Method of degrading petroleum hydrocarbon

A technology for petroleum hydrocarbons and petroleum, which is applied in the field of anaerobic degradation of petroleum hydrocarbons for the screening of methanogenic bacteria, achieving the effects of wide application range, high efficiency, and enhanced processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for degrading petroleum hydrocarbons, comprising the steps of:

[0039] S1. Sampling: collect oilfield production fluid and oily sludge from different areas of the oilfield as samples;

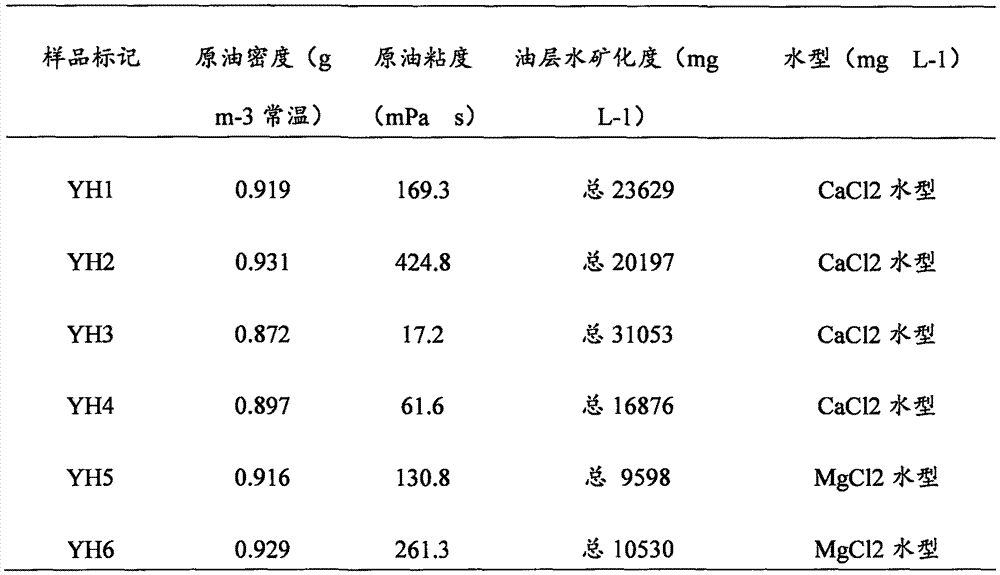

[0040] In this step, six oil well production fluids in an oil field block were collected for research and sampling, and several plastic barrels (about 5L) were filled, and nitrogen was sealed before sampling, and the samples were quickly transported back to the laboratory, stored at low temperature, and numbered They are YH1-YH6; take 4 parts of oily sludge polluted by oil with an oil content of 5.8-11.3% below 30cm from the ground, and store them anaerobically at -5°C after sampling, and they are respectively numbered TH1-TH6; among them, YH1- The physical and chemical properties of YH6 are shown in Table 1.

[0041] Table 1: Physicochemical properties of YH1-YH6

[0042]

[0043] Note 1: YH stands for anaerobic culture oilfield production fluid, and the number behind it ...

Embodiment 2

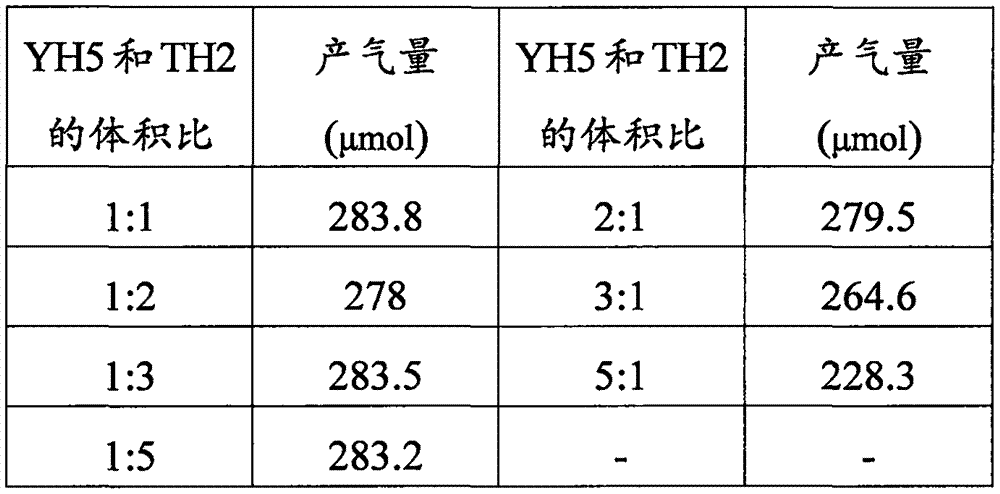

[0080] On the basis of Example 1, the added concentrations of rhamnolipid, SPAN 20, sodium bicarbonate, sodium acetate, sodium molybdate, zinc chloride, sodium sulfate and sodium nitrate described in S6 were changed to be 80mg / L , 3mg / L, 0.8%, 0.9%, 5mg / L, 50mg / L, 600mg / L and 2600mg / L. Other culture conditions remained unchanged. The final methane gas production using different growth activators is shown in Table 4.

Embodiment 3

[0082] On the basis of Example 1, the added concentration of rhamnolipid, SPAN 20, sodium bicarbonate, sodium acetate, sodium molybdate, zinc chloride, sodium sulfate and sodium nitrate described in S6 was changed to be 40 mg / L , 1mg / L, 1%, 0.8%, 4mg / L, 40mg / L, 900mg / L and 4000mg / L. Other culture conditions remained unchanged. The final methane gas production using different growth activators is shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com