Preparation method of epoxy acrylic acid extraction resin and application of epoxy acrylic acid extraction resin to extraction and separation of germanium

An epoxy acrylic acid extraction resin and epoxy acrylic acid extraction technology are applied in the field of germanium extraction and separation, which can solve the problems of extraction agent loss and achieve the effects of less extraction agent loss, simple synthesis method, and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

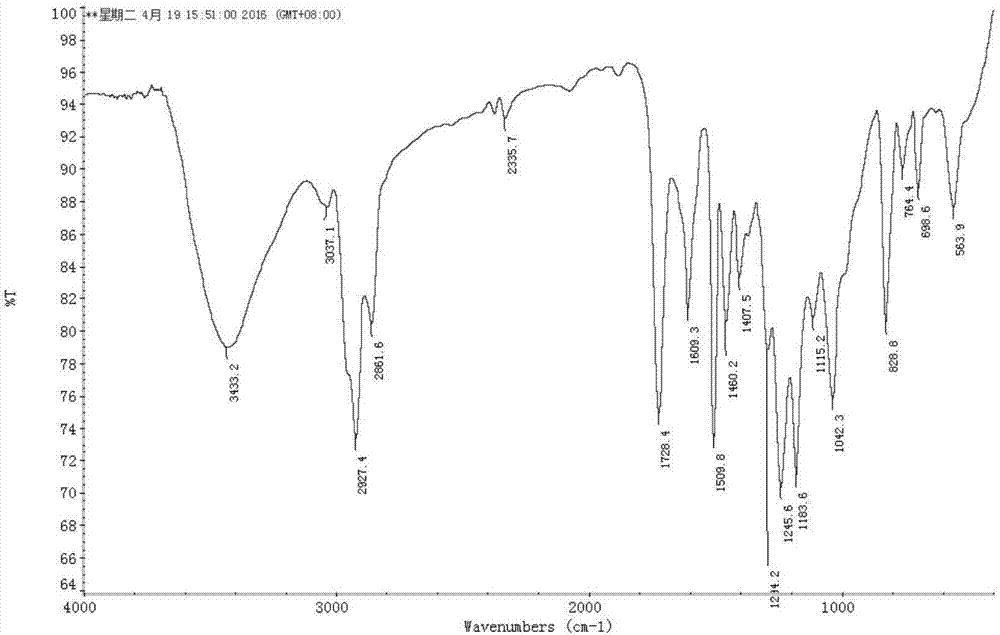

[0025] 1) Preparation of epoxy acrylic resin: Add 1-100 parts of epoxy resin to the device, then add 0.01-1 part of polymerization inhibitor p-methoxyphenol, 0.01-1 part of benzyldimethylamine, stir and heat up to After 80°C, use a constant pressure dropping funnel to add 1 to 50 parts of acrylic acid dropwise, and drop it within 1-2 hours, then raise the temperature to 100°C for 4-5 hours, and stop the reaction after the acid value is less than 10. Cool down to 80°C, add 1-50 parts of styrene, and stir for 100-120 minutes to prepare epoxy acrylic resin for later use.

[0026] 2) Preparation of epoxy acrylic acid extraction resin: Add 1-100 parts of deionized water, 1-10 parts of magnesium chloride solution, 1-20 parts of sodium hydroxide solution in sequence in the device, stir evenly, heat up to 75°C, and fully react 10-20 minutes, then use the constant pressure dropping funnel to add 1-50 parts of epoxy acrylic resin that has been prepared, 1-50 parts of extraction agent N2...

Embodiment 1

[0030] The preparation of embodiment 1 bisphenol A epoxy acrylic acid extraction resin

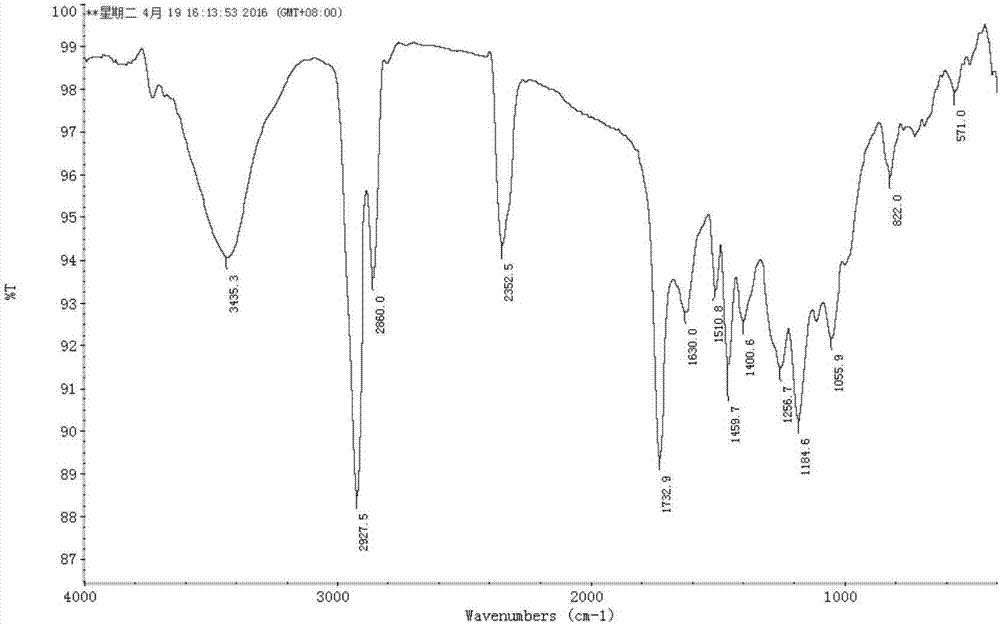

[0031] 1) Add 58.05g of bisphenol A epoxy resin into the device, then add 1.20g of p-methoxyphenol, 0.27g of benzyldimethylamine, stir and heat up to 80°C, then add 19.45g of it dropwise with a constant pressure dropping funnel Add acrylic acid dropwise within 1-2 hours, then raise the temperature to 100°C for 4-5 hours, stop the reaction after the acid value is less than 10, drop the temperature to 80°C, add 33.45g styrene, and stir for 100- 120min, prepared bisphenol A epoxy acrylic resin for subsequent use.

[0032] 2) Add 58ml of deionized water, 2.5ml of magnesium chloride solution (1mol / L), and 5ml of sodium hydroxide solution to the device in turn, stir evenly, heat up to 75°C, fully react for 10-20 minutes, and then use a constant pressure dropping funnel Add 10g of prepared bisphenol A epoxy acrylic resin dropwise, 10g of extractant N235, the mixed solution of 9.5g of TMPTA and N...

Embodiment 2

[0034] The preparation of embodiment 2 E51 epoxy acrylic extraction resin

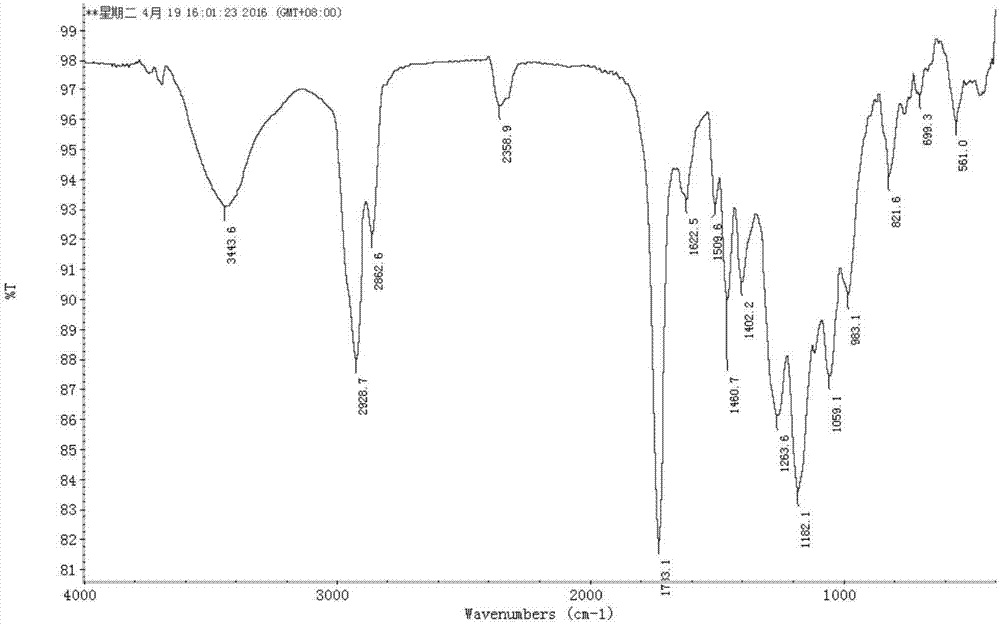

[0035] 1) Add 58.80g of E51 epoxy resin to the device, then add 0.12g of p-methoxyphenol, 0.17g of triethylbenzyl ammonium, stir and raise the temperature to 80°C, add 19.45g of acrylic acid dropwise with a constant pressure dropping funnel , and drop it within 1-2h, then raise the temperature to 110°C and react for 4-5h, after the acid value is less than 10, stop the reaction, cool down to 60°C, add 34.50g of styrene, and stir for 30-60min , to prepare E51 epoxy acrylic resin for subsequent use.

[0036] 2) Add 58ml of deionized water, 2.5ml of magnesium chloride solution (1mol / L), and 5ml of sodium hydroxide solution to the device in turn, stir evenly, heat up to 75°C, fully react for 10-20 minutes, and then use a constant pressure dropping funnel Add 20g of prepared E51 epoxy acrylic resin, 20g of extractant N235, 9.2g of TMPTA and N-methylimidazolium rhenium ionic liquid dropwise, and then add 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com