A kind of highly stable silicate fluorescent powder for LED and preparation method thereof

A high-stability, fluorescent powder technology, applied in chemical instruments and methods, luminescent materials, semiconductor devices, etc., can solve the problems of poor moisture and heat resistance stability, achieve strong moisture and heat resistance, strong stability, and make up for coating defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

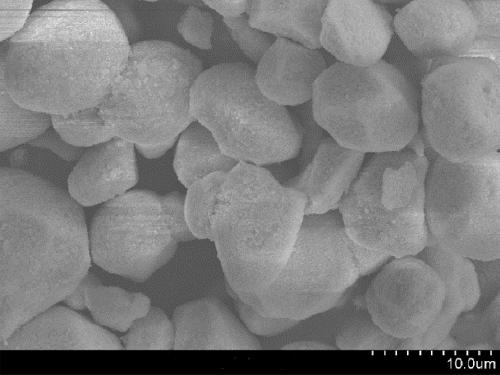

Embodiment 1

[0029] The particle structure of the highly stable silicate phosphor powder used in LEDs provided by the present invention includes three parts, which are respectively the raw phosphor powder located in the center of the particle, the intermediate layer coated on the raw phosphor powder, and the intermediate layer wrapped on the intermediate layer. The outer layer; wherein the raw phosphor is silicate phosphor particles doped with silicate matrix with rare earth ions; its general chemical formula is M x (Si, A 2 )O (2+x) :yEu 2+ ,zA 1 3+ or (Sr,Ba) 3 SiO 5 :nEu 2+ , M in the general chemical formula is at least one of Sr, Ba, Mg, Ca, Zn, Cu, Mn, A 1 At least one of Y, La, Sc, Er, without adding A 2 or A 2 Ge, and 1.9≤x≤2.1, 0.005≤y≤0.2, 0.01≤z≤0.2; 0.005≤n≤0.05; the intermediate layer is formed by dehydrating and drying the coupling mixture coated on the raw phosphor powder cladding layer; its outer layer is HfO 2 film layer.

[0030] The preparation process of the...

Embodiment 2

[0033] (1) Take 1000g of raw phosphor Ba 1.9 Mg 0.05 Zn 0.05 SiO 4 :0.06Eu 2+ ,0.04Y 3+ and 4000mL of alcohol, placed in a roller bottle containing 2kg of corundum balls, milled for 60 minutes with the roller bottle, divided into alcohol for 3 times, dried at 80°C for 60 minutes, and passed through a 200-mesh sieve;

[0034] (2) According to the mass ratio of water: ammonia water: alcohol: silane coupling agent: raw phosphor powder 300:2:100:2:50, take by weighing 500g of sieved raw phosphor powder Ba 1.9 Mg 0.05 Zn 0.05 SiO 4 :0.06Eu 2+ ,0.04Y 3+ , 20g silane coupling agent tetraethyl orthosilicate Si(OC 2 h 5 ) 4 , 1000g alcohol, 20g ammonia water, 3000g water, dilute the ammonia water with water, add the sieved raw phosphor powder in the diluted ammonia water, and then mix the alcohol and ethyl orthosilicate Si(OC 2 h 5 ) 4 After mixing, add it to the aqueous phase mixture of the above-mentioned raw material phosphors, stir for 1 hour, then settle, pour off t...

Embodiment 3

[0037] Its method step is the same as embodiment 2, only the material formula of the intermediate layer in step (2) is different: according to water: ammoniacal liquor: alcohol: silane coupling agent: the mass ratio of raw material fluorescent powder 100:4:20:8:20 weighs Take 200g of sieved raw phosphor powder Ba 1.9 Mg 0.05 Zn 0.05 SiO 4 :0.06Eu 2+ ,0.04Y 3+ , 80g silane coupling agent tetraethyl orthosilicate Si(OC 2 h 5 ) 4 , 200g alcohol, 40g ammonia water, 1000g water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com