Black cereal sour-milk and preparation method thereof

A grain, black technology, applied in the field of fermented dairy product processing, to achieve the effects of delicate taste, excellent sensory quality and stability, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

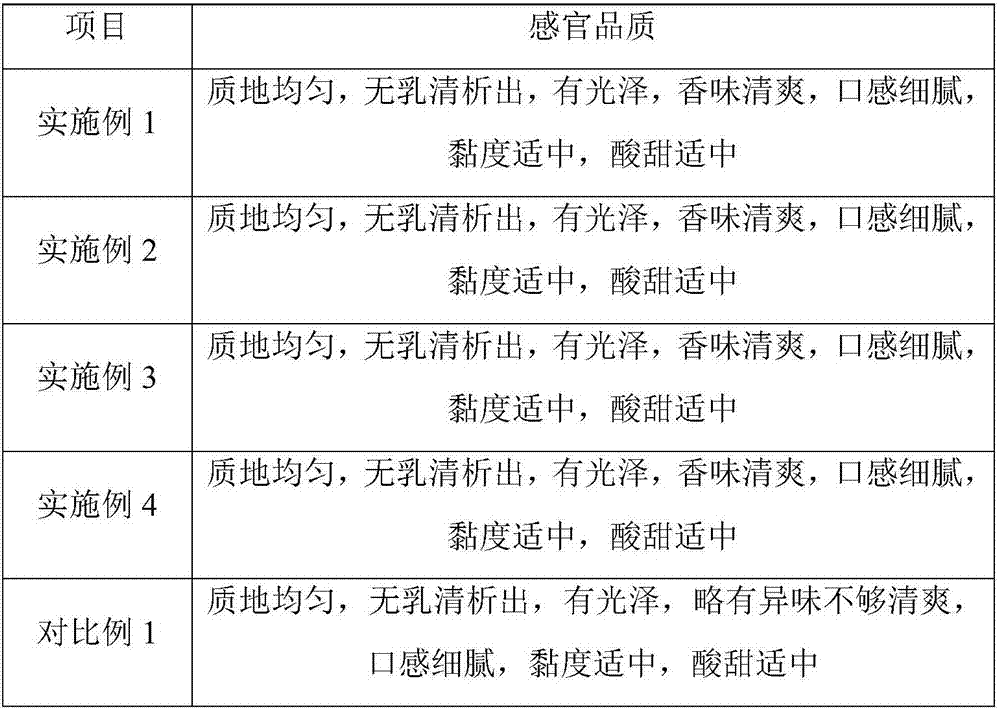

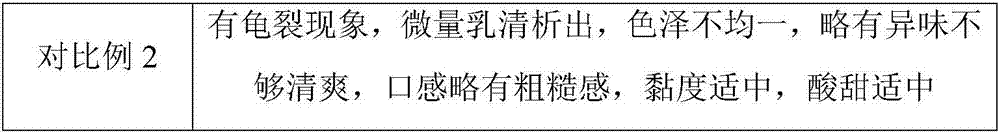

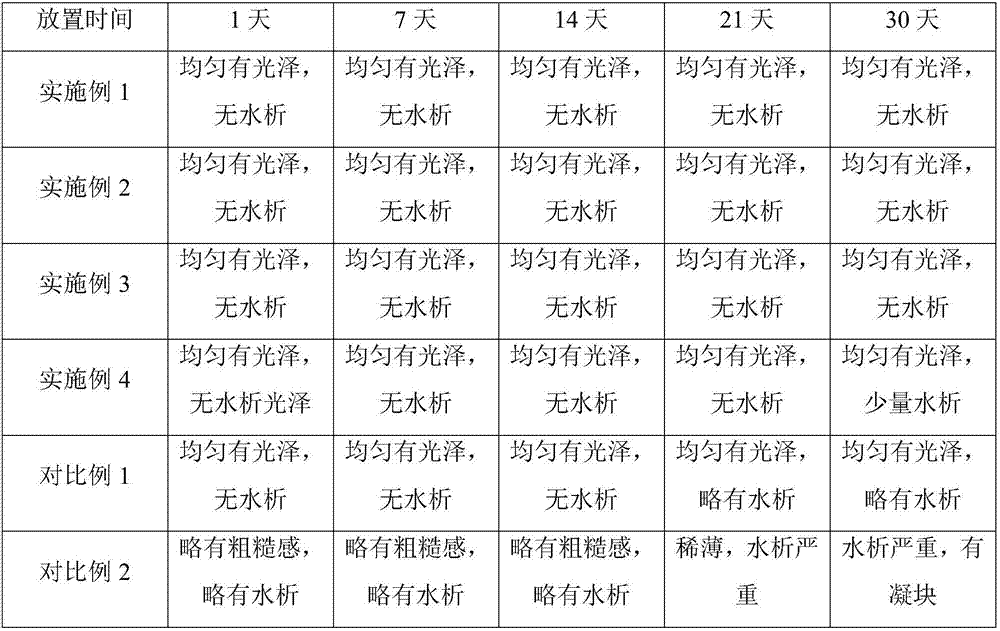

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the above-mentioned black cereal yoghurt, comprising the following steps:

[0036] (1) prepare black grain composite pulp;

[0037] It specifically includes the preparation of black soybean milk, mixed powder and black grain compound pulp:

[0038] (1-1) Preparation of black soybean milk: fully soak the black soybeans in water, optionally in warm water at 30-45°C, usually for 5-24 hours, and then filter to obtain soaked black soybeans, which are subjected to microwave treatment for 1-24 hours. 3min, then add water to mix and refine, and optionally filter with 100-200 mesh to obtain black soybean milk; according to the present invention, when mixing and refining, the amount of water added is 2 to 5 times the mass of black beans, based on the mass of black beans before soaking.

[0039] (1-2) Preparation of mixed powder: mix and pulverize dried black rice, rye, black sesame and black wolfberry, and optionally sie...

Embodiment 1

[0049] The stirred black cereal yoghurt provided in this embodiment is made of the following raw materials in parts by weight, with 0.5 kg as one part by weight:

[0050] 850 parts of raw milk (425kg), 80 parts of black cereal compound pulp, 5 parts of whey protein powder, 62 parts of sweetener (62 parts of xylitol), 5 parts of stabilizer (1 part of gelatin, 1 part of pectin and denatured 3 parts of starch); black cereal compound pulp is made by mixing black soybean milk and mixed powder at a mass ratio of 2:1, black soybean milk is made by mixing black soybeans with purified water twice the quality, and mixed powder is made of black rice, rye , black sesame and black wolfberry are mixed and crushed at a mass ratio of 1:0.5:0.2:0.1.

[0051] The preparation process is as follows:

[0052] (1) Preparation of black soybean milk: select black soybeans with uniform and plump particles, soak them in warm water at 35°C for 10 hours, filter them, and treat the soaked black soybeans ...

Embodiment 2

[0061] The solidified black cereal yogurt provided in this embodiment is made of the following raw materials in parts by weight, with 0.5 kg as one part by weight:

[0062] 820 parts of raw milk (410kg), 100 parts of black cereal compound pulp, 5 parts of whey protein powder, 70 parts of sweetener (20 parts of xylitol, 20 parts of isomaltooligosaccharide and 30 parts of soybean oligosaccharide), stable 3 parts of agent (2 parts of gelatin and 1 part of pectin). Black grain compound pulp is made by mixing black soybean milk and mixed powder at a mass ratio of 2:1. Black soybean milk is made by mixing and refining black beans with 2 times the quality of purified water. Lycium barbarum is mixed and pulverized at a mass ratio of 1:1.2:0.5:0.3.

[0063] The preparation process is as follows:

[0064] (1) Preparation of black soybean milk: select black soybeans with uniform and plump particles, soak them in warm water at 35°C for 10 hours, filter them, and treat the soaked black s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com