Nano-epoxy glass low-resin powder mica tape and preparation method thereof

A technology of epoxy glass and mica tape, which is applied in the direction of mica, chemical instruments and methods, glass/slag layered products, etc., can solve problems such as unsatisfactory effects, achieve powder drop phenomenon, compact structure, and improve electrical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

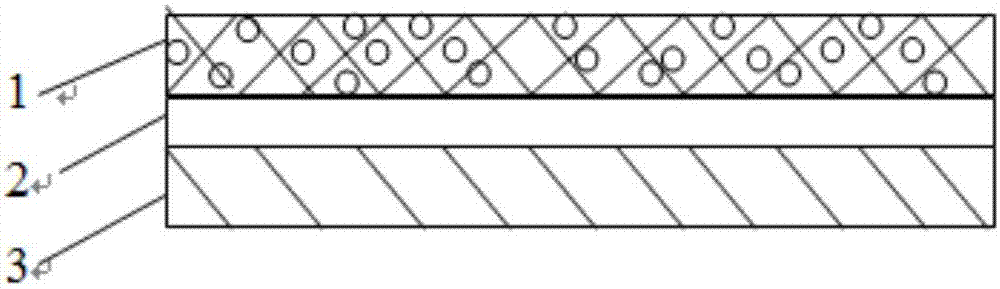

Embodiment 1

[0029] A kind of nano epoxy glass less glue powder mica tape of the present invention, its cross-sectional structure diagram is as follows figure 1 As shown, the nano epoxy glass less glue powder mica tape has a layered structure, from top to bottom, mainly composed of a reinforcing material layer 1, an adhesive layer 2 and a mica paper layer 3; wherein the reinforcing material layer 1 is nano Electrotechnical alkali-free glass cloth treated by particle modification, nano particles are Al with a mass ratio of 20:80 2 O 3 And SiO 2 Mixture, the mass content of nanoparticles in the mica tape is 8%, and the quantitative value of the electrical alkali-free glass cloth is 22g / m 2 ; Mica paper layer 3 is type 507 non-calcined mica paper, and its mica weight is 160g / m 2 The adhesive layer 2 is a mixed epoxy resin layer of E-44, E-20 and F-51, and the mass content of the adhesive layer 2 in the mica tape is 8%; the mica tape has a thickness of 0.15 mm.

[0030] The preparation method of th...

Embodiment 2

[0040] A kind of nano epoxy glass less glue powder mica tape of the present invention, its cross-sectional structure diagram is as follows figure 1 As shown, the nano epoxy glass less glue powder mica tape has a layered structure, from top to bottom, mainly composed of a reinforcing material layer 1, an adhesive layer 2 and a mica paper layer 3; wherein the reinforcing material layer 1 is nano Electrotechnical alkali-free glass cloth treated by particle modification, nano particles are Al with a mass ratio of 30:70 2 O 3 And SiO 2 Mixture, the mass content of nanoparticles in the mica tape is 8%, and the quantitative value of the electrical alkali-free glass cloth is 22g / m 2 ; Mica paper layer 3 is 507 type non-calcined mica paper, and its mica basis weight is 155g / m 2 The adhesive layer 2 is an E-44 and E-20 mixed epoxy resin layer, and the mass content of the adhesive layer 2 in the mica tape is 7.5%; the mica tape has a thickness of 0.14 mm.

[0041] The preparation method of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com