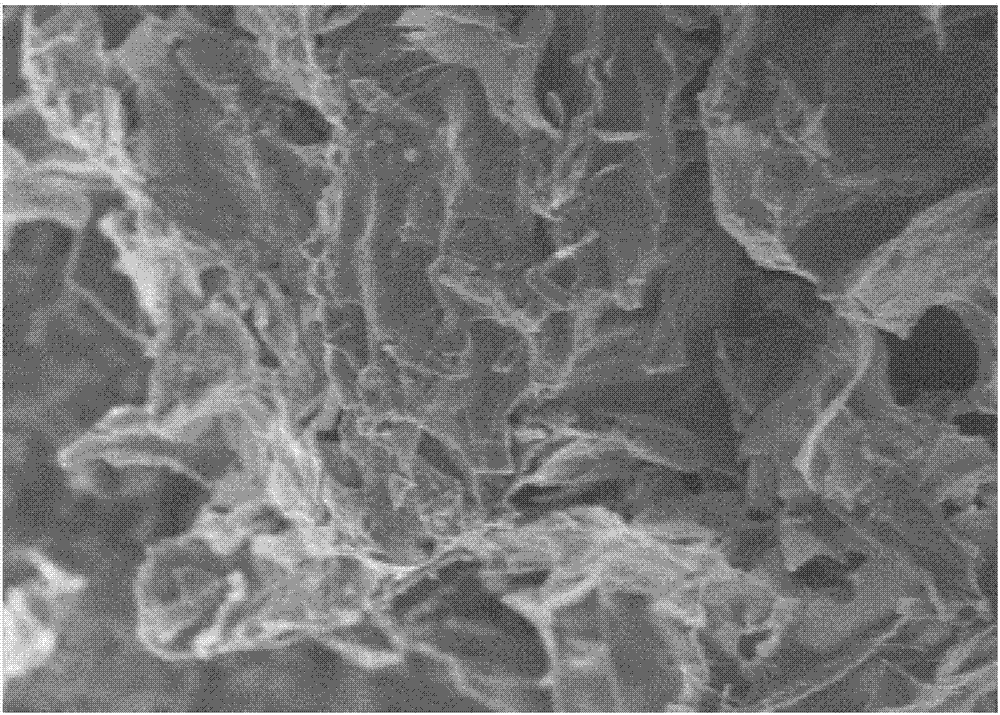

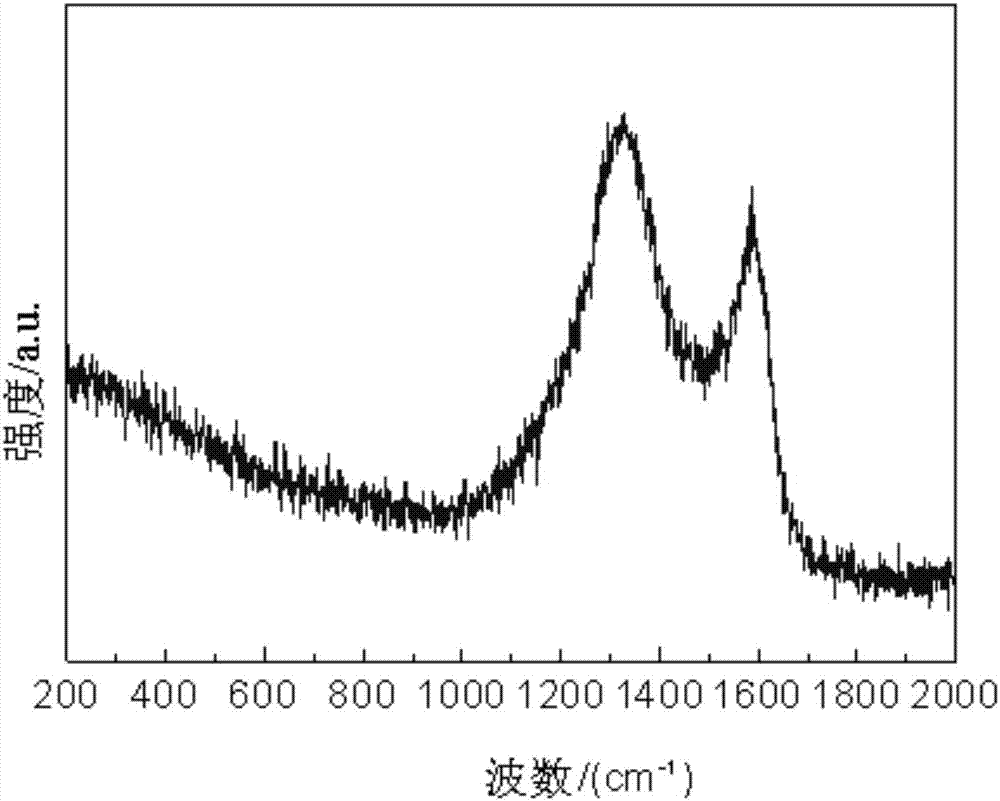

[0021] Specific embodiment one: this embodiment is a kind of method that uses radish as carbon source to prepare supercapacitor electrode carbon material, specifically carries out according to the following steps:

[0022] 1. Freeze-drying radish: put the radish pulp in a freeze-drying machine, and freeze-dry it for 24h-36h at a temperature of -25 to -70°C and a vacuum of 50Pa to 500Pa;

[0023] 2. Pre-carbonization: put the freeze-dried radish in step 1 in a tube furnace, and calcinate for 0.5h-3h under the protection of inert gas and at a temperature of 350°C to 600°C, and then put it in the furnace under the protection of inert gas. Cool to obtain pre-carbonized radish;

[0024] 3. Activation: Add the pre-carbonized radish in step 2 to the aqueous solution of the activator, mix thoroughly, and then heat in an oven at a temperature of 60°C to 110°C for 3h to 12h to obtain the activated product; the activator The solute in the aqueous solution is the mixture of one or more i...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the radish pulp described in step 1 is carrot pulp or white radish pulp. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the inert gas described in step two is a mixture of one or more of nitrogen, helium or argon, and the flow rate of the inert gas is 10mL / min ~500mL / min. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com