Carbon fiber heat generation cable for underfloor heating

A carbon fiber heating and carbon fiber technology, applied in the direction of electric heating devices, electrical components, ohmic resistance heating, etc., can solve the problems of easy generation of electromagnetic radiation, adverse effects of pregnant women, improper technical treatment, etc., achieve good thermal conductivity and heat conversion efficiency, improve Thermal conductivity and heat conversion rate, and the effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

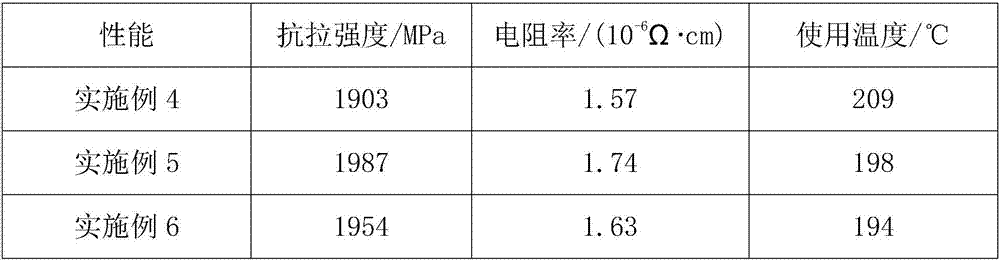

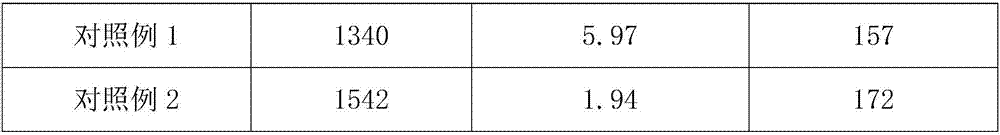

Examples

Embodiment 1

[0019] A carbon fiber heating cable for floor heating, comprising a carbon fiber composite core material and a resin layer, an insulating layer, and an outer skin protection layer wrapped in sequence on the carbon fiber composite core material; the carbon fiber composite core material is formed by twisting modified carbon fiber bundles and alloy wires, The modified carbon fiber bundle is made of zinc oxide whisker modified PAN-based carbon fiber.

Embodiment 2

[0021] A carbon fiber heating cable for floor heating, comprising a carbon fiber composite core material and a resin layer, an insulating layer, and an outer skin protection layer wrapped in sequence on the carbon fiber composite core material; the carbon fiber composite core material is formed by twisting modified carbon fiber bundles and alloy wires, The modified carbon fiber bundle is made of zinc oxide whisker modified PAN-based carbon fiber;

[0022] Among them, the raw materials of the carbon fiber composite core material include by weight: 10 parts of zinc oxide whiskers, 20 parts of cellulose ether, 30 parts of chopped carbon fiber, 15 parts of aramid fiber, 3 parts of binder, 20 parts of solvent; The ether is methyl hydroxypropyl cellulose ether.

Embodiment 3

[0024] A carbon fiber heating cable for floor heating, comprising a carbon fiber composite core material and a resin layer, an insulating layer, and an outer skin protection layer wrapped in sequence on the carbon fiber composite core material; the carbon fiber composite core material is formed by twisting modified carbon fiber bundles and alloy wires, The modified carbon fiber bundle is made of zinc oxide whisker modified PAN-based carbon fiber;

[0025] Among them, the raw materials of the carbon fiber composite core material include by weight: 20 parts of zinc oxide whiskers, 15 parts of cellulose ether, 60 parts of chopped carbon fiber, 10 parts of aramid fiber, 8 parts of binder, 30 parts of solvent; The ether is hydroxyethyl cellulose ether; the binder is phenolic resin; the solvent is acetone; and the metal wire is composed of 0.7% nickel, 0.5% germanium, 0.08% thallium, and the rest is copper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com