Connecting method for magnetic pulse forming auxiliary brazing metal pipes

A technology for magnetic pulse forming and metal pipe fittings, which is applied in welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult welding of large-size pipe fittings, etc., and achieve the goals of improving brazing efficiency, facilitating automatic production, and promoting energy saving and emission reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A method for connecting aluminum alloy and copper pipe fittings assisted by magnetic pulse forming, using an aluminum alloy pipe with an outer diameter of 20mm, an inner diameter of 18mm, and a wall thickness of 1mm and a copper pipe with an outer diameter of 15mm, an inner diameter of 11mm, and a wall thickness of 2mm as two A kind of base material, the Zn-3wt%Al foil that thickness is 0.15mm is brazing material, and CsAlF is brazing flux, and concrete brazing method comprises the following steps:

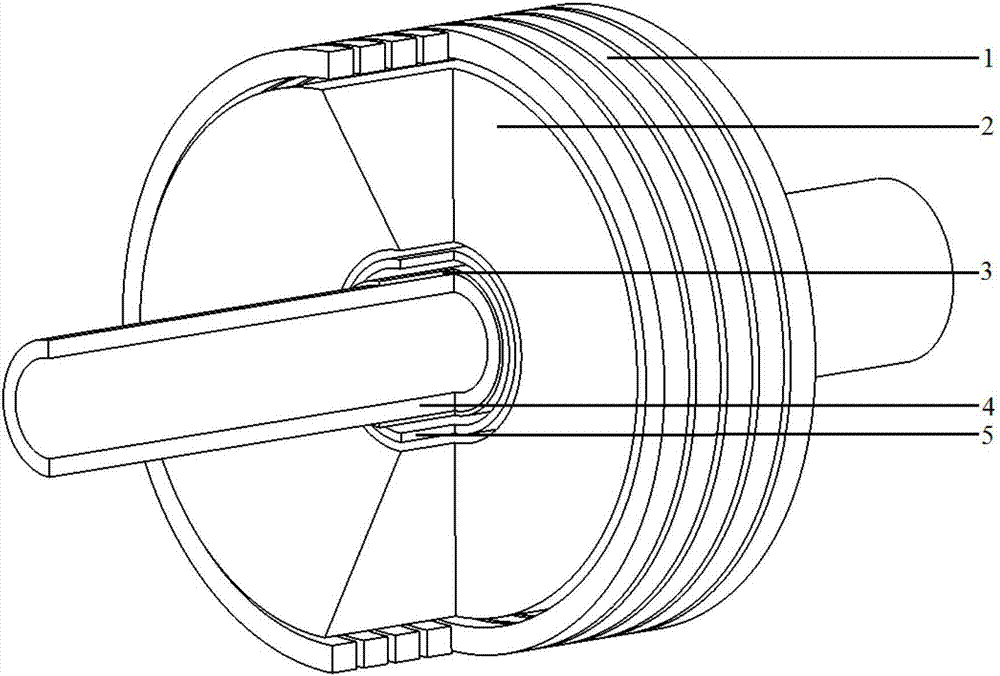

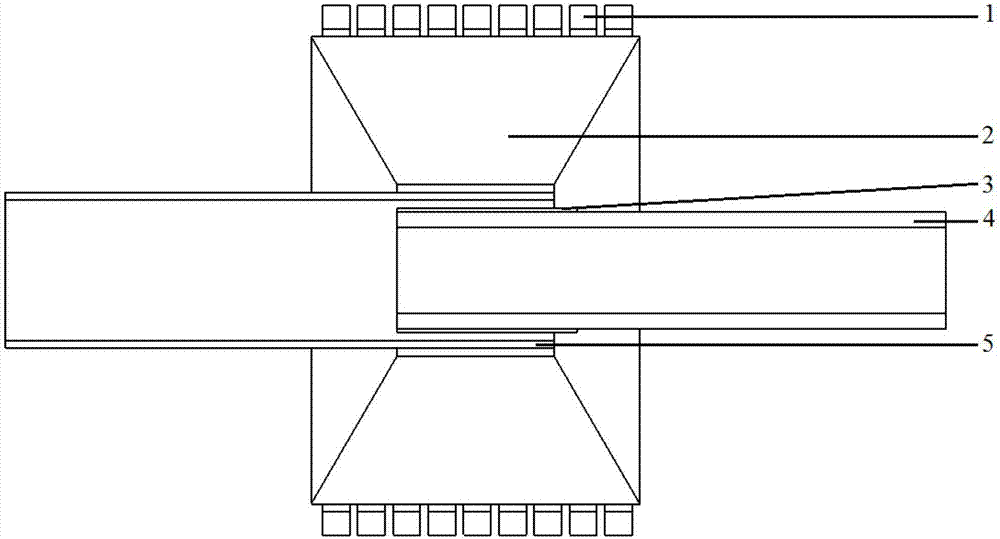

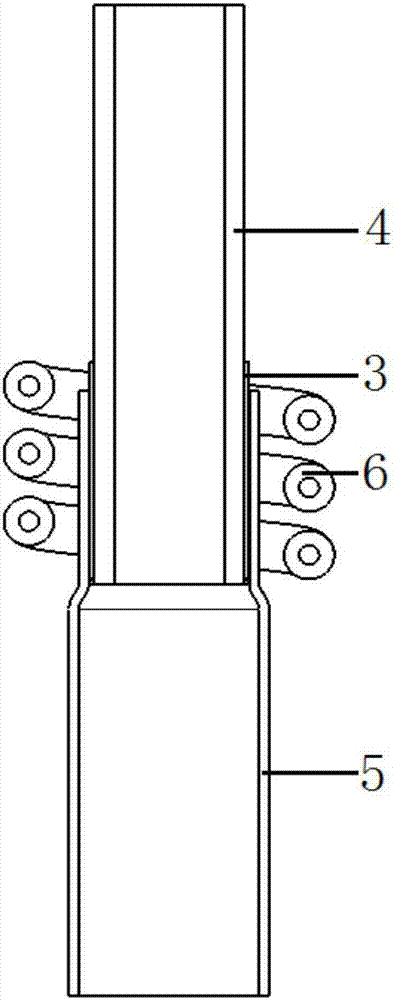

[0073] (1) if figure 1 and figure 2 As shown, take one base material 1 (aluminum alloy tube) and one base material 2 (copper tube), their dimensions are respectively De20mm×1mm and De15mm×2mm, and take Zn-3wt%Al brazing filler metal foil (melted The temperature is 380℃~400℃) and its size is 25mm×47.1mm×0.15mm; at this time, the base metal 1 is the outer tube, and the base metal 2 is the inner tube. Wrapping the brazing material foil on the base metal 2 requires brazing T...

Embodiment 2

[0077] A connection method for brazing aluminum alloy and copper pipe fittings assisted by magnetic pulse forming, using a copper tube with an outer diameter of 20mm, an inner diameter of 18mm, and a wall thickness of 1mm, and an aluminum alloy pipe with an outer diameter of 15mm, an inner diameter of 11mm, and a wall thickness of 2mm. A kind of base material, the Zn-3wt%Al foil that thickness is 0.15mm is brazing material, and CsAlF is brazing flux, and concrete brazing method comprises the following steps:

[0078] (1) if figure 1 and figure 2 As shown, take one base material 1 (copper tube) and one base material 2 (aluminum alloy tube), and their dimensions are respectively De20mm×1mm and De15mm×2mm, and take Zn-3wt%Al solder foil (melted The temperature is 380℃~400℃) and its size is 25mm×47.1mm×0.15mm; at this time, the base metal 1 is the outer tube, and the base metal 2 is the inner tube. Wrapping the brazing material foil on the base metal 2 requires brazing Then imm...

Embodiment 3

[0082]A method for connecting aluminum alloy and copper pipe fittings assisted by magnetic pulse forming, using a copper pipe with an outer diameter of 20mm, an inner diameter of 18mm, and a wall thickness of 1mm and an aluminum alloy pipe with an outer diameter of 15mm, an inner diameter of 11mm, and a wall thickness of 2mm as two A kind of base material, the pure tin foil sheet that thickness is 0.2mm is brazing filler metal, and CsAlF is brazing flux, and concrete brazing method comprises the following steps:

[0083] (1) if figure 1 and figure 2 As shown, take one base material 1 (copper tube) and one base material 2 (aluminum alloy tube). , whose size is 25mm×47.1mm×0.2mm; at this time, the base metal 1 is the outer tube, and the base metal 2 is the inner tube, and the brazing material foil is wrapped around the tube wall port of the base metal 2 that needs to be brazed, and then the base metal 1 and the base metal 2 wrapped with the brazing foil are immersed in the Cs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com