Long-pulse high-power ion source electrode grid cooling water circuit and vacuum sealing structure

A vacuum-sealed structure and cooling waterway technology, which is applied in the direction of circuits, ion beam tubes, discharge tubes, etc., can solve the problems of high compactness requirements and the inability of the cooling structure to apply to neutral beam ion sources, so as to reduce processing costs and save space, size reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

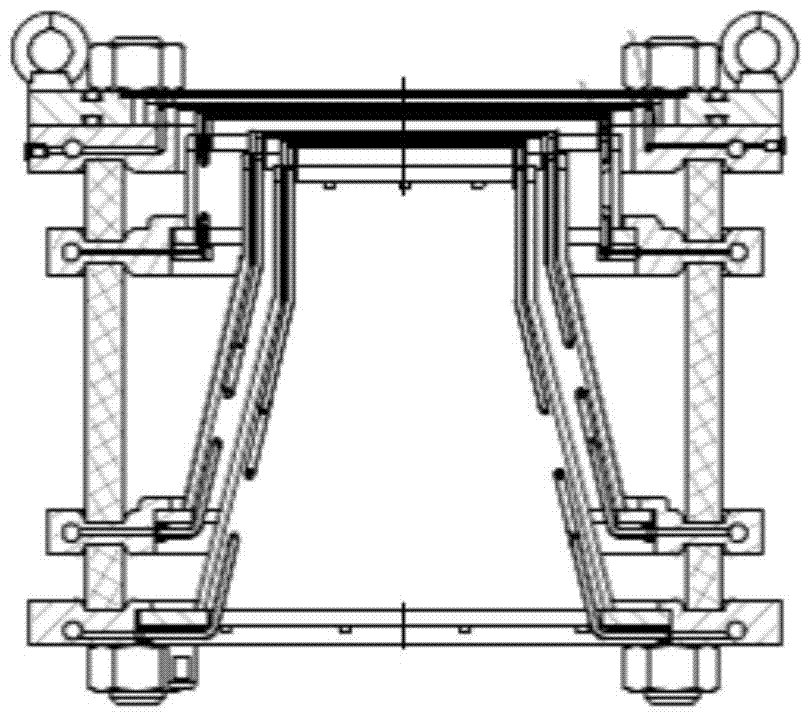

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

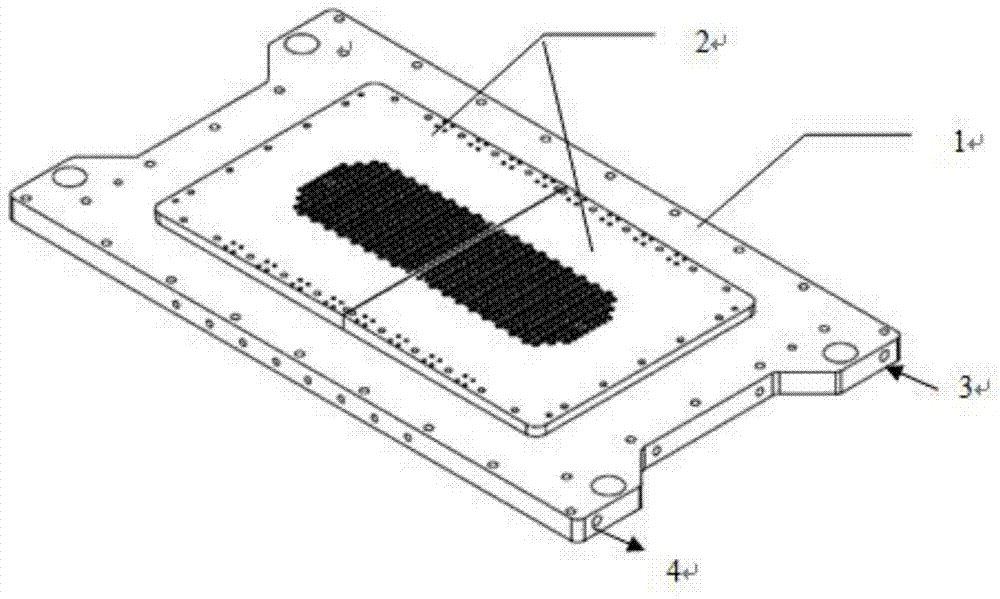

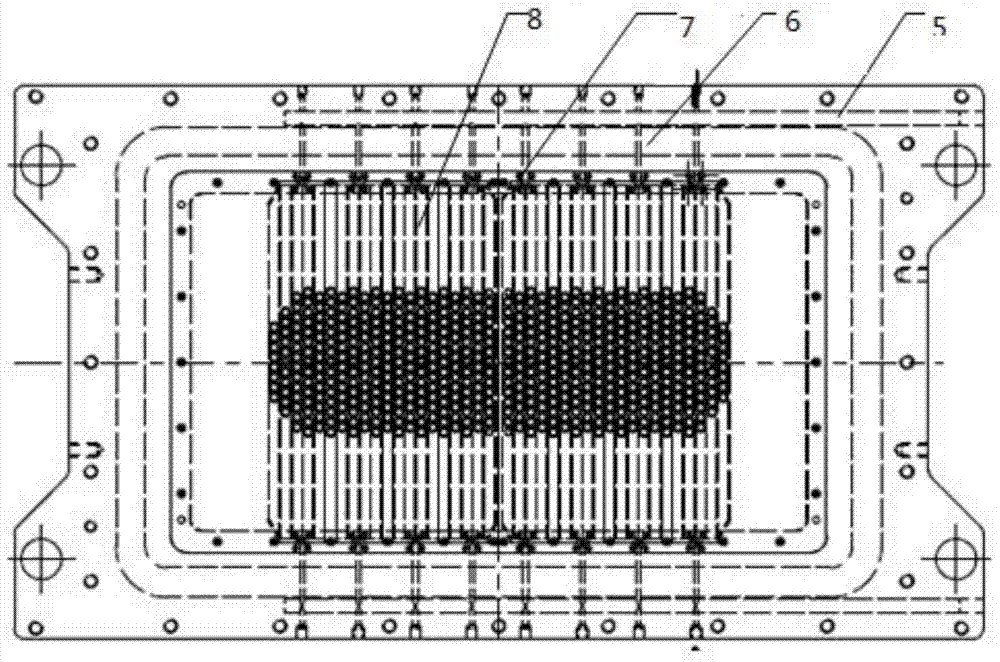

[0022] The high-power ion source electrode system is composed of multi-layer water-cooled electrode grids 2 and their supporting flanges 1. Each layer of water-cooled electrode plates is composed of two overlapping water-cooled electrode grids 2 with the same structure. The first layer of electrode grids has the largest area , the thickness is the smallest, this embodiment takes the first electrode water channel structure of the HL-2M tokmak neutral beam ion source circular hole four-electrode system as an example.

[0023] This waterway structure consists of two main parts, one is the supporting flange 1 with 2 main waterways and 16 branch waterways inside, and the other is a large-area thin-walled flange with 16 main waterways and 40 branch waterways inside. Water-cooled electrode grid 2. The water channel is arranged parallel to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plane size | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com