Continuous heat-pipe roller vacuum drying machine

A drum vacuum and drying machine technology, applied in non-progressive dryers, drying solid materials without heating, dryers, etc., can solve the problem of inability to continuously vacuum dry materials, affect the drying quality of materials, and effectively heat energy Problems such as low utilization rate can achieve the effect of optimizing drying quality, improving effective utilization rate and reducing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

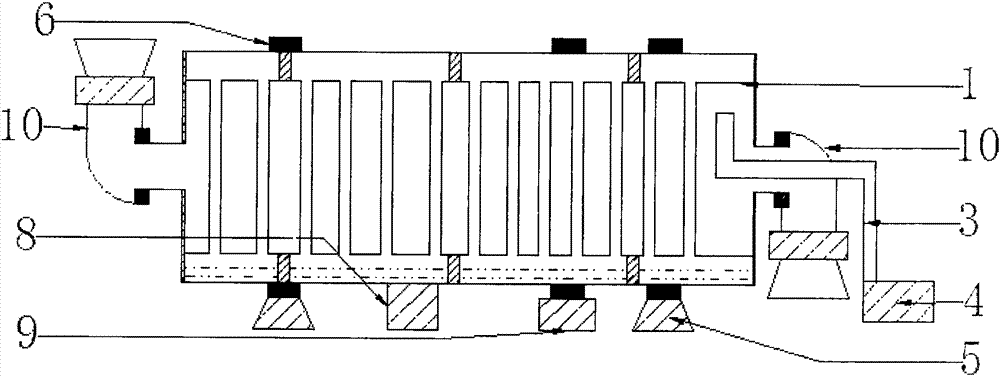

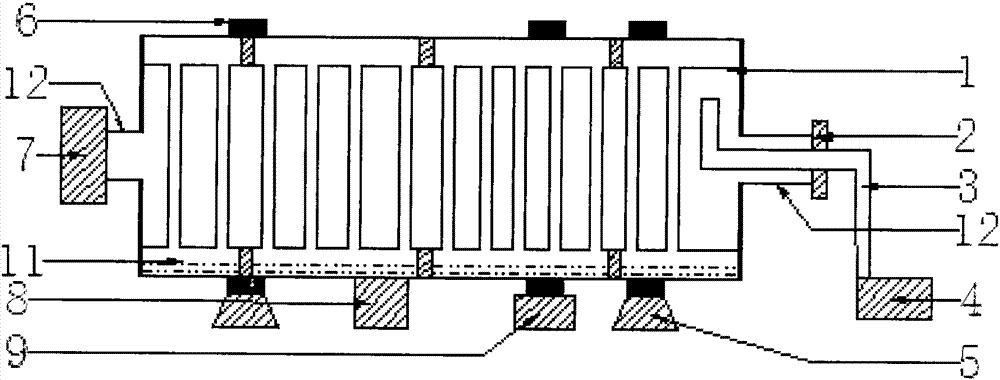

[0043] Such as figure 1 The shown continuous heat pipe drum vacuum dryer is composed of a circulating heat pipe drum vacuum dryer and a highly airtight unloading device (10).

[0044] The high airtight unloading device (10) is installed on the inlet and outlet (12) of the circulating heat pipe drum vacuum dryer.

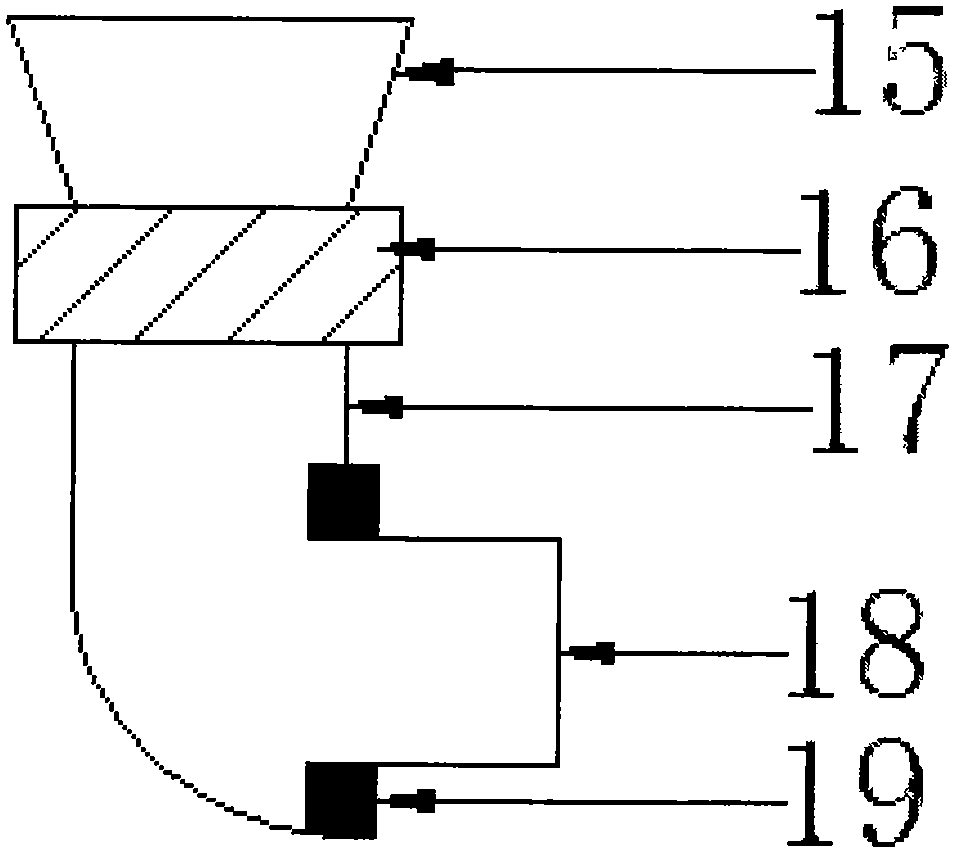

[0045] Such as figure 2 The shown high airtight unloading device (10) is made up of unloading device (16), elbow (17), sealing device (19), hopper (15) and conduit (18).

[0046] One end of the elbow (17) is connected to the discharge device (16), and the other end of the elbow (17) is connected to the conduit (18).

[0047] The conduit (18) and the elbow (16) are fixedly connected and sealed by a sealing device (19); the elbow (16) and the discharge device (18) are fixedly connected by a flange.

[0048] One end of the discharge device (18) is connected to the elbow (16), and the other end of the discharge device (18) is connected to the hopper (15).

[0049] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com