Method for preparing furfuryl alcohol by utilizing hydrogen transfer reaction to catalyze furfuraldehyde

A technology of hydrogen transfer and furfural, which is applied in the direction of organic chemistry, can solve the problems of low catalyst activity, mild reaction conditions, and high production safety, and achieve the effect of reusable reaction activity, mild reaction conditions, and low production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

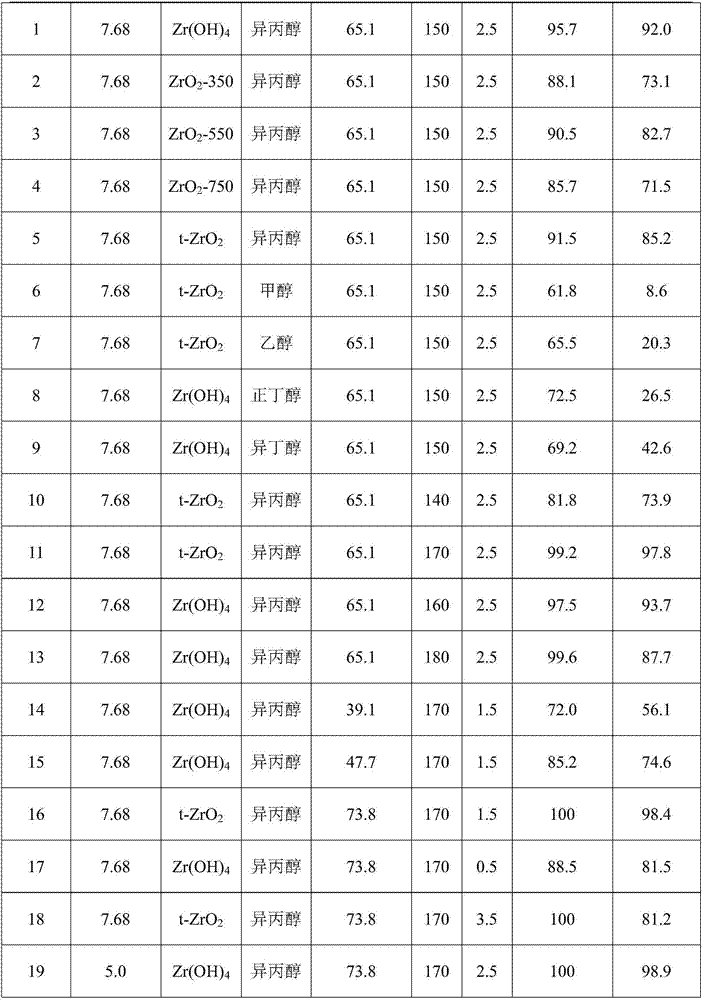

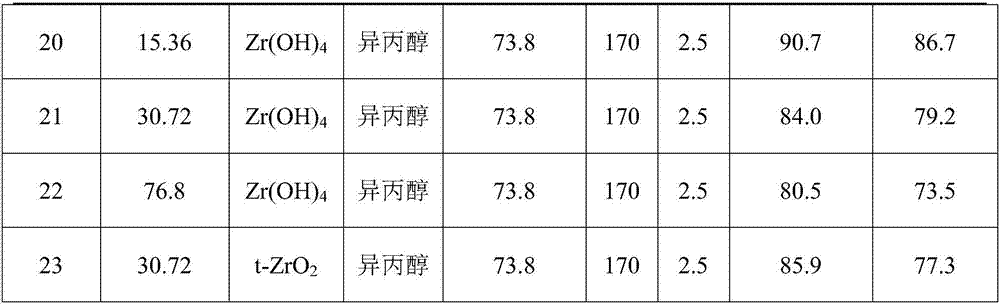

Examples

preparation Embodiment 1

[0016] Preparation Example 1: Preparation of Zirconium Hydroxide

[0017] Add concentrated ammonia water drop by drop to the zirconium oxychloride aqueous solution until the pH of the system reaches 9-10, age the precipitate for 24 hours, and wash it repeatedly with ethanol, then dry the precipitate at 120°C for 12 hours to obtain zirconium hydroxide (Zr(OH) 4 ).

preparation Embodiment 2

[0018] Preparation Example 2: Preparation of Zirconia

[0019] With the Zr(OH) that obtains in the preparation embodiment 1 4 Zirconia (ZrO 2 -x, where x is the calcination temperature).

preparation Embodiment 3

[0020] Preparation Example 3: Preparation of Tetragonal Zirconia

[0021] Take a certain amount of zirconyl nitrate and bake it at 120°C for 12h, and then bake it at 400°C for 3h to get tetragonal zirconia (t-ZrO 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com