Tungsten dioxide modified phenolic resin and production methods of resin, phenolic moulding plastic and automobile switch covers

A technology of phenolic molding compound and phenolic resin, which is applied in the preparation of automobile switch covers, the preparation of tungsten dioxide modified phenolic resin, and the preparation of phenolic molding compound. It can solve the problems of large thermal deformation and poor heat resistance, and achieve operational Convenience and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

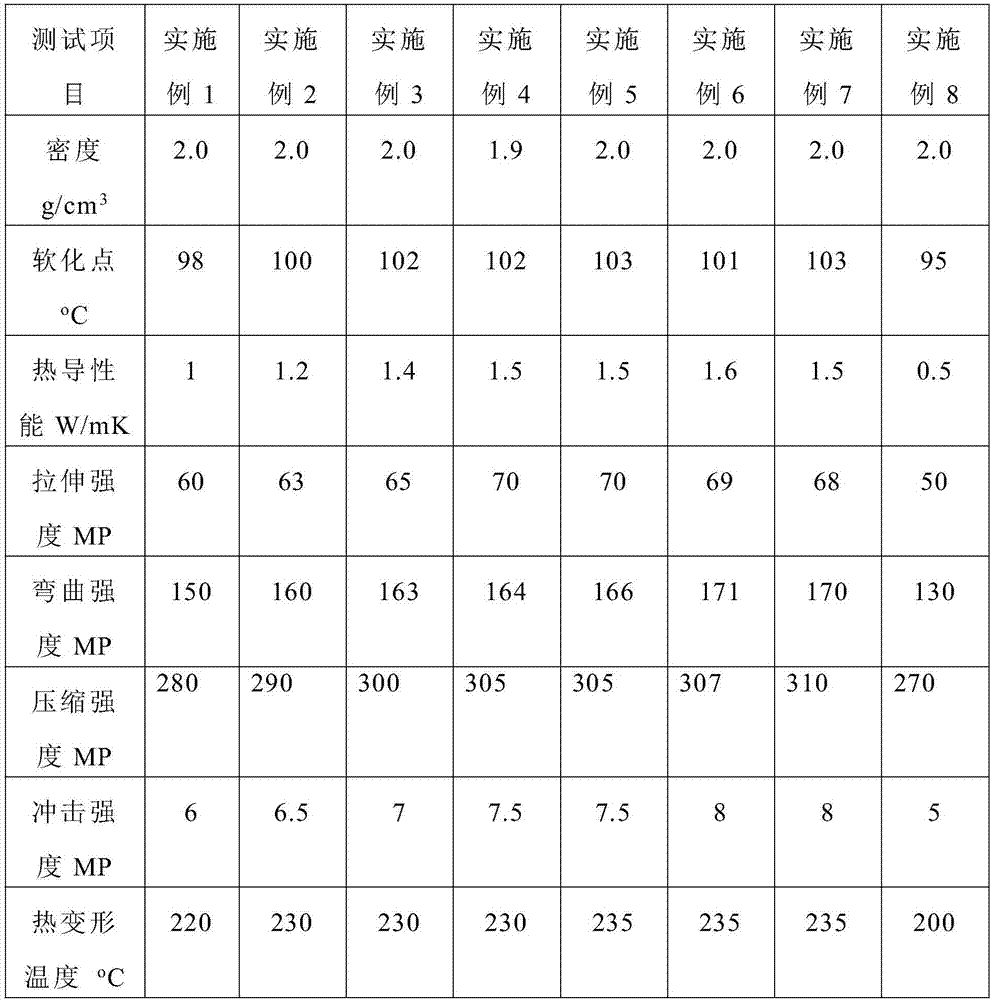

Examples

Embodiment 1

[0029] Embodiment 1: 300g phenol, 160g37% formaldehyde solution, 1.5g oxalic acid are added in the four-necked bottle, and oil bath is heated to 80 ℃; Add 1.5g WS while stirring 2 The nano-sheet material is uniformly dispersed by ultrasonic treatment; keep the temperature at 80°C, ultrasonically react for 1h, stop ultrasonication; add 52g of 37% formaldehyde solution and 0.9g of oxalic acid, raise the temperature to 92°C, and react at constant temperature for 1h 20min, Stop heating; use NaOH aqueous solution to adjust the pH to neutral, lower the temperature to 60°C, and then vacuumize; when the material temperature reaches 90°C, quickly discharge the material to obtain a brown solid product, which is WS after crushing 2 The mass fraction is 0.5% powdered phenolic resin. The above resin is pulverized, mixed with glass fiber, mold release agent, carbon black and filler, extruded and granulated by twin-screw to prepare phenolic molding compound, and injected by an injection mold...

Embodiment 2

[0030] Embodiment 2: Similar to Example 1, the difference is that 300g phenol is used as the benchmark amount, and 3.0g WS is added 2 . Other steps are identical with embodiment 1, obtain WS 2 The phenolic resin with a mass fraction of 1.0% is then post-processed to prepare an automobile switch cover sample.

Embodiment 3

[0031] Embodiment 3: Similar to Example 1, the difference is that 300g phenol is used as the benchmark amount, and 4.5gWS is added 2 . Other steps are identical with embodiment 1, obtain WS 2 The phenolic resin with a mass fraction of 1.5% is then post-processed to obtain a sample of an automobile switch cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com